Securing cargo has never been more critical. Whether you’re hauling heavy equipment across state lines or tying down gear for a weekend camping trip, the right tie down strap can mean the difference between a successful journey and a dangerous disaster. With advances in materials and hardware design, the tie down straps of 2025 offer unprecedented strength, durability, and ease of use. From elastic bungee alternatives to heavy-duty ratchet straps, choosing the wrong strap could cost you time, money, or even lives.

The best tie down straps of 2025 combine high working load limits (up to 5,000 lb), UV-resistant polyester or nylon webbing, corrosion-proof hardware, and user-friendly mechanisms like ratchets or cam buckles. Top types include ratchet straps for maximum tension, cam buckle straps for light loads, soft-loop straps for delicate surfaces, E-Track/A-Track systems for trailers, and specialty winch or over-the-top straps for unique applications.

Imagine you’re a small-business fleet manager who’s just lost a valuable generator because your old cam straps gave way in the rain. That nightmare becomes a thing of the past when you arm yourself with the perfect 2025-era tie down solution. Let’s dive into the five most critical strap types—and how to pick the one that keeps your cargo exactly where it belongs.

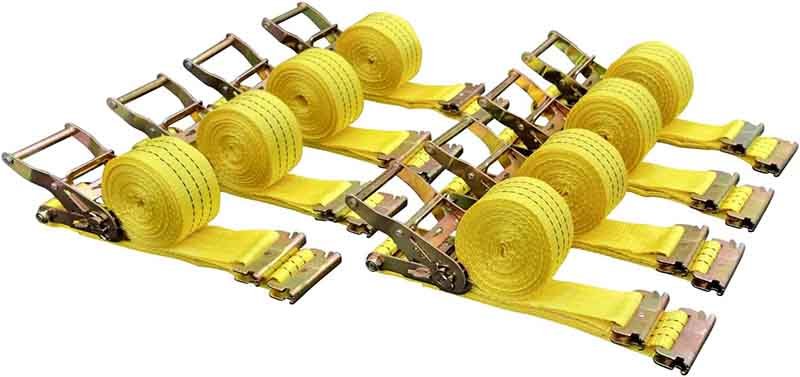

Ratchet Tie Down Straps – Maximum Tension and Security

Ratchet tie down straps deliver the highest tension, offering working load limits from 1,500 lb to over 5,000 lb. Their ratcheting mechanism allows precise tension control, making them ideal for heavy equipment, machinery, and commercial hauling where slip-resistance and security are non-negotiable.

Ratchet straps remain the gold standard for heavy-duty securing. At the core of these systems is a simple yet effective mechanical advantage: the ratchet mechanism. By feeding the strap through the ratchet’s spindle and squeezing the handle, users can incrementally tighten the webbing until the desired tension is achieved. This ensures that heavy loads—such as loaders, generators, and construction materials—stay immobile during transport.

1. Webbing Materials and Strength:

Modern ratchet straps typically use UV-resistant polyester, known for its low stretch (around 8–12%) under load, excellent abrasion resistance, and colorfastness in sunlight. Some high-end models incorporate blended nylon for additional elasticity (up to 18%), which can absorb shock loads during transit. Working load limits (WLL) range from 1,500 lb for light-duty consumer straps up to 5,000 lb or more for professional-grade gear.

2. Hardware Quality:

Zinc-plated or powder-coated steel ratchets resist corrosion, even when exposed to salt spray or rain. Stainless-steel hardware is available for marine or harsh-environment use. Look for safety certifications such as DOT/FMCSA compliance in the U.S., ensuring straps meet regulated minimum performance thresholds.

3. Operation and Safety:

Proper threading is crucial: weave the strap through the ratchet drum in the correct direction to avoid jams. Over-tightening can damage webbing fibers—stop ratcheting when you feel firm resistance. Always inspect straps before use: any fraying, cuts deeper than 10% of the webbing width, or rust on hardware warrants replacement.

4. Typical Applications:

- Heavy machinery transport

- Commercial flatbed trucking

- Agricultural equipment hauling

- Industrial pallet securing

5. Pros & Cons:

| Pros | Cons |

|---|---|

| Highest tension and minimal slip | Heavier and bulkier than cam straps |

| Precise tension control | Learning curve for proper thread routing |

| Wide WLL range (1,500 – 5,000+ lb) | More expensive than lighter-duty options |

With ratchet straps, you invest in ultimate security. If your priority is keeping heavy loads immovable under extreme conditions, these are the straps to trust.

Cam Buckle Straps – Easy Adjustment for Light Loads

Cam buckle straps offer quick, tool-free tensioning for loads up to 1,000 lb. Their spring-loaded cam mechanism grips the webbing once tensioned, making them perfect for securing lighter cargo like furniture, kayaks, or luggage without the bulk of a ratchet system.

Cam buckle straps shine when ease-of-use and speed matter more than maximum tension. The cam mechanism features a simple spring-loaded lever: as you pull the webbing through, the cam’s serrated teeth engage, holding the strap under tension without the need for ratcheting.

1. Webbing and Material Behavior:

Typically made from polyester or polypropylene (PP) webbing, cam buckle straps exhibit slightly higher stretch (10–15%) compared to ratchet straps. This elasticity can help cushion slight shifts in load during transport. Polyester versions resist UV degradation better than PP, while PP models are lighter and more cost-effective.

2. Operation & Speed:

Securing cargo takes seconds: hook both ends, pull the loose webbing through the cam, and let the built-in teeth lock in place. Releasing is just as easy—flip the cam lever and slide the webbing free. No cranking, no tools, no fuss.

3. Load Limitations:

Cam buckle straps generally have working load limits between 200 lb (for ultra-light variants) up to 1,000 lb for larger models. This makes them unsuitable for heavy machinery but ideal for moderate loads like bicycle racks, rooftop cargo carriers, or securing boxes in a moving van.

4. Durability & Maintenance:

With fewer moving parts than ratchets, cams are less prone to mechanical failure. However, the spring-loaded mechanism can wear over time. Always check that the cam teeth remain sharp and the spring retains tension. Webbing should be inspected for fraying, UV damage, or loose stitching.

5. Use Cases:

- Furniture moving

- Outdoor gear (tents, kayaks)

- Residential moving trucks

- Event staging equipment

Cam buckle straps empower DIYers and occasional shippers to secure loads swiftly and without specialized training. When your cargo is moderate in weight and you value speed, these straps are the way to go.

Soft-Loop Tie Down Straps – Protecting Delicate Surfaces

Soft-loop tie down straps feature textile loops instead of metal hooks, reducing surface damage on painted or finished objects. With working load limits from 500 lb to 2,000 lb, they’re perfect for securing motorcycles, antiques, or fine furniture where aesthetics matter.

When hauling high-value or delicate cargo—like custom motorcycles, classic cars, or fine art—metal hooks can scratch, dent, or mar the finish. Soft-loop straps solve this by replacing rigid hardware with heavy-duty textile loops that wrap around anchor points without direct metal-to-surface contact.

1. Construction & Strength:

These straps use the same high-strength webbing found in ratchet systems, often UV-resistant polyester rated for WLLs between 500 lb and 2,000 lb. The textile loops are double-stitched with industrial-grade thread and reinforced with bar-tack stitches to prevent slippage.

2. Compatible Hardware:

Soft loops slip over anchor points—like D-rings, rails, or coil hooks—then ratchet or cam buckles thread through the loop. This hybrid approach offers the protection of soft contact with the controlled tension of ratchet or cam systems.

3. Surface Protection & Versatility:

- Motorcycles: Wrap loops around triple-tree forks to avoid scratching fork legs.

- Antiques & Furniture: Secure delicate legs or rails without metal hooks biting into wood or paint.

- Automotive: Protect bumpers and rails when transporting show cars.

4. Inspection & Care:

Soft-loop fabric can wear from abrasive anchor points. Inspect for thread abrasion, UV fading, or chemical damage. Machine wash mild, air-dry away from direct sunlight. Do not bleach.

5. Pros & Cons:

| Pros | Cons |

|---|---|

| Eliminates metal-to-surface damage | Slightly more expensive than basic straps |

| Maintains high WLL (500 – 2,000 lb) | Loop strength depends on proper stitching |

| Compatible with various buckles and hooks | Not ideal for extremely heavy payloads (>2,000 lb) |

For anyone transporting items where aesthetics and surface integrity matter, soft-loop straps offer the best of both worlds: protection and strength.

E-Track and A-Track Straps – Versatile Trailer Solutions

E-Track and A-Track systems integrate with recessed rails in trailers, vans, or trucks, offering infinite anchor points for straps. Straps with specialized fittings lock directly into tracks, delivering secure, adjustable tie-down for loads ranging from 500 lb to 5,000 lb.

Cargo trailers and walk-in vans often feature E-Track (horizontal) or A-Track (vertical) recessed rails. These standardized rails accept fittings that slide and lock into position, allowing complete flexibility in tie down placement.

1. System Overview:

- E-Track Rails: Installed horizontally along walls or floors, spaced at 24 inches or 36 inches.

- A-Track Rails: Vertical orientation, offering higher strength per anchor point.

Specialty straps terminate in E-Track fittings—a U-shaped metal bracket with spring-loaded locking pins. Sliding the fitting into a rail slot and twisting or toggling the spring lock secures the strap at any point along the rail.

2. Load Capacity & Configuration:

E-Track fittings generally support WLLs of 1,000 lb to 5,000 lb, depending on material and rail thickness. Multiple straps can be used in tandem for larger items. Rails themselves are rated (e.g., 5,000 lb per fitting with distributed load), ensuring system integrity.

3. Installation & Use:

- Mounting Rails: Secure rails to structural studs or floor joists with appropriate fasteners.

- Adjusting Anchor Points: Slide fittings to the desired slot; twist or press to lock.

- Tensioning: Use ratchet or cam buckles on webbing to cinch loads.

4. Applications:

- Furniture delivery vans

- Moving trucks

- Utility trailers

- Mobile workshops

5. Pros & Cons:

| Pros | Cons |

|---|---|

| Infinite, adjustable anchor points | Requires pre-installed rails |

| High WLL when combined with ratchet straps | Installation adds cost and complexity |

| Clean, flush mounting preserves cargo space | Rails can be damaged if overloaded improperly |

For professionals who require a configurable and scalable tie-down solution inside trailers or vans, E-Track and A-Track systems paired with compatible straps deliver unmatched versatility.

Bungee and Shock Cords – Quick and Flexible Securing

Bungee cords and shock-cord straps use elastic webbing to absorb impact and adjust quickly to varying loads. Rated for lighter cargo (100 – 300 lb), they excel at temporary or quick-release applications like securing tarps, small gear, or market displays.

Elastic tie downs—commonly known as bungee cords—offer unmatched convenience for light, irregularly shaped, or frequently accessed loads. Made of rubber or thermoplastic elastomer cores wrapped in woven polyester sleeves, they stretch 50–200% of their resting length.

1. Stretch & Shock Absorption:

The elasticity absorbs jolts from road irregularities, reducing load shifting. However, shock cords should not replace webbing straps for heavy or safety-critical loads, as they lack precise tension control and have lower WLLs (100–300 lb).

2. Hook Styles & Safety:

Metal S-hooks are popular but can be sharp; coated or plastic hooks minimize damage. Always choose cords with end-cap protectors to prevent hooks from slipping off anchor points. Inspect for cracked hooks or frayed sleeves before each use.

3. Use Cases:

- Tarps over ATV or motorcycle trailers

- Securing market stall banners

- Bundling hoses, cables, or lightweight gear

- Temporary cargo holds on pickups

4. Pros & Cons:

| Pros | Cons |

|---|---|

| Instant application—no threading or ratcheting | Low WLL unsuitable for heavy loads |

| Elasticity absorbs road shock | Hooks can fail or slip under tension |

| Compact and easy to store | UV and ozone degrade rubber over time |

While bungee cords and shock-cord straps shine in quick-fix scenarios, never rely on them for safety-critical or heavy-duty securing tasks.

Specialty Straps – Winch Straps, Over-the-Top Straps, and More

Specialty tie down straps—including winch straps, over-the-top straps, and extension straps—address unique challenges like angled loads, high-rise stacks, or integrated winch systems. Working load limits vary from 1,000 lb to 10,000 lb depending on design.

Certain hauling scenarios fall outside standard ratchet or cam strap capabilities. Specialty straps fill these niches with bespoke designs:

1. Winch Straps:

- Design: Heavy-duty polyester webbing (2″–3″ wide) with welded loops for winch drum attachment.

- Function: Replace steel cable on electric or hydraulic winches, offering silent, corrosion-resistant pulling.

- WLL: 5,000 – 10,000 lb depending on webbing grade.

- Usage: Off-road vehicle recovery, industrial winching, marine salvage.

2. Over-the-Top Straps:

- Design: Extra-long webbing with loops or hooks at both ends, draped over tall loads (e.g., stacked logs or pipes).

- Function: Secure loads that exceed the height of anchor points by creating an over-the-top anchor.

- WLL: 2,000 – 6,000 lb.

- Usage: Timber hauling, steel pipe transport, scaffolding movement.

3. Extension and Connector Straps:

- Design: Short link straps used to join multiple straps or extend reach.

- Function: Offer modular flexibility in complex tie-down configurations.

- WLL: Matches parent strap (1,500 – 5,000 lb).

- Usage: Multi-point anchoring, custom trailer builds.

4. Pros & Cons:

| Strap Type | Specialty | WLL Range |

|---|---|---|

| Winch Straps | Silent, corrosion-resistant cable alternative | 5,000 – 10,000 lb |

| Over-the-Top Straps | Securing tall/awkward loads | 2,000 – 6,000 lb |

| Extension Straps | Modular linkage | 1,500 – 5,000 lb |

Specialty straps provide targeted solutions when standard straps fall short. By matching the right specialty design to your application, you gain both safety and efficiency in challenging load scenarios.

How to Choose the Right Tie Down Strap for Your Needs

Selecting the right tie down strap involves matching load weight, anchor style, and environmental conditions to strap material, width, and hardware. Prioritize working load limit (WLL), webbing material (polyester vs. nylon), buckle type, and certifications to ensure safety and longevity.

Choosing the perfect tie down strap can feel overwhelming given the myriad options. Here’s a systematic approach:

1. Determine Load Characteristics:

- Weight & Dimensions: Sum the weight of all items. For multiple straps, ensure total WLL exceeds 2× the load weight for redundancy.

- Shape & Fragility: Use soft-loop straps for delicate finishes, over-the-top for tall stacks.

2. Select Material Based on Environment:

- Polyester Webbing: Low stretch, UV resistance — ideal for constant sunlight exposure.

- Nylon Webbing: Higher stretch, superior shock absorption — good for dynamic loads but avoid moisture-prone conditions (nylon absorbs water).

- Polypropylene (PP): Most cost-effective, lightweight, but lower UV and abrasion resistance.

3. Choose Buckle or Mechanism:

| Mechanism | WLL Range | Ease of Use | Ideal For |

|---|---|---|---|

| Ratchet | 1,500 – 5,000 lb | Precise tensioning | Heavy machinery, commercial |

| Cam Buckle | 200 – 1,000 lb | Quick adjust/release | Light to medium loads |

| Soft-Loop + Ratchet | 500 – 2,000 lb | Surface protection | Motorcycles, antiques |

4. Inspect Certifications & Testing:

- DOT/FMCSA Compliance: U.S. regulatory standards for commercial transport.

- ISO Certification: Global standards for manufacturing consistency.

5. Factor in Accessories & Storage:

Invest in strap racks, edge protectors, and protective sleeves to prolong strap life. Proper storage off the ground and out of UV exposure adds years to your gear.

By following this decision matrix, you ensure that each strap you purchase is right-sized, right-rated, and right-designed for your unique load.

Best Practices and Common Mistakes to Avoid

Avoid twisting webbing, over-tensioning, and misrouting around sharp edges. Always inspect straps for cuts, abrasion, or hardware corrosion before use. Use edge protectors and distribute load evenly to maximize strap lifespan and cargo safety.

Even the best tie down straps fail if used improperly. Here’s how to stay safe:

1. Proper Threading & Routing:

- Ensure webbing lies flat—no twists or folds.

- Route straps away from sharp corners; use edge protectors when unavoidable.

- For E-Track systems, confirm fittings fully engage the rail before tensioning.

2. Tensioning Techniques:

- Ratchet straps: Stop when resistance is firm but not crushing. Over-cranking can weaken fibers.

- Cam buckles: Pull firmly but avoid jerking motions that can pop the cam open.

- Shock cords: Only stretch to 75–90% of max length to avoid hook slippage.

3. Regular Inspection:

- Before Each Use: Look for frayed edges, deep cuts (>10% of width), UV brittleness, and corroded hardware.

- Periodic Maintenance: Clean webbing with mild soap and water; lubricate ratchet gears annually.

4. Storage & Care:

- Store in a cool, dry place away from direct sunlight.

- Hang straps or coil loosely—avoid tight knots that create permanent creases.

- Keep straps away from chemicals like acids or solvents that degrade polyester and nylon.

5. Real-World Cautionary Tale:

A logistics company once suffered a $20,000 loss when poorly threaded straps on a flatbed allowed steel beams to shift off during transit. Their subsequent overhaul of tie down protocols—proper training, regular inspections, and upgraded ratchet systems—eliminated cargo slippage incidents altogether.

By integrating these best practices into your operations, you’ll not only extend the life of your straps but also safeguard your cargo, reputation, and bottom line.

Conclusion

From heavy-duty ratchets to quick-release bungees, 2025 offers a tie down solution for every hauling challenge. By understanding load requirements, material properties, and proper usage techniques, you can select straps that combine reliability, ease of use, and long-term value.

Ready to upgrade your fleet’s tie down arsenal? Contact Szoneier today for custom webbing solutions tailored to your exact specifications—whether you need 100 pieces or 100,000, we deliver premium-quality straps with low MOQs, fast sampling, free design, and on-time delivery. Reach out at info@szoneierwebbing.com or visit www.szoneierwebbing.com to request a quote and secure your cargo like a pro.