In the world of cargo securing, the right choice of tie down webbing material can mean the difference between a safe delivery and a costly disaster. Whether you’re hauling heavy machinery, securing outdoor gear, or shipping delicate components, your webbing must balance tensile strength, abrasion resistance, UV stability, and flexibility—all while fitting within budget constraints. Choosing poorly can lead to frayed straps, lost loads, and reputational damage.

The best tie down webbing material depends on your application: nylon offers high strength and stretch, polyester excels in UV and abrasion resistance, PP is lightweight and cost-effective, and cotton suits light-duty, eco-friendly needs. Each has distinct load ratings and environmental tolerances.

But which fabric truly reigns supreme? Picture this: a logistics manager preparing a cross-country freight shipment discovers upon delivery that the straps have degraded from sun exposure—resulting in a delayed deadline and extra costs. Or imagine an outdoor adventure enthusiast whose overloaded roof rack strap snaps mid-trip, stranding them miles from civilization. These real-world scenarios highlight why a critical, data-driven approach to selecting tie down webbing is essential. In the following sections, we’ll unpack commonly used materials, compare performance metrics, review coatings and treatments, explore eco-friendly options, and guide you toward the ideal webbing for your precise needs. Let’s dive deeper and secure your cargo with confidence.

What Types of Materials Are Commonly Used for Tie Down Webbing?

Tie down webbing commonly utilizes nylon, polyester, polypropylene (PP), and cotton. Nylon is prized for strength and elasticity, polyester for UV and abrasion resistance, PP for cost-effectiveness and light weight, and cotton for gentle handling and biodegradability.

When selecting tie down webbing, understanding each base material’s intrinsic properties is the first step to matching performance to application. Here’s a closer look:

Nylon Webbing

- Molecular Structure & Strength: Nylon (polyamide) features strong hydrogen bonds between polymer chains, granting a tensile strength typically in the 7,000–10,000 lbf/in (31–45 kN) range for 2″ straps.

- Elasticity & Shock Absorption: With up to 30% elongation at break, nylon can absorb dynamic loads—ideal for sudden jolts in transit.

- Moisture Behavior: Nylon absorbs about 4%–6% of its weight in water, which can reduce strength by up to 10% when wet.

Polyester Webbing

- UV & Weather Resistance: Polyester (PET) resists UV degradation far better than nylon, maintaining over 90% of original tensile strength after 1,000 hours of ASTM G154 exposure.

- Dimensional Stability: With elongation under 10%, polyester offers minimal stretch—excellent for static loads where movement must be limited.

Polypropylene (PP) Webbing

- Cost & Weight Advantages: PP is typically 20–30% lighter than PET or nylon at the same width, and costs up to 40% less—making it a budget-friendly option for light to medium loads.

- Chemical Resistance: PP is inherently resistant to acids, alkalis, and many solvents, but can become brittle below –10 °C.

Cotton Webbing

- Eco-Friendly & Gentle Grip: Natural cotton is biodegradable and offers a soft hand, protecting delicate surfaces from scratches.

- Load Limitations: With tensile strength around 1,500–2,000 lbf/in (6–9 kN), cotton suits lighter applications such as bundling textiles or garden use.

| Material | Tensile Strength (2″ Strip) | Elongation @ Break | UV Resistance | Cost | Typical Use Cases |

|---|---|---|---|---|---|

| Nylon | 7,000–10,000 lbf (31–45 kN) | 20–30% | Moderate (∆10%) | Medium | Heavy cargo, dynamic loads |

| Polyester | 6,000–8,000 lbf (27–36 kN) | 8–15% | Excellent (∆5%) | Medium | Static loads, outdoor, marine |

| Polypropylene | 4,000–6,000 lbf (18–27 kN) | 10–15% | Fair (∆15%) | Low | Light-to-medium loads, cost-sensitive |

| Cotton | 1,500–2,000 lbf (6–9 kN) | 5–10% | Poor (∆25%) | Medium | General bundling, eco-friendly scenarios |

Critically, no single material is best for all scenarios. The key is evaluating your load type—static vs. dynamic—environmental exposure, budget, and any regulations (e.g., DOT requirements for transportation). In the following sections, we will scrutinize nylon vs. polyester, UV and abrasion resistance, load capacities, treatments, and more, equipping you with the insights to make an informed, data-backed decision.

How Does Nylon Compare to Polyester in Strength and Durability?

Nylon typically offers 10–20% higher tensile strength and greater elasticity than polyester, while polyester exhibits superior UV stability and lower moisture absorption—making nylon better for high-impact loads and polyester ideal for prolonged outdoor exposure.

When evaluating nylon and polyester side by side, it’s crucial to consider both mechanical performance and environmental resilience. These factors will determine which material aligns with your specific tie down requirements.

Mechanical Performance

- Tensile Strength

- Nylon: Average tensile strengths for 2″ nylon webbing range from 7,500 lbf (33 kN) to 10,000 lbf (45 kN).

- Polyester: Comparable polyester webbing usually rates between 6,000 lbf (27 kN) and 8,000 lbf (36 kN).

- Implication: If maximum load capacity is the priority—such as securing heavy industrial equipment—nylon’s higher peak strength offers a safety margin.

- Elongation & Shock Absorption

- Nylon Stretch: With up to 30% elongation at break, nylon can absorb sudden loads or shock forces, reducing stress on other cargo components.

- Polyester Stretch: Polyester elongates about 8–15%, keeping loads more dimensional stable under tension, which is critical for precision-sensitive freight (e.g., electronics).

- Tear Resistance & Fatigue Life

- Nylon: Reinforced inter-fiber bonds confer excellent resistance to repeated flexing but can develop micro-cracks if exposed to sunlight without UV treatment.

- Polyester: Slightly lower flexibility is compensated by an ability to endure tighter bending radii without permanent deformation.

Environmental Resilience

- UV Exposure

- Nylon Degradation: Untreated nylon may lose up to 30% of its tensile strength after 1,000 hours of direct UV exposure (ASTM G154).

- Polyester Lifespan: Polyester retains over 90% strength after the same exposure period, making it preferable for long-term outdoor or marine use.

- Moisture & Chemical Resistance

- Nylon Water Absorption: Nylon absorbs moisture, leading to a temporary strength loss of up to 10% when wet. Over time, repeated moisture cycles can accelerate degradation.

- Polyester Hydrophobicity: Polyester absorbs <0.4% water by weight, sustaining consistent strength and resisting mildew, mold, and most chemicals.

- Temperature Tolerance

- Nylon: Optimal operating range is –40 °F to 185 °F (–40 °C to 85 °C). Extended UV and moisture exposure can hasten aging at temperature extremes.

- Polyester: Performs well from –50 °F to 200 °F (–45 °C to 95 °C), with minimal brittleness at low temperatures.

Cost & Lifecycle Considerations

- Initial Cost: Nylon and polyester webbing are similarly priced at medium tiers, but treatments (e.g., UV inhibitors, anti-fungal coatings) can add 10–20% to the cost.

- Total Cost of Ownership: Polyester’s longer lifespan outdoors often offsets its slightly lower initial strength rating, reducing replacement frequency and maintenance in exterior environments.

Data Comparison Table

| Property | Nylon | Polyester |

|---|---|---|

| Tensile Strength | 7,500–10,000 lbf | 6,000–8,000 lbf |

| Elongation @ Break | 20–30% | 8–15% |

| UV Strength Retention | ~70% @ 1,000 hrs | ~90% @ 1,000 hrs |

| Water Absorption | 4–6% weight gain | <0.4% weight gain |

| Temperature Range | –40 °F to 185 °F | –50 °F to 200 °F |

| Price Tier | Medium | Medium |

| Typical Replacement Cycle | 2–3 years (outdoors) | 3–5 years (outdoors) |

In summary, choose nylon when shock absorption, dynamic loads, and peak tensile strength are paramount—such as in crane slings or vehicle recovery straps. Conversely, choose polyester for long-term outdoor exposure, UV resistance, and minimal stretch—ideal for rooftop cargo, marine applications, or static tie-downs. For projects requiring both sets of qualities, consider hybrid constructions or dual-layer webbing that combines a nylon core with a polyester jacket.

Which Webbing Materials Offer Superior UV and Abrasion Resistance?

Polyester and high-density polyethylene (HDPE) webbings provide the best UV resistance, retaining over 90% strength after extensive sun exposure. For abrasion resistance, solution-dyed polyester and heavy-weave nylon excel in high-friction environments.

Outdoor applications—whether on flatbed trailers, rooftop racks, or marine vessels—expose tie down webbing to relentless UV radiation and abrasive surfaces. Understanding which materials and construction methods deliver optimal longevity can save thousands in replacements and downtime.

UV Resistance

- Solution-Dyed Polyester

- Process: Pigments are added to polymer melt before extrusion, ensuring UV stability throughout the fiber cross-section.

- Longevity: ASTM G154 tests show <10% tensile loss after 2,000 hours continuous UV, translating to 5+ years of service in direct sunlight.

- Cost Impact: Solution-dyed polyester costs about 15–20% more than standard PET but doubles expected lifespan outdoors.

- High-Density Polyethylene (HDPE)

- Fiber Properties: HDPE fibers (e.g., Dyneema®) offer UV performance rivaling solution-dyed polyester, with the added benefit of exceptional creep resistance under tension.

- Applications: Specialized recovery and marine ropes often use HDPE to combine minimal stretch (<5%) with high UV endurance.

- UV-Treated Nylon

- Additives & Coatings: UV inhibitors such as Hindered Amine Light Stabilizers (HALS) can reduce nylon’s UV degradation by 50–70%, but may require periodic retreatment.

- Trade-Off: Treated nylon still absorbs moisture and remains prone to hydrolysis over long exposures.

Abrasion Resistance

- Heavy-Weave Nylon (6,6 vs. 6,12)

- Nylon 6,6 vs. 6,12: Nylon 6,6 has a tighter molecular structure, offering up to 25% higher abrasion resistance than Nylon 6,12.

- Denier & Pick Count: Higher denier yarns (1,000 denier+) and increased weft x warp pick counts (>60 x 60 per inch) slow wear when rubbing against cargo or anchor points.

- Reinforced Construction

- Double-Layer Webbing: Integrates a protective, ultra-high-molecular-weight polyethylene (UHMWPE) overlay on a nylon core, combining tensile strength with a sacrificial abrasion layer.

- Rip-Stop Weaves: Alternating thicker yarns in a grid pattern prevent small tears from propagating.

Testing & Standards

- ASTM D4151—Abrasion Resistance: Measures mass loss after 1,000 rub cycles on a standardized metal platen.

- ISO 4920—Color Fastness to Light: Assesses UV-induced fading and strength loss over controlled sunlight exposure.

- FAR 25.853—Flammability for Aerospace: Relevant for aircraft restraint webbings, requiring limited flame spread.

| Feature | Polyester (Solution-Dyed) | HDPE (UHMWPE) | Nylon 6,6 (UV-Treated) |

|---|---|---|---|

| UV Tensile Retention | ≥90% @ 2,000 hrs | ≥95% @ 2,000 hrs | 65–80% @ 1,000 hrs |

| Abrasion Mass Loss | <5% after 1,000 cycles | <3% after 1,000 cycles | <10% after 1,000 cycles |

| Stretch under Load | 8–12% | <5% | 20–30% |

| Typical Uses | Outdoor straps, awnings | Marine ropes, rescue | Heavy-duty slings |

| Price Premium vs. PET | +15–20% | +200–300% | +10–15% |

Best Practices

- Match Testing to Environment: Use ASTM or ISO protocols that mimic your actual exposure—e.g., salt spray for marine, dust abrasion for construction.

- Inspect Periodically: Even high-performance webbings should undergo visual and hands-on checks every 3–6 months in harsh climates.

- Choose Hybrid Solutions: For critical loads, consider composite webbings—nylon cores for strength, polyester jackets for UV/abrasion protection.

By aligning material properties with environmental demands—and leveraging advanced treatments or hybrid constructions—you can dramatically extend webbing service life and maintain safety margins under the harshest conditions.

What Are the Load Capacity Differences Between Various Webbing Fabrics?

Nylon webbings generally offer the highest working load limits (WLL) of 2,500–5,000 lbf, polyester ranges from 2,000–4,000 lbf, PP from 1,000–2,500 lbf, and cotton from 500–1,000 lbf. WLL depends on width, weave, and safety factors.

Calculating and comparing working load limits (WLL) across different webbing materials involves more than just base tensile strength; you must incorporate safety factors, width, thickness, and construction techniques.

Fundamental Definitions

- Tensile Strength (TS): The maximum force before failure, typically determined by ASTM D4885.

- Working Load Limit (WLL): The maximum safe load—calculated as TS ÷ Safety Factor. Industry standard safety factors range from 3:1 (for non-critical applications) to 7:1 (for life-safety or overhead lifting).

Comparative Load Tables

Assuming a safety factor of 5:1, here’s how 2″-wide webbings often compare:

| Material | TS (lbf) | Safety Factor | WLL (lbf) | WLL (kg) |

|---|---|---|---|---|

| Nylon | 10,000 | 5 | 2,000 | 907 |

| Polyester | 8,000 | 5 | 1,600 | 726 |

| Polypropylene | 6,000 | 5 | 1,200 | 544 |

| Cotton | 2,000 | 5 | 400 | 181 |

For higher-strength variants, such as 3″ nylon (12,000 lbf TS) or heavy-weave polyester (10,000 lbf TS), WLL scales accordingly. Always verify manufacturer data for exact values.

Factors Affecting Load Capacity

- Width & Thickness: Wider and thicker webbings distribute load across more fibers, increasing TS.

- Weave Density: Higher pick densities yield improved load distribution and tear resistance.

- Edge Construction: Heat-sealed or bound edges resist fraying, preserving full WLL over time.

- Temperature & Chemicals: Extreme environments can reduce WLL by up to 20%. Adjust safety factors accordingly.

Real-World Application Examples

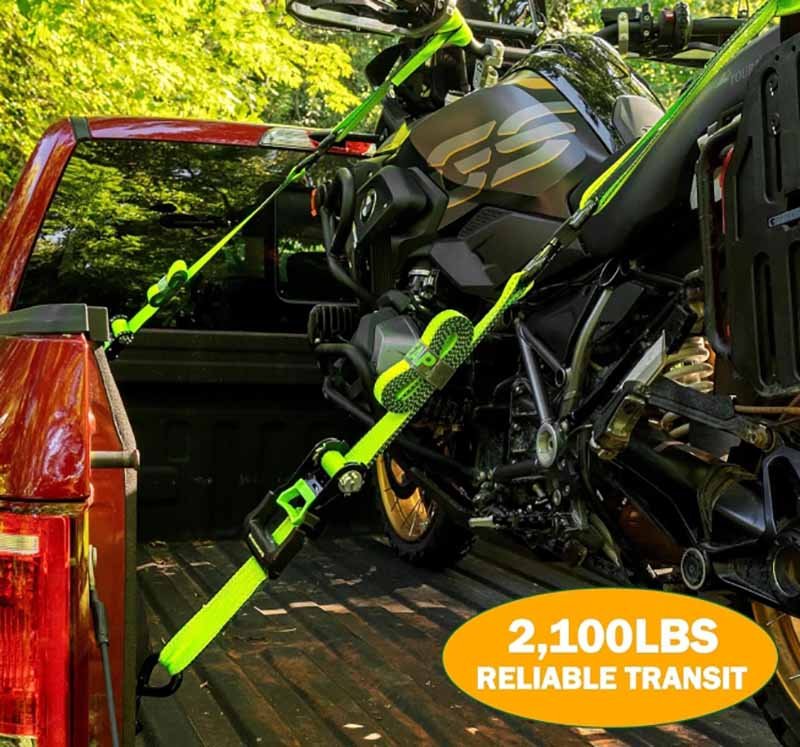

- Vehicle Recovery: A 3″ nylon strap with 12,000 lbf TS and 5:1 safety yields a 2,400 lbf WLL—sufficient for most SUVs and light trucks.

- Flatbed Securing: Two 2″ polyester straps (1,600 lbf WLL each) can safely secure a 3,000 lbf load when used with proper tensioning and edge protectors.

- Industrial Lifting Slings: Both polyester and nylon slings used in overhead lifting often employ safety factors up to 7:1, reducing WLL but ensuring a larger safety margin.

Verification & Compliance

- DOT CFR 393.100–106: U.S. regulations requiring marked WLL on cargo securement devices.

- EN 12195-2 (Europe): Specifies WLL calculation and testing standards for lashing straps.

By analyzing WLL values in context—width, safety factor, environment—you can accurately specify the correct webbing for your load. Overestimating capacity risks failure; underestimating can lead to over-engineering and unnecessary cost.

How Do Coatings and Treatments Enhance Webbing Performance?

UV stabilizers, anti-fungal/anti-mold treatments, water-repellent coatings, and flame-retardant finishes can extend webbing life by 30–50%, reduce moisture uptake, and meet specialized safety standards like NFPA 701.

Beyond base polymer selection, coatings and treatments tailor webbing for extreme or specialized environments. Let’s examine the most critical enhancements:

UV Stabilizers

- Hindered Amine Light Stabilizers (HALS): Chemically bond to the polymer, neutralizing free radicals generated by UV exposure.

- Performance Gain: Up to a 70% reduction in tensile loss after 1,000 hours UV testing.

- Application: Ideal for rooftop cargo straps, marine dock lines, and outdoor signage webbings.

Water-Repellent & Anti-Fouling Coatings

- Silicone & Fluoropolymer Finishes

- Mechanism: Lower surface energy, causing water to bead and roll off.

- Benefits: <1% water absorption vs. 6% untreated nylon, reducing microbial growth and mildew.

- Anti-Fungal/Biocide Treatments

- Use Case: In humid or tropical zones, mould can weaken fibers; treating with biocides extends working life by up to 40%.

Flame-Retardant Finishes

- Standards Compliance: NFPA 701, FAR 25.853 for aerospace use.

- Chemistries: Brominated or phosphorus-based additives that promote char formation and limit oxygen to flames.

Anti-Static & Conductive Coatings

- Purpose: Disperse static buildup in environments with electronic components or flammable dust.

- Implementation: Conductive yarns or surface treatments, adding less than 5% to overall webbing thickness.

Coating Durability & Reapplication

- Wash-Fastness: High-quality finishes endure ≥20 machine washes without losing repellency.

- Recoat Cycles: Some coatings can be reapplied in the field—useful for long-term installations like architectural tension membranes.

By integrating these treatments at the fiber or fabric stage, Szoneier ensures that each tie down webbing is engineered to resist the exact threats posed by your operating environment—be it UV, moisture, mold, fire, or static.

Are There Eco-Friendly Options for Tie Down Webbing?

Recycled PET webbings, organic cotton, and bio-based polyamides (e.g., nylon from castor oil) offer sustainable alternatives, reducing carbon footprints by up to 60% while maintaining 70–90% of the strength of virgin materials.

As eco-conscious sourcing becomes a competitive advantage, sustainable tie down webbing options can align your operations with corporate responsibility goals and meet green procurement criteria.

Recycled Polyester (rPET)

- Source Materials: Post-consumer plastic bottles shredded, melted, and re-extruded into PET fibers.

- Performance: Retains ~95% of virgin PET tensile strength; UV and abrasion resistances are largely equivalent.

- Environmental Impact: Lifecycle analyses show a 50–60% reduction in greenhouse gas emissions compared to virgin PET.

Organic & Reclaimed Cotton

- Organic Cotton: Grown without synthetic pesticides/fertilizers—biodegradable but with tensile limits of 6 kN for 2″ webbing.

- Reclaimed Cotton: Up to 30% recycled cotton content blended into new yarns; reduces water consumption by 70%.

Bio-Based Polyamides

- Nylon 5,10 & 4,10: Derived partially from castor oil; offer 70–80% of 6,6 nylon strength with a 30–40% lower carbon footprint.

- Mechanical Properties: Slightly higher moisture absorption; UV resistance similar to conventional nylon when treated.

Certifications & Labels

- Global Recycled Standard (GRS): Verifies recycled content and processing.

- OEKO-TEX® Standard 100: Ensures no harmful substances are present—a selling point for textile-sensitive industries.

- Cradle to Cradle (C2C): Assesses full lifecycle sustainability.

Cost & Adoption Challenges

- Pricing: rPET is typically 5–10% more expensive than virgin PET; bio-pa nylons command a 20–30% premium.

- Supply Chain: Availability can be regionally limited; lead times may extend by 2–4 weeks.

Choosing eco-friendly webbings doesn’t require sacrificing performance. By partnering with Szoneier, you can access certified sustainable materials tailored to your load and environmental requirements—demonstrating your commitment to both safety and the planet.

How Should You Match Webbing Materials to Your Specific Application?

Assess load type (static vs. dynamic), environmental conditions (UV, moisture, chemicals), regulatory requirements, and cost constraints. Create a decision matrix scoring each material across these criteria to identify the optimal choice.

Selecting the perfect tie down webbing is a multi-criteria decision requiring a structured approach. Below is a step-by-step methodology to guide your selection:

Define Application Parameters

- Load Characteristics:

- Static Loads: Minimal movement—prioritize UV resistance and low stretch (polyester).

- Dynamic Loads: Frequent shocks—choose high-elongation, high-toughness materials (nylon).

- Environmental Exposures:

- Sunlight/UV: Opt for solution-dyed polyester or HDPE.

- Marine & Chemicals: Lean toward hydrophobic fibers (polyester, PP).

- Cold/Heat Extremes: Check temperature ratings; polyester tolerates higher heat.

- Regulatory & Safety Standards:

- Transportation (DOT, EN): Ensure WLL markings, specified safety factors.

- Aerospace (FAR, NFPA): Require flame-retardant and anti-static finishes.

Establish Evaluation Criteria

| Criterion | Weight (%) | Nylon Score (1–5) | Polyester Score (1–5) | PP Score (1–5) | Cotton Score (1–5) |

|---|---|---|---|---|---|

| Tensile Strength | 25 | 5 | 4 | 3 | 1 |

| UV Resistance | 20 | 3 | 5 | 2 | 1 |

| Abrasion Resistance | 15 | 5 | 4 | 2 | 2 |

| Moisture Resistance | 10 | 2 | 5 | 4 | 1 |

| Cost | 10 | 3 | 3 | 5 | 2 |

| Eco-Friendliness | 10 | 2 | 3 | 4 | 5 |

| Regulatory Compliance | 10 | 5 | 5 | 3 | 1 |

| Total (Weighted) | 100 | 3.9 | 4.1 | 3.3 | 1.6 |

Example scoring matrix—adjust weights and scores per your priorities. In this scenario, polyester scores highest due to balanced UV, moisture, and regulatory performance.

Run Cost-Benefit Analysis

- Initial vs. Lifecycle Costs:

- Polyester may cost 10% more upfront than PP but lasts 2–3× longer outdoors—yielding lower total cost per year.

- Maintenance & Replacement Frequency:

- Nylon straps in UV-rich climates may require annual replacement; polyester can extend to 3–5 years.

Prototype & Field Test

- Sample Runs: Order small batches from Szoneier for real-world trials—measure stretch, inspect wear, collect user feedback.

- Data Logging: Use load cells and strain gauges to record performance under operational conditions.

Final Selection & Customization

- Color-Coding & Branding: Szoneier offers custom colors and private label printing for easy inventory management and brand visibility.

- Special Requirements: Add edge-protective sleeves, customized coatings, or sewn loops to integrate seamlessly with your equipment.

By systematically defining your application needs, quantitatively evaluating materials, and validating through field tests, you ensure an optimal webbing choice. And with Szoneier’s flexible manufacturing, you can fine-tune every specification—from fiber type to finishing touch—to precisely match your operational demands.

Ready to Secure Your Cargo with Confidence?

At Szoneier, we combine 18+ years of expertise in webbing R&D, manufacturing, and sales to deliver custom tie down solutions—from high-strength nylon straps to eco-friendly recycled polyester webs. Whether you need low MOQ runs, rapid sampling, or private-label OEM/ODM production, our team ensures 100% quality assurance, free design services, and industry-leading lead times.

Contact us today for a personalized quote and discover how our custom tie down webbing can enhance safety, durability, and sustainability in your operations.

Secure your loads, protect your reputation, and optimize your costs—partner with Szoneier for the best tie down webbing materials on the market.