In today’s fast-paced industrial landscape, ensuring both safety and efficiency in lifting operations isn’t just a “nice-to-have”—it’s mission critical. Synthetic slings have surged in popularity across construction sites, shipping docks, and manufacturing floors because they blend high strength with low weight, offering advantages that traditional steel slings simply can’t match.

Synthetic slings are high-strength, flexible lifting straps made from materials like nylon, polyester, and polypropylene. They outperform steel slings in weight, handling, and reduced load damage, making them ideal for diverse lifting applications.

Imagine a massive I-beam suspended high above a busy worksite. A steel sling might scratch or dent the beam’s surface; a synthetic sling, however, wraps gently around the load, protecting both the beam’s finish and the workers’ hands. This small difference can mean fewer damaged goods, lower insurance claims, and a safer environment—for both your team and your bottom line. Stick around to uncover the secrets behind synthetic slings and why leading brands choose Szoneier for tailor-made lifting solutions.

What Are the Different Types of Synthetic Slings?

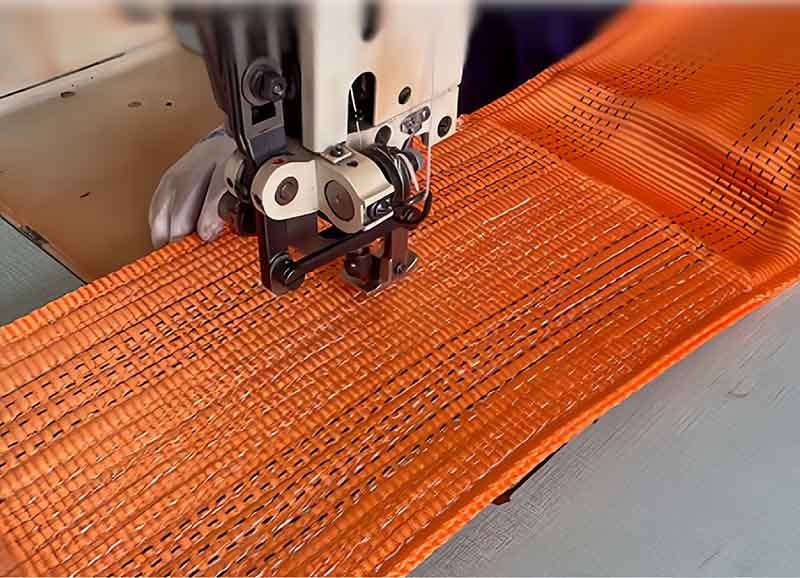

Synthetic slings are typically made from nylon, polyester, or polypropylene fibers. Nylon slings offer elasticity and shock absorption, polyester slings resist UV and moisture, and polypropylene slings excel in lightweight corrosive-environment lifting. Each material’s weave style—round, flat, or braided—further tailors the sling’s strength, flexibility, and abrasion resistance.

Synthetic slings come in a variety of constructions, each optimized for certain tasks:

Nylon Slings:

- Properties: High elasticity (up to 8% elongation), absorbs shock loads, superior strength-to-weight ratio.

- Use Cases: Ideal for delicate or precision lifts where shock absorption prevents load swing.

- Limitation: Sensitive to acids, chemicals, and sunlight; not recommended for outdoor, prolonged exposure.

Polyester Slings:

- Properties: Minimal stretch (<3%), excellent UV and moisture resistance, good chemical resistance.

- Use Cases: Best for outdoor heavy-duty lifts, marine environments, and situations requiring minimal load shift.

- Limitation: Slightly heavier than nylon, marginally less shock absorption.

Polypropylene Slings:

- Properties: Very lightweight, floats on water, resistant to alkalies and most chemicals.

- Use Cases: Common in marine, chemical, and food-processing industries.

- Limitation: Low melting point (~160 °C), limited strength compared with nylon and polyester.

Weave Styles & Configurations:

- Round Slings: Consist of continuous yarn encased in a protective sleeve—flexible, smooth on load, but limited to straight pulls.

- Flat Web Slings: Broad, flat strap—excellent surface contact and stability; may kink under uneven loads.

- Endless Braided Slings: Yarn braided into a circle—uniform strength distribution and easy to inspect for damage.

| Material | Max Working Load | Elongation | Best Environment |

|---|---|---|---|

| Nylon | 1–100 tonnes | 6–8 % | Indoor, controlled |

| Polyester | 1–80 tonnes | 2–3 % | Outdoor, marine |

| Polypropylene | 0.5–20 tonnes | 5–7 % | Chemical, food |

By selecting the right combination of material and weave, you optimize load safety, sling longevity, and operational efficiency. Szoneier offers customization across all these variants, ensuring the perfect sling for your unique needs.

How Do Synthetic Slings Work?

Synthetic slings lift loads by distributing weight evenly across strong, flexible fibers. Unlike steel wire, they conform to the load’s shape, reducing pressure points and preventing damage. Load capacity is determined by sling width, material grade, and sling angle—ensuring precise control over working load limits.

At their core, synthetic slings convert tensile stress in the fibers into lifting force. When you attach a sling to a load:

Load Distribution: The broad surface of a webbing sling—especially flat or round constructions—spreads the tension over a wider area, minimizing dents or scratches.

Elasticity & Shock Absorption: Elastic components in nylon and polypropylene slings absorb sudden jolts or jerky movements. This prevents load swinging, reduces peak stresses on the fibers, and enhances operator safety.

Rigging Angle Considerations: Sling angle—formed between two legs in a basket or choker hitch—affects the required sling strength. A 120° angle, for example, increases the effective load on each leg by ~15% compared to a straight vertical lift. Proper angle selection is vital to avoid accidental overload.

Rated Working Load Limit (WLL):

- Derived from the sling’s Minimum Breaking Strength (MBS) divided by a Safety Factor (typically 5:1).

- Always reference manufacturer charts—Szoneier slings are clearly color-coded and tagged with WLL, MBS, and angle ratings for unambiguous use.

Attachments & Hardware: Synthetic slings often pair with soft shackles, alloy hooks, or custom fittings. These accessories must match the sling’s strength ratings to maintain system integrity.

By understanding these mechanical principles, you ensure that each lift is performed within safe thresholds, maximizing sling lifespan and worker confidence.

What Are the Benefits of Using Synthetic Slings?

Synthetic slings offer superior strength-to-weight ratios, enhanced load protection, and improved operator safety. Their flexibility reduces damage to finished surfaces, while low weight minimizes worker fatigue. Plus, they’re non-conductive—ideal near electrical hazards—and simple to inspect for wear.

Lightweight Handling:

- Synthetic slings can weigh as little as 5% of equivalent steel wire rope slings.

- Reduced sling weight means fewer strains and faster rigging/unrigging, saving time and labor costs.

Surface Protection:

- The soft, pliable fibers wrap smoothly around loads, eliminating gouges or scratches common with wire rope or chain slings.

- Critical for handling painted or polished components in automotive, aerospace, and architectural industries.

Non-Conductivity:

- Unlike steel, synthetic fibers do not conduct electricity.

- Essential for utility work near live lines or in environments with potential electrical hazards.

Enhanced Safety:

- Visual damage indicators (e.g., colored core in round slings) alert operators to worn or cut fibers.

- Synthetic slings do not whip back dangerously if they fail—they sag, reducing risk to nearby personnel.

Versatility & Customization:

- Szoneier provides custom lengths, widths, and protective sleeves—perfect for unique load geometries.

- Optional edge guards and abrasion pads add local reinforcement where needed most.

Reduced Maintenance Costs:

- Corrosion-resistant fibers eliminate rust inspections or lubrication cycles required by steel slings.

- Chemical-resistant variants stand up to oils, solvents, and cleaning agents common in industrial settings.

Investing in synthetic slings translates to fewer lost production hours, lower insurance claims for load damage, and a safer, more efficient operation overall.

Which Industries Rely on Synthetic Slings?

Synthetic slings are indispensable in construction, shipping, oil & gas, chemical processing, and manufacturing. Their adaptability allows for safe handling of precast concrete, steel beams, delicate machinery, and even bulk materials. Each sector benefits from specialized sling designs that meet stringent safety standards.

Construction & Infrastructure:

- Precast Concrete Handling: Wide synthetic slings wrap precast panels uniformly, avoiding edge cracks.

- Steel Erection: Polyester slings resist UV and weather exposure on outdoor job sites.

- Bridge & Tunnel Maintenance: Soft slings protect tunnel linings and bridge girders during lift-and-set operations.

Maritime & Shipping:

- Container Handling: Polypropylene slings float, making water recovery easy if accidentally dropped overboard.

- Deck Rigging: Nylon slings absorb shock from deck sway, minimizing load swing in rough seas.

Oil & Gas & Petrochemical:

- Pipe Lifting: Chemical-resistant slings stand up to hydrocarbon exposure.

- Drilling Rig Movements: Low-weight slings speed up drill-pipe changes, reducing downtime.

Manufacturing & Assembly:

- Machinery Relocation: Soft slings prevent scratching of precision equipment during relocation or maintenance.

- Automotive Body Panels: Nylon slings eliminate dents on painted surfaces during chassis assembly.

Renewable Energy:

- Wind Turbine Components: Lightweight polyester slings handle massive blades without imparting stress concentrations.

- Solar Panel Installation: Flat web slings minimize pressure points on glass panels.

Entertainment & Events:

- Stage Rigging: Non-conductive slings are critical for lighting trusses near live electrical fixtures.

- Exhibition Installations: Gentle handling of artwork and displays without protective intermediate packaging.

Szoneier’s 18+ years in webbing and sling customization ensures each sector finds an optimized solution—backed by data-driven engineering and rigorous quality control.

Are Synthetic Slings Environmentally Friendly?

Many synthetic slings are recyclable and have a lower carbon footprint than steel wire slings. Their long service life reduces waste, and materials like polypropylene can be reclaimed. Proper end-of-life disposal involves shredding and repurposing fibers, minimizing landfill contributions.

Lifecycle Analysis:

- Production Impact: Manufacturing synthetic fibers consumes less energy and emits fewer CO₂ equivalents than steel wire production.

- In-Use Longevity: High abrasion resistance and UV stabilization extend sling lifespan—some Szoneier slings last 5+ years in harsh environments.

Recyclability:

- Polypropylene & Polyester: Both materials are commonly accepted in industrial recycling streams.

- Nylon: More challenging but can be chemically depolymerized into monomers for new fiber production.

Waste Reduction:

- Modular Components: Replaceable sleeves and end fittings mean you often discard less material at retirement.

- Upcycling Programs: Szoneier partners with recycling facilities to collect used slings and reprocess them into industrial yarns.

Regulatory Compliance:

- Meets ISO 9001 quality standards and ISO 14001 environmental management systems.

- Documentation provided for cradle-to-grave tracking to support corporate sustainability reporting.

Carbon Footprint Comparison Table

| Sling Type | CO₂ Emissions per kg Produced | Typical Service Life | Total CO₂ per Year of Service |

|---|---|---|---|

| Steel Wire | 2.5 kg CO₂ | 3 years | 0.83 kg CO₂/year |

| Polyester | 1.1 kg CO₂ | 5 years | 0.22 kg CO₂/year |

| Nylon | 1.7 kg CO₂ | 4 years | 0.43 kg CO₂/year |

By choosing high-quality synthetic slings from Szoneier, you not only enhance operational performance but actively reduce your environmental footprint.

What Are the Key Maintenance Tips for Synthetic Slings?

Inspect slings before each use for cuts, abrasions, and UV damage. Store dry, away from sunlight and chemicals. Remove or repair slings showing wear beyond manufacturer’s tolerance. Rotate sling legs to balance wear evenly, and follow load-angle guidelines to prevent overload.

Pre-Use Inspection:

- Visual Checks: Look for fraying edges, broken yarns, discoloration (UV damage), or melted fibers.

- Tag Verification: Ensure the identification tag is legible—if missing, retire the sling immediately.

Periodic Detailed Inspection:

- Downtime Reviews: At least every 3 months under heavy use, every 6 months under moderate use.

- Professional Assessment: Use magnification or fiber testing equipment to detect sub-surface damage.

Cleaning & Storage:

- Clean with Mild Detergent: Remove oils, dirt, and chemicals that might degrade fibers.

- Dry Completely: Moisture promotes mold and weakens fibers for nylon slings in particular.

- Avoid Direct Sunlight: Prolonged exposure to UV rays reduces strength over time.

Rotational Use & Load Distribution:

- Rotate slings among different loads to ensure even wear across the entire fleet.

- Alternate sling leg positions in basket or double-leg lifts.

Repair & Retirement:

- Minor Repairs: Szoneier offers onsite restitching for protective sleeves—but never apply field repairs to load-bearing yarns.

- Retirement Criteria: Remove any sling with ≥10% broken fibers in a given section, visible core in round slings, or degraded stitching.

Effective maintenance extends sling life by up to 30% and avoids catastrophic failures—protecting both people and equipment.

How Do You Choose the Right Synthetic Sling for Your Application?

Select slings based on load weight, load shape, environment, and required working angle. Consider material compatibility (chemicals, UV), necessary elongation, and protective accessories. Always verify manufacturer’s WLL and angle-rating charts to match your specific lifting scenario.

Define Load Characteristics:

- Weight & Center of Gravity: Determines sling width and number of legs (single, double, multi-leg).

- Load Geometry: Sharp corners require edge protectors; irregular shapes may need custom cradle slings.

Environmental Factors:

- Temperature Extremes: Polypropylene melts above 160 °C; nylon degrades in acids.

- Chemical Exposure: Polyester slings resist most solvents; polypropylene excels in alkaline conditions.

Lifting Configuration & Angle:

- Vertical Lift: Straight pull—simplest, highest WLL.

- Choker Hitch: Wraps around load—WLL reduces by ~25%.

- Basket Hitch: Doubles capacity under ideal angles but watch angle reduction factors.

Regulatory & Safety Standards:

- Ensure compliance with ASME B30.9, EN 1492, or relevant regional codes.

- Check for third-party testing certificates (e.g., TÜV, SGS).

Customization Options:

- Szoneier can engineer slings with specialized coatings (fire-retardant, anti-static), color-coding for quick identification, and RFID tags for digital inspection records.

By working with Szoneier’s engineering team, you’ll receive a data-backed recommendation that balances safety, cost, and operational efficiency—guaranteeing the right sling for every lift.

Conclusion: Are Synthetic Slings the Right Choice for Your Business?

Synthetic slings represent a paradigm shift in material handling—marrying lightweight design with robust strength, environmental stewardship, and unparalleled versatility. From nylon’s shock-absorbing prowess to polyester’s weather resilience and polypropylene’s chemical compatibility, there’s a sling optimized for virtually every industry challenge.

Ready to optimize your lifting operations? Contact Szoneier today to discuss custom synthetic sling solutions tailored to your exact specifications. With 18+ years of R&D and manufacturing expertise, we guarantee 100% quality, low MOQs, rapid sampling, and dedicated OEM/ODM support. Elevate your safety and efficiency—reach out for a quote now!