Webbing is the unsung hero of countless industrial and consumer products—from backpack straps and safety harnesses to pet leashes and cargo tie-downs. Choosing the right cutting method directly impacts product quality, production speed, and overall cost. In this exploration of automated vs manual webbing cutting, we’ll unpack the strengths and weaknesses of each approach, reveal critical decision-making factors, and share actionable best practices gleaned from over 18 years of Szoneier’s webbing R&D and manufacturing expertise.

Automated cutting leverages CNC-driven and hot-knife systems to deliver high precision, consistent edge sealing, and rapid throughput, ideal for large-scale production. Manual cutting, using hand tools like scissors and handheld hot cutters, offers budget-friendly flexibility for small batches but may sacrifice uniformity and speed.

Imagine a busy factory where custom polyester webbing rolls through precision hot-knife cutters at 120 meters per minute, each slice sealed instantly to prevent fraying. Contrast that with a skilled operator, carefully measuring and trimming a bespoke patterned cotton webbing sample—each snip tailored to a designer’s exact specifications. Which method reigns supreme? Read on to discover how to strike the perfect balance between automation and craftsmanship for your next webbing order.

What Is Automated Webbing Cutting and How Does It Work?

Automated webbing cutting uses CNC-controlled machines—like continuous hot-knife cutters or roller-fed batch cutters—to slice webbing with pinpoint accuracy and seal edges in one pass. These systems excel in high-volume environments, ensuring uniform lengths, preventing fraying on synthetic webbings, and reducing labor costs through rapid, repeatable operations.

Automated webbing cutting encompasses a variety of machine styles, each tailored to different production scales and material types:

Continuous Hot-Knife Cutters

- Mechanism: A heated blade travels laterally across moving webbing, simultaneously cutting and heat-sealing edges.

- Ideal For: Nylon, polyester, and PP webbings prone to fraying.

- Throughput: Up to 150 meters per minute, depending on material thickness and blade temperature.

- Advantages: Consistent seal quality, negligible fray, minimal secondary processing.

Roller-Fed Batch Cutters

- Mechanism: Foot-pedal or servo-motor-driven blades cut fixed lengths from webbing rolls fed through rollers.

- Ideal For: High-volume runs of uniform straps (e.g., backpack shoulder straps).

- Throughput: 50–100 cuts per minute, programmable to custom lengths with digital controls.

- Advantages: Precise length control, fast changeover between lengths, lower initial cost than CNC systems.

CNC Shear Slitting Machines

- Mechanism: Shear blades slice through multiple layers or widths of webbing in a single stroke—often used for cutting webbing panels or wide belts into narrower strips.

- Ideal For: Cotton and mixed-fiber webbings that don’t require heat sealing.

- Throughput: Varies by blade count; multi-blade slitting can process dozens of strips simultaneously.

- Advantages: High throughput for slitting wide rolls; no heat damage to natural fibers.

Laser Cutting (Specialty)

- Mechanism: High-powered lasers vaporize fibers to create a clean, sealed edge.

- Ideal For: Complex shapes or branded cuts in technical webbings.

- Throughput: Moderate—generally slower than hot-knife but superior flexibility for custom profiles.

- Advantages: Intricate cutting patterns, no physical blade wear, fine edge quality.

Machine Selection Criteria

- Production Volume: Continuous hot-knife for highest throughput; roller-fed for medium runs.

- Material Compatibility: Heat-sensitive natural fibers may require shear slitting instead of hot cutting.

- Budget & ROI: CNC systems demand higher capital investment (USD 20,000–100,000) but lower per-unit labor costs over 10,000+ meters. Roller-fed cutters start around USD 5,000.

Edge Quality & Maintenance

Maintaining blade sharpness and calibrating heat settings are crucial. Regular preventative maintenance—blade replacement, alignment checks, and controller firmware updates—ensures consistent output and minimizes downtime. Investing in service contracts can extend machine life by up to 30%.

What Is Manual Webbing Cutting and How Is It Performed?

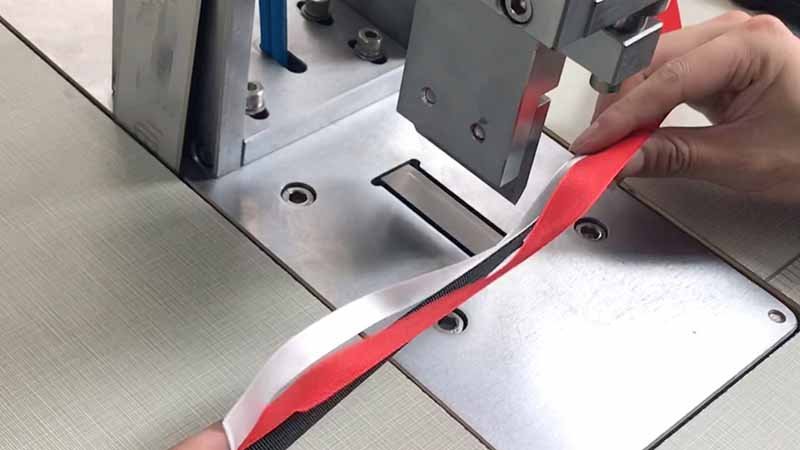

Manual webbing cutting employs hand tools—scissors, utility knives, or handheld hot cutters—to trim webbing to length. Operators mark measures, clamp or pinch the webbing, then cut. Best suited for low-volume, highly customized orders, manual cutting offers adaptability but demands skilled labor for consistency.

Manual cutting remains indispensable for small batches, prototype development, and highly customized projects where flexible adjustments outweigh throughput:

Common Tools & Techniques

- Heavy-Duty Scissors: Easy to use; produce clean cuts on thinner webbings (up to 2 mm thick).

- Utility Knives with Straightedge: Allow precise straight cuts on thicker or stiffer materials but require a stable cutting surface.

- Handheld Hot Cutters (“Hot Knife Pens”): Combine cutting and edge sealing in one handheld tool—ideal for nylon or polyester but limited to slower speeds (~1–2 meters per minute).

Step-by-Step Process

- Measurement & Marking: Use measuring tapes or digital calipers; mark cut points with chalk or adhesive markers.

- Securing Material: Clamp or tape webbing to cutting board to prevent slippage.

- Cutting Motion: Smooth, controlled strokes—scissors closed fully for scissors; straightedge guides knife.

- Edge Treatment: Trim loose fibers; for synthetics, lightly seal cut ends using a flame or hot cutter to prevent fraying.

Operator Skill & Ergonomics

- Fatigue Management: Repetitive cutting can cause wrist strain—ergonomic tools with cushioned handles and spring-loaded blades reduce force needed.

- Training: Experienced operators develop muscle memory for consistent strokes and learn to identify subtle changes in cut quality.

Use Cases & Limitations

- Ideal Scenarios: Small private-label orders (<500 pieces), prototyping, mixed-material bundles where machine setup is impractical.

- Limitations: Cut length variability ±1–2 mm, inconsistent edge sealing without hot tools, slow throughput (<50 cuts/hour per operator).

Quality Control

Implement spot checks every 20 cuts—measure lengths, inspect edges under magnification for loose fibers, and record operator averages. This feedback loop helps maintain sub-millimeter tolerances and empowers less experienced staff through immediate correction.

What Are the Key Advantages and Disadvantages of Automated Cutting?

Automated cutting shines in precision, speed, and consistency—ideal for large-scale synthetic webbing production requiring sealed edges. However, it demands significant upfront investment, regular maintenance, and specialized training, making it less cost-effective for small batches or natural-fiber materials.

Automation transforms webbing cutting from labor-intensive craftsmanship into streamlined industrial processes. Yet, it’s not a one-size-fits-all solution. Below, we critically examine its major benefits and challenges:

Advantages

- Precision & Consistency

- Repeatability: CNC controls guarantee each cut matches programmed length within ±0.1 mm—imperative for mass-market products where tolerance stacks cause assembly issues.

- Uniform Edge Sealing: Hot-knife systems instantly fuse synthetic fibers, eliminating fray and enhancing tensile strength at cut ends.

- High Throughput

- Production Speed: Continuous systems slice up to 150 m/min, reducing labor costs to <$0.02 per meter when running 8-hour shifts.

- Automation of Repetitive Tasks: Frees skilled operators to oversee multiple machines or focus on quality inspection.

- Reduced Waste & Scrap

- Optimized Nesting: Software can plan cut patterns to minimize leftover webbing.

- Automated Defect Detection: Integrated vision systems flag holes or misfeeds, stopping production before large batches are compromised.

- Scalability

- Batch Flexibility: Simple digital input changes length or pattern without mechanical retooling, facilitating rapid product variant launches.

- Integration Potential: Can link to ERP/MRP systems for real-time inventory tracking and just-in-time manufacturing.

Disadvantages

- Capital & Operational Costs

- Upfront Investment: CNC cutters range USD 20,000–100,000; laser systems can exceed USD 150,000 with safety infrastructure.

- Maintenance & Repairs: Heated blades wear out; replacement costs (USD 200–500 per blade) and specialized technicians drive ongoing expenses.

- Complex Setup & Training

- Technical Expertise: Operators require programming skills and understanding of thermal dynamics for edge sealing.

- Longer Changeover Time: Switching materials (e.g., from nylon to cotton) necessitates blade swaps and temperature recalibrations, potentially halting lines for 30+ minutes.

- Material Limitations

- Natural Fibers: Heat-based cutters can scorch or weaken cotton or hemp webbings.

- Exotic Patterns: Large-format patterned webbings may not align correctly if feed rollers don’t support printed registration marks.

- Risk of Downtime

- Mechanical Failures: Sensor misalignment or motor failures can halt entire production cells.

- Software Bugs: Firmware updates may introduce new bugs, requiring manufacturer support.

What Are the Key Advantages and Disadvantages of Manual Cutting?

Manual cutting excels in flexibility, low initial cost, and ease of use for small, custom runs. However, it suffers from slower throughput, greater variability in cut quality, and higher per-unit labor costs, making it less suitable for large-volume standardized production.

Manual webbing cutting remains vital for boutique manufacturers, prototyping labs, and applications demanding human judgment. However, adopting it exclusively in high-volume settings can introduce inefficiencies:

Advantages

- Minimal Capital Outlay

- Tool Cost: Quality scissors or handheld hot cutters cost USD 20–200, making initial investment accessible for startups.

- No Software Licensing: Eliminates recurring fees tied to CNC or vision systems.

- High Flexibility

- Rapid Changeovers: Switch between materials and lengths instantly—no machine warm-up or blade change required.

- Custom Shapes & Details: Skilled cutters can adapt on the fly for unusual angles or decorative edge treatments.

- Operator Intuition

- Visual Inspection: Real-time assessment of color patterns and weave alignment by human eye prevents miscuts on intricate webbings.

- Adaptive Corrections: Operators compensate for minor webbing roll inconsistencies or stretch without stopping production.

- Low Maintenance

- Simple Care: Sharpen or replace blades weekly; no electronics, servo motors, or heated elements to service.

- Portable Tools: Easily take operations to remote or field locations where machinery is impractical.

Disadvantages

- Inconsistent Quality

- Length Variance: Operator skill affects tolerances—expect ±1–2 mm differences without jigs or fixtures.

- Edge Finish: Hot-knife pens may not reach uniform temperature, leading to partial sealing or discoloration.

- Labor Intensity & Fatigue

- Throughput Limits: A single operator averages 30–50 cuts/hour, significantly lower than automated systems.

- Ergonomic Risks: Prolonged cutting tasks can cause repetitive strain injuries, increasing absenteeism.

- Higher Per-Unit Costs

- Labor Costs: Skilled cutters may command USD 15–25/hour—over $0.50 per cut for small lengths.

- Opportunity Cost: Allocating experienced staff to manual tasks distracts from higher-value roles like quality assurance or design iteration.

- Scaling Challenges

- Headcount Requirements: Scaling output demands proportional hiring, training, and facilities expansion.

- Quality Control Burden: More operators mean more spot checks and supervisory oversight to maintain standards.

How Do Hot Cutting and Cold Cutting Compare in Automated Processes?

Hot cutting (heat sealing) fuses synthetic webbing edges using heated blades, preventing fray and delivering smooth finishes. Cold cutting (shear slitting or crush cutting) slices natural fibers without heat, preserving material integrity but requiring additional edge-sealing steps for synthetics.

Automated cutting methods split into two broad categories—hot and cold—each optimized for specific material families and production goals. Understanding their mechanics and implications ensures you select the right process for your webbing application.

Hot Cutting (Heat Sealing)

- Mechanism & Equipment

- High-temperature blades (200–300 °C) slice and seal simultaneously.

- Pressure rollers press edges immediately after cutting, ensuring melted fibers coalesce.

- Material Suitability

- Ideal: Nylon, polyester, PP pipelines.

- Avoid: Cotton, hemp, jute—organic fibers may char or weaken.

- Edge Quality

- Outcome: Glossy, smooth edge with zero loose fibers; enhances tensile strength by up to 15%.

- Speed Trade-Off: Faster than cold methods, but speed must balance heat dwell time to prevent scorching.

- Energy & Maintenance

- Energy Use: Continuous heating draws 500–1,500 W per cutter.

- Blade Lifespan: 2,000–5,000 linear meters before edge dulling; replacement costs USD 200–500.

Cold Cutting (Shear Slitting & Crush Cutting)

- Mechanism & Equipment

- Shear Slitting: Two offset blades pass like scissors—ideal for straight, narrow cuts.

- Crush Cutting: Lower blade stationary, upper blade descends, shearing webbing against anvil.

- Material Suitability

- Ideal: Cotton, hemp, blended fibers, specialty silicones.

- Note: Synthetic webbings cut cold may fray; require post-cut sealing.

- Edge Quality

- Outcome: Soft, matte finish retaining natural fiber texture; fraying risk if left untreated.

- Secondary Process: Flame or chemical sealants may be applied downstream for synthetics.

- Operational Considerations

- Blade Maintenance: Sharpening frequency every 10,000 meters; low replacement cost (USD 50–100).

- Energy Use: Minimal—motor power 100–300 W; suitable for low-power facilities.

Comparative Table of Automated Cutting Methods

| Feature | Hot Cutting | Shear Slitting | Crush Cutting |

|---|---|---|---|

| Suitable Materials | Nylon, Polyester, PP | Cotton, Hemp, Blends | Cotton, Hemp, Blends |

| Edge Seal | Instant, FRAY-FREE | Requires secondary sealing | Requires secondary sealing |

| Throughput (m/min) | 80–150 | 50–100 per blade | 40–80 per blade |

| Blade Cost (per unit) | USD 200–500 | USD 50–100 | USD 50–100 |

| Maintenance Frequency | Every 2,000–5,000 meters | Every 10,000 meters | Every 10,000 meters |

| Energy Consumption | 500–1,500 W | 100–300 W | 100–300 W |

| Ideal Use Case | High-volume synthetic runs | Natural fiber slitting jobs | Low-volume slitting jobs |

Which Factors Should You Consider When Choosing Between Automated and Manual Cutting?

Select a cutting method based on production volume, material type, budget, and in-house expertise. High-volume synthetic orders benefit from automated hot cutting, while low-volume, mixed-material, or highly customized jobs often favor manual cutting for flexibility and lower capital commitment.

Making an informed choice requires evaluating multiple, often interrelated factors. Let’s break down the decision matrix:

- Production Volume & Batch Size

- Large-Scale Runs (10,000+ units): Automation amortizes capital costs quickly; labor costs become negligible per unit.

- Small Batches (<500 units): Manual cutting avoids machine setup fees and permits flexible length changes without downtime.

- Material Type & Fiber Composition

- Synthetic Webbing (Nylon, Polyester, PP): Hot cutting prevents fray and streamlines edge treatment.

- Natural Fibers (Cotton, Hemp, Jute): Cold methods preserve fiber strength; manual hot-knife pens handle occasional synthetic blend items.

- Budget Constraints & ROI Timeline

- Capital Availability: If budget allows USD 20k+ investment with ROI in 6–12 months, CNC automation makes sense.

- Operating Expense Focus: Manual tools (USD 20–200) and labor costs may fit tight startup budgets, deferring capital expenditure.

- In-House Expertise & Maintenance Capacity

- Technical Staff: Companies with engineers and PLC programmers can integrate automated cutters seamlessly.

- Lean Teams: Small operations benefit from plug-and-play manual tools requiring minimal technical support.

- Product Complexity & Customization Needs

- Standard Straps & Belts: Automated machines excel at uniform, repetitive tasks.

- Unique Shapes & Mixed Patterns: Manual cutting allows real-time visual alignment and creative adjustments.

- Facility Footprint & Utilities

- Space Availability: CNC or laser cutters need dedicated floor space (10–30 m²) and proper ventilation.

- Power Supply: Hot-knife machines require stable, high-wattage circuits; manual cutters demand negligible power.

- Quality Standards & Compliance

- High Precision Tolerance (±0.1 mm): Automation achieves tight specs consistently.

- Artisanal Appeal: Hand-finished edges often valued in premium or bespoke markets.

- Time to Market & Changeover Flexibility

- Rapid Iteration: Manual methods enable instant length changes without waiting for machine warm-up.

- Scheduled Production: Automated setups may take 30–60 minutes per material change, acceptable for planned batch runs.

Decision Matrix Example

| Decision Factor | Automated Cutting | Manual Cutting |

|---|---|---|

| Capital Cost | High (USD 20k–100k+) | Low (USD 20–200) |

| Labor Cost per Unit | Low (<$0.02/m) | High (>$0.50/cut) |

| Throughput | Very High (150 m/min) | Low (50 cuts/hour) |

| Tolerance | ±0.1 mm | ±1–2 mm |

| Edge Finish | FRAY-FREE, sealed | Variable; hot pens required for synthetics |

| Flexibility | Low for small runs | High |

| Maintenance Complexity | High | Low |

| Ideal Batch Size | 10,000+ units | <500 units |

What Best Practices Ensure Safety and Quality in Webbing Cutting Operations?

Implement machine guarding, enforce operator training, schedule regular blade maintenance, and institute quality-inspection protocols. Ensure consistent edge smoothness, dimensional accuracy, and safe workflows by combining visual checks, digital measurement tools, and documented SOPs.

Whether automated or manual, maintaining impeccable safety and quality standards protects both personnel and product integrity. Below are essential practices:

Safety Measures

- Machine Guarding & Emergency Stops

- Physical Barriers: Install interlocked guards around hot-knife and shear cutters to prevent accidental contact.

- E-Stop Accessibility: Clearly marked, within arm’s reach of operators; monthly functional tests.

- Operator Training & Certification

- Standardized Curriculum: Cover tool operation, material characteristics, hazard recognition, and first-aid response for burns or cuts.

- Regular Refresher Courses: Quarterly modules on new equipment, updated SOPs, and incident reviews.

- Personal Protective Equipment (PPE)

- Gloves: Cut-resistant gloves rated ANSI A3 for manual cutting.

- Eye Protection: Safety glasses or face shields to guard against blade fragments and hot-knife splatter.

- Heat-Resistant Apparel: For hot-knife operators; flame-retardant sleeves or aprons.

- Ergonomic Workstations

- Adjustable Benches: Height-adjustable tables reduce bending and wrist strain.

- Anti-Fatigue Mats: Minimize leg discomfort during prolonged standing.

Quality Assurance Protocols

- Blade & Cutter Maintenance

- Preventative Schedules: Log every 5,000 meters for hot-knife blades; 10,000 for shear blades.

- Calibration Checks: Monthly verification of length accuracy using certified gauge bars.

- Digital Monitoring & Traceability

- Cut Counters & Logs: Automatic recording of lengths, batch numbers, and blade usage hours.

- Vision Inspection: Automated cameras detect frayed edges or length deviations beyond tolerance.

- Sampling & Statistical Process Control (SPC)

- Random Spot Checks: Inspect 5% of each batch—measure length, weigh straps, examine edges.

- Control Charts: Track key metrics (mean length, standard deviation); trigger corrective action if out of control.

- Documented Standard Operating Procedures (SOPs)

- Step-By-Step Guides: Visual SOPs posted at each station for tool setup, cutting technique, and emergency protocols.

- Change Management: Formal process when updating equipment or materials—train staff, revise SOPs, and validate performance.

- Continuous Improvement Loop

- Root Cause Analysis: Investigate any defect above 2% rate; implement countermeasures like blade adjustments or retraining.

- Operator Feedback: Monthly meetings to gather insights and suggestions for process enhancements.

How Can You Optimize Cutting Processes for Efficiency and Cost-Effectiveness?

Optimize by integrating nesting software, balancing manual and automated tasks, and leveraging production data for downtime analysis. Schedule preventive maintenance, standardize changeover procedures, and train cross-functional teams to ensure continuous improvement and cost reduction in webbing cutting.

Achieving peak performance in webbing cutting isn’t a one-off task—it demands ongoing refinement. Here’s how top manufacturers fine-tune operations:

- Workflow Integration & Nesting

- Material Utilization Software: Use algorithms to nest multiple strap lengths on wider-roll webbing, reducing scrap by up to 15%.

- Batch Scheduling: Group similar materials and lengths together to minimize setup changes.

- Blending Automation with Manual Touchpoints

- Hybrid Lines: Pre-cut lengths automatically, then finish with manual detail work (edge treatments, decorative stitching) for custom orders.

- Flexible Cells: Equip cells with both CNC cutters and handheld hot knives—operators switch based on immediate demand.

- Preventive Maintenance & Downtime Reduction

- Condition-Based Monitoring: Install vibration and temperature sensors on motors to predict failures before they occur.

- Spare Parts Inventory: Maintain critical spares (blades, belts, sensors) on-site to cut repair lead times by 50%.

- Data-Driven Decision Making

- Downtime Analysis: Log every stoppage—classify causes (blade change, material jam, calibration) and target top three for elimination.

- Productivity Metrics: Track throughput per operator or per machine; benchmark against industry standards (e.g., 100 m/hour for small-batch lines).

- Lean Principles & 5S Implementation

- Sort & Set in Order: Keep tools, blades, and gauges organized at point of use to reduce search time.

- Shine: Establish daily cleaning rituals to spot wear early.

- Standardize & Sustain: Document best practices and audit compliance monthly.

- Cross-Training & Skill Development

- Multi-Skill Teams: Train cutting operators in machine maintenance basics and quality inspection, enabling rapid response to issues.

- Continuous Learning: Host quarterly “tech days” where vendors introduce new cutting technologies or materials.

Conclusion

Balancing the strengths of automated and manual webbing cutting unlocks both efficiency and craftsmanship. High-volume synthetic strap production thrives on precision hot-knife systems, while small-batch, bespoke orders benefit from the adaptability of skilled manual cutters. By weighing factors like volume, material, budget, and technical capacity—and embracing best practices in safety, maintenance, and continuous improvement—you’ll achieve top-tier quality and cost control.

Ready to elevate your webbing products? Contact Szoneier today for custom solutions, from advanced CNC cutting to artisanal manual trimming. Our 18+ years of R&D, free design, low MOQ, fast sampling, and 100% quality guarantee ensure your next project exceeds expectations. Request a quote now and discover why leading brands trust Szoneier for premium webbing manufacturing.