When it comes to hauling, transporting, or securing heavy loads, one tool stands out for its unbeatable strength and versatility: the ratchet strap. Whether you’re a trucker securing a pallet, a homeowner moving furniture, or a weekend warrior strapping down a motorcycle, knowing how to use a ratchet strap properly is essential—not only for safety, but for getting the job done right the first time.

Ratchet straps are load-securing tools that use tension and locking mechanisms to keep items in place during transport. They’re widely used in trucking, logistics, shipping, and even daily life. To use them correctly, you attach the strap ends to anchor points, tighten via the ratchet handle, and lock the strap in place.

Many people misuse ratchet straps without realizing it: overtightening fragile cargo, choosing the wrong strap type, or threading incorrectly. In this article, we’ll break down everything you need to know about using ratchet straps safely, efficiently, and confidently. And at the end, we’ll show you how Szoneier can help with custom webbing straps for your unique needs.

What Are Ratchet Straps and How Do They Work?

Ratchet straps are adjustable tie-down tools that use a ratcheting mechanism to create high tension and secure heavy loads during transport.

Understanding the Components

Every ratchet strap is made up of several key parts that work together to safely hold your load:

| Component | Description |

|---|---|

| Ratchet Handle | The lever that allows you to crank and apply force to the webbing. |

| Webbing Strap | Made from high-tensile synthetic fibers like polyester, nylon, or PP. |

| End Fittings | These are hooks or rings that attach to anchor points. |

| Release Lever | A small handle that releases the tension and opens the ratchet mechanism. |

Why They Work So Well

The mechanical advantage offered by the ratcheting system is the secret to their strength. Unlike bungee cords or cam straps that rely on elasticity or friction, ratchet straps let you tighten the load incrementally. This makes them:

- Reliable over long trips

- Safer under heavy stress

- More adjustable than stretch cords

Cam Buckles vs. Ratchets

| Feature | Ratchet Straps | Cam Buckle Straps |

|---|---|---|

| Tension Mechanism | Mechanical Ratchet | Friction Grip |

| Load Capacity | Up to 10,000 lbs+ | Usually < 800 lbs |

| Use Case | Heavy-duty transport | Light-duty, indoor or short haul |

| Safety | Very secure, locks in place | May slip if overloaded |

Which Types of Ratchet Straps Are Commonly Used?

Different ratchet straps are designed for different weights, environments, and securing needs.

Load Capacity Breakdown

Here’s a quick guide to choosing the right strength:

| Type of Ratchet Strap | Working Load Limit (WLL) | Breaking Strength | Use Cases |

|---|---|---|---|

| Light-Duty (1 inch) | 500–1,000 lbs | ~1,500–3,000 lbs | Bikes, small boxes, general household use |

| Medium-Duty (1.5 inch) | 1,000–2,500 lbs | ~3,000–6,000 lbs | ATVs, general cargo, mid-sized equipment |

| Heavy-Duty (2-4 inch) | 3,000–10,000+ lbs | ~9,000–20,000 lbs | Construction materials, pallets, machinery |

Hook & End Fittings

- S-Hooks: Great for everyday jobs like tying furniture.

- Flat Hooks: Perfect for flatbeds or trailers.

- Snap Hooks: Secure because they latch closed.

- D-Rings: Often paired with carabiners or custom loops.

Material Comparison

| Material | Strength | Stretch | Weather Resistance | Common Usage |

|---|---|---|---|---|

| Nylon | High | Moderate | Medium | Flexible loads, recovery gear |

| Polyester | Very High | Low | High | General purpose, trucking |

| Polypropylene | Low | High | Low | Light-duty, budget-friendly |

How to Properly Use Ratchet Straps: A Step-by-Step Tutorial

Using a ratchet strap involves attaching the ends, threading the webbing, applying tension with the ratchet, and locking it in place.

Step-by-Step: How to Tie Down a Load

Let’s walk through a complete, real-world example of how to properly use a ratchet strap to secure cargo—like a motorcycle or heavy appliance in a trailer.

1. Choose the Right Strap

- First, ensure your ratchet strap matches the job. Check the Working Load Limit (WLL) printed on the label or tag. For motorcycles, a strap rated for at least 1,500 lbs is usually ideal.

2. Find Solid Anchor Points

- Attach each hook (or loop end) to strong, fixed anchor points on the trailer or truck bed—like built-in D-rings, rails, or frame tie-downs. Avoid makeshift anchor spots.

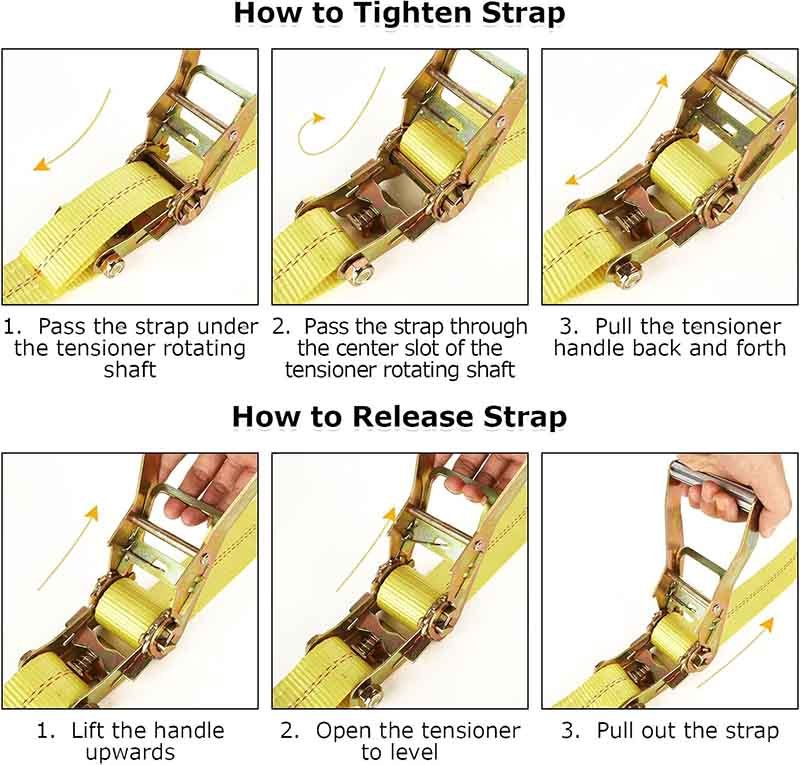

3. Thread the Webbing Properly

- Feed the free end of the strap through the mandrel slot in the center of the ratchet from the bottom up. Pull it through until taut but not tight.

4. Eliminate Slack by Hand

- Pull the webbing with your hand to take out all slack before you start ratcheting. This reduces the number of pumps needed and ensures uniform tension.

5. Tension with the Ratchet

- Pump the ratchet handle back and forth. Each crank tightens the strap incrementally. Don’t over-crank—tighten until firm, not until it’s digging into your cargo.

6. Lock the Handle

When you reach desired tension, close the ratchet handle fully. It will lock into place. Test by gently tugging on the strap—there should be zero give.

7. Secure Excess Strap

Roll up or tie off the loose end using Velcro, zip ties, or by tucking it into the webbing. Unsecured straps can flap in the wind, weaken over time, or cause distraction.

8. Double-Check All Points

Walk around your load. Confirm that nothing has shifted, and every anchor and strap is locked. If it’s a long haul, stop and inspect again mid-journey.

Illustrated Quick Reference Table

| Step | What to Do | Why It Matters |

|---|---|---|

| Choose Strap | Confirm WLL ≥ your load | Prevents failure from under-rated equipment |

| Attach Hooks | Use only rated anchor points | Ensures load won’t come loose during movement |

| Thread Strap | From bottom up through mandrel | Proper threading allows correct tensioning |

| Pull Slack | Tighten by hand first | Reduces effort and improves safety |

| Ratchet to Tension | Use smooth, controlled cranks | Prevents overtightening and stress on the strap |

| Lock Handle | Fully close until it clicks | Keeps strap tension secure over long distances |

| Secure Excess Webbing | Tie, roll, or tuck loose ends | Prevents flapping, tangling, and potential hazard |

| Final Check | Inspect all anchor and strap positions | Adds extra safety and peace of mind |

Tips for Special Situations

- Hauling motorcycles or bikes? Use soft loops to avoid scratching painted parts.

- Transporting fragile furniture? Add foam or edge guards under straps.

- Moving multiple boxes? Use multiple straps spaced evenly to distribute pressure.

- Rainy or icy weather? Double-check tension; wet straps can shrink or shift when drying.

This process may take just a few minutes, but it’s worth every second. Proper use of ratchet straps prevents property damage, personal injury, and road accidents—making them an essential tool in everyday logistics.

Are Ratchet Straps Safe for All Loads?

Ratchet straps are safe for most loads when used within their working load limits and with proper tensioning techniques.

Important Ratings to Know

| Term | Meaning |

|---|---|

| Working Load Limit | The maximum safe force you can apply (usually 1/3 of break strength) |

| Breaking Strength | Maximum force before the strap fails |

Formula: If your ratchet strap has a breaking strength of 6,000 lbs, then the WLL is likely 2,000 lbs.

Safety Checklist

- Inspect every strap before use: frays, burns, cuts?

- Don’t use if tags are missing—they usually list the WLL.

- Never attach to sharp edges or unstable anchor points.

- Don’t use household hooks or DIY anchors—they can fail under tension.

Weather Awareness

- Wet polyester straps retain strength but can freeze.

- Nylon absorbs more water and stretches—adjust tension accordingly.

- Avoid direct sunlight over long periods: UV can degrade webbing over time.

What Mistakes Should You Avoid When Using Ratchet Straps?

Avoid overtightening, misthreading, or using damaged straps to ensure safety and long strap life.

Most Common Errors

| Mistake | Risk |

|---|---|

| Overtightening | Dents, crushed cargo, broken fasteners |

| Threading incorrectly | Slippage and false sense of security |

| Using torn webbing | Full strap failure under stress |

| Not securing excess | Flapping straps can damage cargo or unwind over time |

Real Situations

- A customer moved antique furniture and overtightened the straps. The table’s legs cracked due to excess force.

- A motorcyclist reused old straps left in sunlight. One broke mid-drive, and the bike leaned dangerously.

Fix It Tips

- Learn the correct tension level for different cargo types.

- Don’t use a strap older than 5 years without inspection.

- Store in shaded, dry locations to extend life.

How Do You Maintain and Store Ratchet Straps for Longevity?

Ratchet straps last longer when cleaned, stored dry, and inspected regularly for wear or damage.

Cleaning Instructions

- Rinse dirt with warm water.

- Use mild detergent for grease.

- Avoid machine washing (can weaken fibers).

Drying and Storage

- Hang straps to dry naturally—never tumble dry.

- Roll loosely and store in a bin or drawer.

- Use silica gel packets to absorb moisture in containers.

Full Maintenance Table

| Task | Frequency | Tip |

|---|---|---|

| Visual Inspection | Before every use | Check for fraying, color fading, stitching |

| Cleaning | As needed | Especially after exposure to salt or chemicals |

| Lubricate Ratchet | Quarterly | Use WD-40 or light oil for smooth function |

| Replace Strap | If damaged | Don’t try to repair cuts or burns |

When to Retire a Strap

- Fraying that covers more than 10% of strap width.

- Buckles or hooks that have bent out of shape.

- Stitching that’s come undone.

Conclusion:

If you’re a brand, retailer, or bulk buyer looking to source high-quality ratchet straps with custom webbing, branded labels, or specialized hook types—Szoneier has you covered. With over 18 years of experience in webbing R&D and manufacturing, we offer:

- OEM/ODM production with low MOQs

- Polyester, nylon, PP, and cotton webbing options

- Custom logos, colors, and designs for branding

- Free samples, rapid prototyping, and strict QC on every order

Contact our expert team at Szoneier today and let’s tailor the perfect ratchet strap solutions for your market, your brand, and your customers.