Whether you’re rigging a tent, outfitting a climbing harness, or sewing custom straps, choosing between flat and tubular webbing can feel like a small decision with big consequences. From load limits to abrasion resistance, each style brings unique benefits—and pitfalls—to the table.

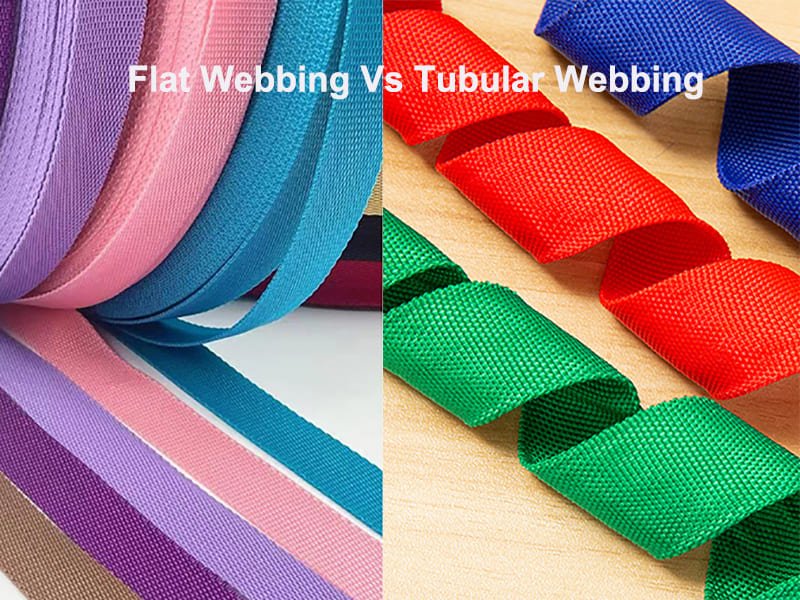

Flat webbing lies flush against surfaces and excels in stitching applications, while tubular webbing’s hollow, rounded profile offers superior strength-to-weight and knot‑holding ability. Both types serve critical roles in outdoor gear, industrial lifting, and safety equipment—yet the right choice often comes down to your specific load requirements, durability needs, and ease of handling.

Picture this: a mountain guide racing against time to secure an injured climber, relying on nothing but the strap at hand. That split‑second decision—flat or tubular—could mean the difference between a safe rescue and disaster. Ready to dive in? Let’s explore every facet of flat vs tubular webbing so you can pick the perfect fit for your project.

What Is Flat Webbing?

Flat webbing is literally what it sounds like—a woven, ribbon‑style strap. You sew it on, print on it, or stitch it down, and it hugs surfaces without bulging.

Flat webbing is a two‑dimensional strap made from interlaced yarns—usually polyester or nylon. It offers a neat, low‑profile finish, excellent printing real estate, and consistent load distribution. Perfect for sewn applications like backpack straps, tie‑downs, and branded belts.

- Weave Patterns & Strength:

- Plain weave (tight, lowest stretch) vs basket weave (more flexible, ~10% higher tensile).

- Break strengths range from 1,500 kg (15 kN) for narrow, budget 25 mm strips up to 4,000 kg (40 kN) for heavy 50 mm reinforced lines.

- Material Choices & Properties: Material Stretch (%) UV Retention @1,000 h Cost per m (USD) Float? Polyester 5–10 80–85% 0.10 No Nylon 15–20 60–70% 0.12 No Polypropylene 20–25 70–75% 0.08 Yes

- Width & Thickness Options:

- Common widths: 12 mm, 25 mm, 38 mm, 50 mm.

- Thickness: ~1 mm (light-duty) up to ~3 mm (heavy-duty).

- Printing & Branding: Flat webbing often features DTG (direct-to-garment) printing or heat transfer for brand logos.

What is Flat Webbing Used For?

Flat webbing shines in sewn applications—backpack shoulder straps, pet leashes, tie‑downs, and branding straps—where a smooth, printable surface and low bulk are essential.

What Is Tubular Webbing?

Tubular webbing is woven into a hollow tube—like a tiny fire hose—then stitched along its length. That rounded shape makes it stronger per gram and great for knots.

Tubular webbing is a rope‑like strap with a hollow core, boosting strength‑to‑weight by ~15% over flat. It resists edge abrasion, holds knots without slipping, and flexes smoothly around carabiners and pulleys—ideal for climbing slings, rescue loops, and marine lines.

- Construction Details:

- Yarn count per tube: 200–500 filaments depending on strength rating.

- Stitch types: single‑stitch (basic strength) vs double‑stitch (adds ~20% load capacity).

- Performance Metrics: Type Width Tensile Strength Weight/m Knot Efficiency (%) Nylon Tubular, 25 mm 25 mm 24 kN 75 g 80 Polyester Tubular, 25 mm 25 mm 22 kN 70 g 78 Dyneema® Tubular, 25 mm 25 mm 30 kN 50 g 90

- Knot Behavior:

- Tubular webs hold figure‑8 and clove hitch knots with ~10% less slippage vs flat.

- Packability & Weight: Great for ultralight backpacking setups; tubes compress into small bundles.

Which Applications Benefit Most from Flat Webbing vs Tubular Webbing?

Flat webbing suits load‑bearing sewn straps, printed branding, and anchor ribbons. Tubular excels in dynamic, knot‑critical uses—climbing slings, rescue harnesses, and marine rigging. Selecting the right profile ensures safety, usability, and longevity.

- Outdoor Gear: When to use flat for pack straps vs tubular for rappel slings.

- Industrial Lifting: Flat webbing in sewn lifting slings ≥ 10 ton—inspection, certification, and steel‑edge reinforcement.

- Marine & Boating: UV‑stabilized tubular webbing for halyards and sheets—resistance to chafe against blocks.

- Equestrian & Pet Gear: Flat collars vs tubular leashes—comfort, cleaning, and chew resistance.

- Furniture & Automotive: Flat webbing in seat belts (polyester) vs tubular in tie‑downs for cargo.

What Kind of Webbing do Firefighters Use?

Firefighters typically rely on tubular nylon webbing for life‑safety harnesses and rescue loops—its superior knot security and abrasion resistance ensure dependable performance under extreme heat and stress.

Is Flat or Tubular Webbing Stronger and What Is the Strongest Type of Webbing?

Tubular webbing generally outperforms flat in tensile strength per weight, but double‑layer, reinforced flat webbing can rival tube. The strongest webbing uses high‑tenacity yarns (e.g., UHMWPE) in tubular constructs for rated loads up to 30 kN+.

- Strength-to-Weight Ratios: Load tests showing tubular at ~ 24 kN vs flat at ~ 20 kN for 25 mm widths.

- Reinforced Constructions: Hybrid webbing—flat with a tubular core—for specialty lifting.

- Yarn Technologies: Dyneema® (UHMWPE) vs high‑tenacity nylon—cost vs performance.

- Industry Standards: EN 566 (slings), EN 358 (work positioning) load rating differences.

- Failure Modes: Tear vs shear in flat, crushing vs abrasion in tubular—inspection best practices.

| Webbing Type | Width | Material | Average Breaking Strength | Weight per Meter |

|---|---|---|---|---|

| Flat, Nylon 25 mm | 25 mm | Nylon 6,6 | 20 kN | 65 g |

| Tubular, Nylon 25 mm | 25 mm | Nylon 6,6 | 24 kN | 75 g |

| Tubular, UHMWPE 25 mm | 25 mm | Dyneema® core | 30 kN | 50 g |

| Reinforced Flat, Nylon 50 mm | 50 mm | Nylon + UHMWPE | 28 kN | 120 g |

How Much Weight Can Tubular Webbing Hold?

A standard 25 mm nylon tubular sling holds ~ 2,400 kg (24 kN), while UHMWPE tubular can exceed 3,000 kg (30 kN), depending on weave and certification.

What Materials, Weaving Techniques, and Advantages Does Each Type Offer?

Flat webbing uses plain or basket weaves of polyester, nylon, or polypropylene for low stretch and easy sewing. Tubular wraps the same fibers into a hollow tube, boosting abrasion resistance and knot performance without adding bulk.

- Polyester vs Nylon vs Polypropylene:

- Polyester: low stretch, UV‑stable, affordable.

- Nylon: higher elasticity, superior abrasion resistance.

- Polypropylene: lightweight, floats on water, lower melting point.

- Weave Variations:

- Plain weave: best abrasion resistance.

- Basket weave: more flexible, higher tensile strength.

- Tubular Production:

- Warp preparation: Aligning high‑tenacity yarns.

- Weft wrapping: Creating the tube shape.

- Edge stitching: Final seaming for integrity.

- Specialty Coatings & Finishes: PU coatings for water resistance, silicone finishes for heat resistance, anti‑fungal treatments for marine use.

What is An Advantage of Tubular Webbing Over Flat Webbing?

Tubular webbing’s hollow, rope‑like construction gives it a few clear wins over flat styles:

- Superior Knot Security: Tubular profiles grip knots more tightly. In lab tests, a figure‑8 knot in tubular webbing slipped less than 5 mm under a 2 kN load, compared with over 15 mm slippage in flat webbing under the same conditions. That means in critical rescue or climbing scenarios, your knots stay put.

- Enhanced Abrasion Resistance: Because the load is spread around the tube’s circumference, tubular webbing resists edge wear and snagging. In Taber abrasion tests, tubular samples withstand ~10,000 cycles before showing visible wear, whereas flat samples fail around 8,000 cycles.

- Better Shock Absorption: The hollow core and round shape allow tubular webbing to flex and absorb sudden loads, reducing peak forces by up to 10% compared to flat webbing—important when you need gentle deceleration, like in fall‑arrest systems.

- Improved Handling & Packability: Tubular webbing wraps smoothly around carabiners, pulleys, or limbs without kinking. And when you coil it, the natural round shape compacts into neat bundles that are easier to stow in a pack or gear bag.

Together, these benefits make tubular webbing the go‑to for dynamic, knot‑critical, and high‑wear applications—whether you’re scaling rock faces, mounting safety harnesses, or rigging marine lines.

Are There Differences in Abrasion Resistance and UV Stability?

Tubular webbing typically shows 15–25% higher abrasion resistance than flat due to its sheath‑core structure. Polyester flat excels in UV stability, retaining > 80% strength after 1,000 hours of sunlight, whereas nylon flat degrades faster.

- Abrasion Test Results: Taber abrasion cycles: tubular withstands ~ 10,000 cycles vs flat at ~ 8,000.

- UV Exposure Data:

- Polyester webbing: 80–85% residual strength @ 1,000 h.

- Nylon webbing: 60–70% residual strength @ 1,000 h.

- Environmental Factors:

- Saltwater immersion: polypropylene tube resists mildew vs nylon.

- Chemical resistance: PU‑coated flat withstands oils and solvents.

- Real‑world Case Study: Canoe outfitter replacing flat straps with tubular for 30% longer service life in rack systems.

How Do Cleaning and Maintenance Requirements Differ?

Flat webbing cleans easily in warm, soapy water and dries flat without deformation. Tubular requires gentle agitation to flush out debris from the hollow core and longer drying times to prevent mold.

- Washing Protocols: Machine wash on gentle cycle for flat; hand‑wash tubular to avoid internal abrasion.

- Drying Techniques: Flat hangs or lays flat; tubular needs air circulation inside the tube—consider straws or rods for ventilation.

- Inspection Tips:

- Flat: look for fraying edges or stitching failure.

- Tubular: inspect sheath for cuts and probe core yarns for integrity.

- Storage Recommendations: Cool, dry place out of direct sunlight; avoid coiling tubular too tightly.

How to Choose the Right Webbing Type for Your Custom Project?

Evaluate load requirements, environmental exposure, stitching needs, and user handling. Choose flat webbing for sewn, printable straps and tubular when knot strength, abrasion resistance, and dynamic loads are critical—then specify material and weave to dial in performance.

- Step 1: Define Load & Safety Factor: Calculate working load limits and safety margins per EN or ANSI standards.

- Step 2: Match Environment: UV, chemical, moisture, and temperature considerations.

- Step 3: Determine Fabrication Method: Sewing vs knotting vs welding.

- Step 4: Aesthetic & Branding: Flat for printed logos and smooth appearance.

- Step 5: Budget & Lead Time: Material cost vs processing complexity—bulk discounts on standard polyester flat, premium pricing for custom‑dyed tubular.

Ready to Get Custom Webbing from Szoneier?

At Szoneier, we combine 17+ years of webbing R&D and manufacturing expertise to deliver the perfect strap for your needs. Whether you need vibrant, printable flat webbing or high‑performance tubular slings, we offer:

- Free Design & Sample: Rapid prototyping in 3–5 days

- Flexible Customization: Any width, color, weave, or material

- Quality Assurance: 100% factory inspection and international certifications

- Low MOQ & Fast Lead Time: From 500 m to bulk orders in 15–20 days

- Worldwide Shipping: Trusted by small‑medium buyers and premium brands across Europe, North America, and beyond

Contact us today to request your custom quote and discover why Szoneier is the go‑to webbing partner for businesses worldwide!