Modern lifting operations demand the right sling for safety, efficiency, and cost‑effectiveness. From rugged alloy‑steel chain slings powering heavy lifting in steel mills to ultra‑gentle polyester web slings handling delicate glass panels, each sling type brings unique benefits and trade‑offs. Whether you’re hoisting machinery across a dusty construction site or carefully positioning precision‑machined parts in a factory, understanding sling construction, load capacity, inspection practices, and environmental sensitivities is critical.

Slings come in three main categories—chain, wire rope, and synthetic—each tailored for specific loads and conditions. Chain slings offer exceptional durability for heavy, abrasive environments; wire rope slings balance flexibility with strength; synthetic slings (webbing and round) minimize surface damage and weight. Choosing the right sling hinges on load weight, temperature, surface sensitivity, and regulatory standards.

Picture this: you’re on a job site where a 5‑ton gearbox needs to be precisely positioned inside a machine frame. The wrong sling could mean delays, damaged equipment, or worse—safety hazards. In this article, we’ll walk you through every sling option, unpack the critical specs, compare performance under stress, and share expert tips on maintenance and inspection. By the end, you’ll have the confidence to specify the ideal sling from Szoneier’s custom catalog—perfectly matched to your lifting challenge, every time.

What Are the Different Types of Slings?

There are three principal sling categories:

- Chain Slings: Alloy‑steel links for the toughest, high‑temperature, and abrasive lifts.

- Wire Rope Slings: Flexible, heat‑resistant steel strands for hoisting and towing.

- Synthetic Slings: Nylon or polyester fibers in webbing or round‑configurations to protect sensitive loads and reduce sling weight.

Dive Deeper

1. Chain Slings

Chain slings, forged from high‑strength alloy steel, stand out for exceptional abrasion resistance and high-temperature tolerance (up to around 425 °C). Their modular link design allows damage replacement—critical in heavy‑duty industries like metal forging, shipbuilding, and mining. Chains can be tailored in single‑leg, two‑leg, or multi‑leg configurations with hooks, master links, and safety latches. However, the weight of chain slings (often 2–3 kg per meter) requires robust handling equipment, and their rigid links can scratch or dent delicate surfaces.

2. Wire Rope Slings

Constructed from multiple strands of galvanized or stainless steel wire, these slings offer a balance of flexibility and tensile strength. Standard constructions include six‑strand and eight‑strand rope, available in open‑or closed‑throat ferrule terminations or socketed eyes. Wire rope slings handle temperatures up to 250 °C for galvanized and up to 550 °C for stainless variants, making them versatile across manufacturing, marine, and utility sectors. They resist moderate abrasion but can kink if misused. Periodic lubrication and careful reeving are essential to prevent core fatigue and broken wires.

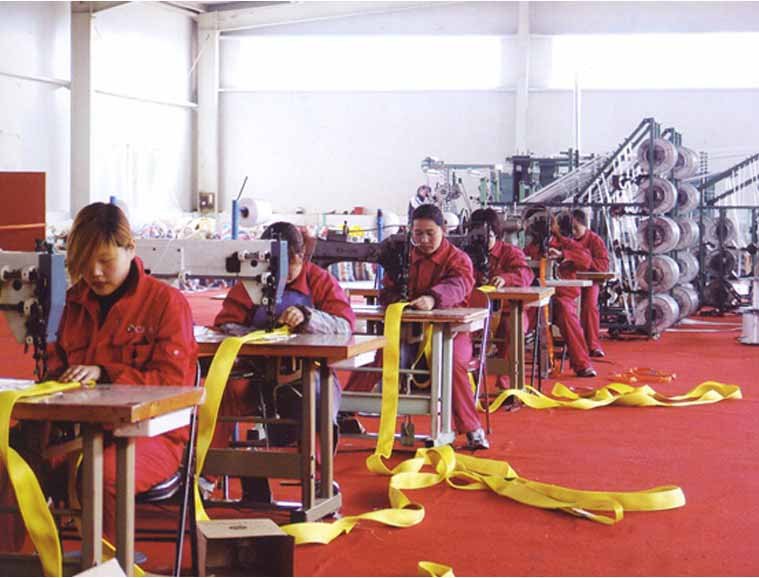

3. Synthetic Slings

Lightweight yet strong, synthetic slings are made from continuous nylon or polyester fibers woven into flat webbing or bound into round “endless” slings. They typically carry working load limits (WLL) from 0.5 tonne to 15 tonnes, depending on width and ply. Polyester’s low stretch (~2 %) and superior UV resistance make it ideal for outdoor use; nylon’s higher stretch (~8 – 10 %) can absorb shock loads. Unlike steel slings, synthetic options won’t mar surfaces, are non‑conductive, and float on water—perfect for marine, glass, and stone industries. Yet, they degrade under strong acids, alkalis, and temperatures above 80 °C.

4. Comparative Overview

| Sling Type | WLL Range (tonnes) | Temp. Rating | Weight (per m) | Surface Safety | Repairability | Typical Uses |

|---|---|---|---|---|---|---|

| Chain Sling | 1 – 50+ | –40 °C to 425 °C | 2–3 kg | Low | High | Steel mills, foundries, heavy machinery |

| Wire Rope Sling | 0.5 – 30 | –40 °C to 550 °C | 1.2–1.8 kg | Medium | Medium | Construction, towing, marine, utilities |

| Web Sling | 0.5 – 15 | –40 °C to 80 °C | 0.2–0.5 kg | High | Low | Glass handling, precision assembly, furniture |

| Round Sling | 0.5 – 20 | –40 °C to 80 °C | 0.25–0.6 kg | High | Low | Textile, glass, electronics, light machinery |

Selecting among these depends on lifting weight, environment, load sensitivity, and budget. In the following sections, we’ll dissect each aspect so you can make an informed decision.

What Is a Webbing Sling and How Is It Used?

A webbing sling is a flat, woven synthetic sling—typically polyester or nylon—featuring looped eyes or metal fittings at each end. It distributes load evenly across a broad surface, preventing damage to delicate materials. Used widely in manufacturing, glass installation, and furniture assembly, webbing slings handle weights from 0.5 tonne to 15 tonnes, offer up to 10 % elastic stretch for shock absorption, and are non‑conductive—ideal anywhere electrical safety or surface protection is critical.

Webbing slings consist of multiple plies of high‑strength synthetic fibers stitched together to form a flat load‑bearing body. Key characteristics include:

- Load Distribution: The flat design spreads force over several inches of contact area, reducing point pressure that could dent or crack fragile loads like glass panes or coated metal sheets.

- Material Choice – Nylon vs. Polyester:

- Nylon Webbing: Higher elongation (8–10 %) absorbs shock but is susceptible to moisture uptake, causing slight strength loss when wet.

- Polyester Webbing: Low elongation (2–3 %) ensures precise load control, resists UV degradation, and maintains strength when exposed to rain or humidity.

- End Fitting Options:

- Reinforced Eyes: Simple, heat‑sealed loops for indoor use and light‑duty.

- Steel Thimbles & Fittings: Galvanized or stainless‑steel thimbles protect the eye from abrasion; hardware options include grab hooks, slip hooks, or D‑rings for secure attachments.

- Typical Configurations:

- Single‑Leg: Simplest form—one eye‑to‑eye sling.

- Multi‑Leg (Bridle): Two or more legs branching from a common master link for balanced multi‑point lifts.

- Choker Hitch: Loop passed through one eye and around the load to create a choking action—but reduces WLL by about 25 %.

- Applications & Benefits:

- Glass & Marble Handling: Protective, non‑abrasive contact.

- Precision Assembly: No stretch creep means tight tolerances.

- Constrained Spaces: Flexible and lightweight—easy to maneuver.

- Limitations & Care: Synthetic fibers are vulnerable to sharp edges, chemicals (strong acids/alkalis), and heat above 80 °C. Edge protection (corner guards, sleeves) and regular inspections for cuts, frays, or UV bleaching are mandatory.

By understanding webbing sling construction, you can match sling specs to your application—whether it’s a delicate electronics assembly or a multi‑point structural steel lift. Szoneier offers custom webbing slings in nylon or polyester, with any fitting or length you require.

Which Materials Are Most Common in Sling Construction?

Sling materials fall into three groups:

- Alloy Steel: Used in chain slings for maximum abrasion and temperature resistance.

- Galvanized or Stainless Wire Rope: Provides flexibility and corrosion resistance for diverse hoisting and marine applications.

- Synthetic Fibers (Nylon/Polyester): Lightweight, non‑abrasive, and non‑conductive—ideal for handling delicate or moisture‑sensitive loads.

Material selection drives sling performance, safety, and longevity. Let’s explore each in detail:

- Alloy Steel (Chain Slings):

- Composition & Treatment: Quenched and tempered chains often exceed 800 MPa tensile strength. Alloying elements—nickel, chromium, molybdenum—enhance hardness and fatigue resistance.

- Heat Tolerance: Maintains structural integrity up to 425 °C. Surface‑hardened links resist abrasion from rough loads.

- Corrosion Concerns: Uncoated steel is vulnerable to rust; galvanized finishes add decades of outdoor life.

- Wire Rope (Steel Strands):

- Strand Configurations: Six‑strand (1×7 core) offers exceptional fatigue life, while eight‑strand (2×19 core) maximizes flexibility.

- Protective Coatings: Galvanization shields against rust; stainless steel slings excel in high‑humidity, coastal, or food‑processing environments.

- Crushing & Kinking: Proper reeving through sheaves and gentle handling are essential to avoid broken wires, which compromise safety.

- Synthetic Fibers:

- Nylon: Strong, elastic, and energy‑absorbing—ideal for shock loads but absorbs up to 10 % of its weight in water, reducing strength slightly when wet.

- Polyester: Low stretch and excellent UV resistance make it the go‑to for outdoor cranes, telecom installations, and marine lifts.

- Comparative Table of Material Properties:

| Property | Alloy Steel | Galvanized Wire Rope | Stainless Wire Rope | Nylon Webbing | Polyester Webbing |

|---|---|---|---|---|---|

| Tensile Strength (MPa) | 800 – 1,200 | 600 – 900 | 500 – 850 | 50 – 70 | 60 – 80 |

| Elongation at Break (%) | 12 – 15 | 10 – 12 | 8 – 10 | 8 – 10 | 2 – 3 |

| Temperature Rating | –40 °C to 425 °C | –40 °C to 550 °C | –40 °C to 550 °C | –40 °C to 80 °C | –40 °C to 80 °C |

| Abrasion Resistance | Very High | High | High | Moderate | Moderate |

| Chemical Resistance | Low | Medium | High | Low | Medium |

| Weight per Meter (kg/m) | 2–3 | 1.2–1.8 | 1.3–1.9 | 0.2–0.5 | 0.2–0.5 |

Custom Material Blends:

At Szoneier, we can manufacture hybrid solutions—e.g., steel‑core synthetic slings for combined strength and weight savings, or polyurethane-coated wire ropes for enhanced abrasion resistance.

Selecting the right material means balancing strength, flexibility, environmental exposure, load type, and operational speed. Talk to our engineers to specify the perfect material combination for your unique lifting challenges.

What Are the Various Types of Webbing Slings?

Webbing slings come in two main styles:

- Flat Web Slings: Flat, looped slings with steel fittings or sewn eyes, ideal for smooth load distribution.

- Round Slings: Endless circular slings with a protective fabric sleeve, providing uniform load dispersion and easy repositioning.

Each style offers distinct performance benefits depending on load shape, hitch type, and handling needs.

Webbing slings shine when weight needs broad, non‑abrasive contact:

- Flat Web Slings:

- Construction: Multiple synthetic fiber plies (2‑ply to 8‑ply) stitched together and heat‑sealed to form looped ends or fitted with thimbles.

- Benefits:

- Load Orientation: Precise vertical, choker, or basket hitches.

- Hardware Integration: Easily fitted with hooks, shackles, or D‑rings.

- Use Cases: Coil lifting, steel plate handling, machinery installation.

- Round Slings:

- Design: Continuous loop of high‑tensile yarns encased in a tubular polyester or nylon jacket. Color‑coded by capacity simplifies quick identification.

- Benefits:

- Flexibility: Conforms around irregular shapes—ideal for pipes, cylinders, and finished components.

- Protective Sleeve: The outer jacket safeguards internal fibers from abrasion and UV damage.

- Use Cases: Vessel maintenance, woodworking, HVAC equipment positioning.

- Edge Protection & Accessories:

- Corner Guards: Rigid or flexible corner pads to prevent fiber cutting on sharp edges.

- Protective Sleeves: Replaceable polyester jackets extend sling life when brushing against rough surfaces.

- Identification Tags: Durable, weatherproof labels with load charts, serial numbers, and inspection dates ensure compliance.

- Capacity & Color Coding:

- Standard Colors (per EN 1492‑1):

- Violet (1 t), Green (2 t), Yellow (3 t), Grey (4 t), Red (5 t), etc.

- Markings: WLL, serial number, manufacturer, standard compliance (e.g., EN, ASME B30.9) clearly printed on tags.

- Standard Colors (per EN 1492‑1):

- Inspection & Lifespan:

- Daily Visual Checks: Look for cuts, burns, or stitching failure.

- Periodic Detailed Inspections: Every 6 months (or every 3 months for severe service) by a qualified inspector.

- Replacement Criteria: Any strand cut, cover abrasion exceeding 50 % of thickness, or tag illegibility mandates sling removal.

By choosing between flat web and round styles—and adding the right protection—you can optimize load control, operator safety, and sling longevity. Szoneier’s in‑house textile shop produces webbing slings to any ply, length, and fitting specification you require.

How Do Textile Slings Compare to Chain and Wire Rope Slings?

Textile slings (web and round) are lighter, non‑abrasive, and non‑conductive compared to steel slings. They’re ideal for delicate loads and tight spaces but have lower temperature tolerance (–40 °C to 80 °C) and reduced chemical resistance. Chain and wire rope slings excel in high‑heat, heavy, abrasive environments but can damage sensitive surfaces and require more cumbersome handling.

Choosing between textile and steel slings often comes down to job‑site specifics:

- Weight & Handling:

- Textile: Typical web sling weighs 0.3 kg/m versus 2 kg/m for chain—dramatically reducing operator fatigue and speeding up rigging.

- Steel: Heavier gear demands overhead cranes or mechanized trolleys for safe positioning.

- Surface Protection:

- Textile: Cushions corners and prevents marring—critical for painted, plated, or polished surfaces.

- Steel: Without protective sleeves, chain links can scratch and dent.

- Temperature & Chemical Resistance:

- Textile: Limited to 80 °C; vulnerable to acids, alkalis, and solvents. Not recommended near molten materials or chemical exposure.

- Chain/Wire: Alloy steel retains strength at high temperatures; stainless wire rope resists corrosion in chemical plants.

- Flexibility & Hitch Variability:

- Textile: Can cinch tight around odd shapes; ideal for basket or choker hitches.

- Steel: Requires additional hardware or shackles for choker arrangements; less conforming to shape.

- Cost & Lifecycle:

- Textile: Lower upfront cost, but shorter service life in abrasive or chemical environments.

- Steel: Higher upfront investment; can be refurbished by link replacement or re‑spooling, extending usable life.

- Inspection Complexity:

- Textile: Visual checks for cover damage and fiber exposure are straightforward but require careful tag legibility checks.

- Steel: Wire rope inspections demand checking for broken wires, corrosion, and core damage; chain requires measuring link wear with go/no‑go gauges.

In many operations, a hybrid approach—steel slings for the “dirty,” high‑heat lifts and textile slings for cleanroom or precision work—yields optimal productivity and safety. Szoneier can engineer both steel and synthetic sling systems with integrated hardware to suit any modular rigging plan.

How Do You Select the Proper Sling Based on Load Capacity and Application?

Select a sling by matching its Working Load Limit (WLL) to your maximum lift weight, then adjust for hitch type (vertical, basket, choker), angle factors, and dynamic conditions. Always include a safety factor—typically 5:1 for synthetic and 4:1 for steel. Confirm material compatibility with temperatures, chemicals, and surface sensitivity before final selection.

Proper sling selection demands careful calculation and application awareness:

- Working Load Limit (WLL) & Safety Factor:

- Definition: WLL is the maximum load a new sling can lift under ideal conditions.

- Safety Factor: Minimum 5:1 for synthetic, 4:1 for wire rope, and 4:1 for chain, meaning a 5 t web sling can hold 1 t safely in shock‑free lifts.

- Hitch Configurations & Angle Factors:

- Vertical Hitch: Full WLL but only one lift point.

- Basket Hitch: WLL increases by up to 2× when the sling wraps under the load—angle must exceed 120°.

- Choker Hitch: Reduces WLL by about 25 % due to rope constriction.

- Angle Factor Table:

- Dynamic vs. Static Loads:

- Static: Gradual lifting—standard WLL applies.

- Dynamic/Shock: Sudden starts/stops or load sway—reduce WLL by additional 20 %.

- Environmental & Load Considerations:

- Temperature Extremes: Above 80 °C, avoid textile slings. Above 250 °C, prefer stainless wire rope or alloy steel.

- Chemical Exposure: Use stainless steel for acids; polyester slings resist mild alkalis.

- Surface Finish: Choose protective‑sleeved web slings for glossy or painted items.

- Customized Sling Assemblies:

- Multi‑leg bridle slings for long, heavy loads.

- Swivel hooks and rotating fittings to prevent sling twist.

- Synthetic‑core slings with steel outer wires for advanced hybrid performance.

- Calculation Workflow:

- Determine maximum load weight.

- Choose hitch type and calculate angle factor.

- Select minimum WLL = (Load ÷ Angle Factor) × Safety Factor.

- Check material and temperature compatibility.

- Confirm fitting types and lengths.

By following this systematic approach, you’ll ensure each sling assembly is tailored precisely to your application—no overkill, no under‑rating. Szoneier’s engineers can run these calculations and deliver certified, ready‑to‑use sling kits to your dock.

What Are the Key Safety Standards and Inspection Practices for Slings?

Critical standards include ASME B30.9 (U.S.) and EN 1492‑1 (Europe). Inspect slings daily for cuts, corrosion, or deformation; perform formal inspections every 6 months (3 months for severe service). Remove any sling showing broken wires, exposed fibers, or illegible tags. Maintain detailed inspection logs to ensure compliance and traceability.

Rigorous safety protocols underpin every professional lifting operation:

- Relevant Standards:

- ASME B30.9 (Slings): Covers design, manufacturing, testing, and safe use in North America.

- EN 1492‑1 & 1492‑2: European norms for flat webbing and round slings, respectively.

- ISO 9927 & ISO 4309: General crane and wire rope inspection guidelines.

- Inspection Types & Frequency:

- Daily/User Inspection: Visual check before each use—look for cuts, crushed fibers, bent links, broken wires, or chemical damage.

- Periodic/Detailed Inspection: Every 6 months under normal service; every 3 months in severe, high‑cycle, or corrosive environments. Conducted by a competent person per standard definitions.

- Common Failure Indicators:

- Chain Slings: Excessive wear (more than 10 % link elongation), bent or gouged links, cracked welds.

- Wire Rope: More than 7 broken wires in one strand or 3 broken wires in one lay length; core protrusion.

- Textile Slings: Cuts or tears deeper than 10 % of yarn diameter, melting or charring, UV bleaching, or tag illegibility.

- Recordkeeping & Traceability: Each sling must carry a unique serial number and manufacturer’s tag. Inspection logs should record: date, inspector name, findings, corrective actions, and next inspection due date. Digital inspections apps can streamline compliance and reminders.

- Removal & Disposal Criteria: Standards mandate immediate removal from service for any sling with critical damage. Textile slings are cut into unusable lengths before disposal to prevent unauthorized reuse.

- Training & Competency: Operators and riggers require formal training on sling types, load charts, angle calculations, and inspection techniques. Regular refresher courses and on‑site toolbox talks reinforce best practices.

By adhering to recognized standards, maintaining disciplined inspection routines, and investing in staff training, you reduce downtime, avoid accidents, and extend sling service life. Szoneier supplies fully tagged, test‑certified slings and can assist with on‑site inspection training for your team.

How Do You Maintain and Prolong the Lifespan of Your Slings?

Proper sling maintenance includes regular cleaning (water and mild detergent for synthetics; wire brushing for steel), storing off‑ground in dry, UV‑protected areas, avoiding chemical exposure, and using edge‑protection accessories. Conduct daily visual inspections and adhere to periodic detailed checks. Rotate slings in high‑cycle operations to balance wear.

Routine care and smart handling practices dramatically extend sling life:

- Cleaning & Storage:

- Textile Slings: Wash with water and mild soap after contact with dirt, oil, or chemicals. Hang to dry away from direct sunlight.

- Steel Slings: Remove rust and debris with wire brushes; apply light oil or protective grease to prevent corrosion.

- Storage: Store in a cool, dry locker or cabinet—slings should never rest on floors or near heat sources.

- Edge & Corner Protection: Always use polyurethane corner protectors or heavy‑duty sleeves when lifting sharp‑edged materials. This prevents cut‑through and extends service life by up to 3×.

- Load Rotation & Balancing: In high‑cycle environments (e.g., steel coil handling), rotate sling legs regularly so each leg experiences equal wear. Label legs and track usage hours to schedule retirements before fatigue failure.

- Avoid Overloading & Shock Loading: Educate operators to lift smoothly—sudden jerks or rapid starts can impose dynamic loads exceeding static WLL by 20 %. Use soft‑start crane controls or shock absorbers where possible.

- Environmental Controls:

- UV Exposure: Polyester resists UV better than nylon, but both degrade over time—avoid continuous outdoor storage without covers.

- Chemical Exposure: Keep slings away from concentrated acids, alkalis, solvents, or prolonged saltwater immersion.

- Repair & Refurbishment:

- Chain Slings: Certified workshops can replace damaged links and restore WLL.

- Wire Rope: Professional re‑spooling and pressing of new end fittings extend life if core integrity remains sound.

- Textile Slings: Customsafety patches can cover minor abrasions, but major tears or burned areas require full replacement.

- Documentation & Traceability: Maintain clear logs of cleaning dates, repairs, and retirement schedules. Digital asset management systems can automate alerts for upcoming maintenance or end‑of‑life.

By treating slings as precision tools rather than disposable straps, you unlock maximum ROI and maintain safer lifting operations. Szoneier not only supplies high‑quality slings but also offers maintenance kits, protective accessories, and live training sessions to keep your rigging department in top shape.

Conclusion

Choosing the right sling—chain, wire rope, webbing, or round—requires balancing load capacity, environmental factors, surface sensitivity, and safety standards. Armed with clear WLL calculations, hitch‑angle adjustments, and rigorous inspection protocols, you can optimize both safety and productivity on every lift.

Ready to specify custom slings engineered to your exact requirements? Contact Szoneier today for a tailored quote on any sling type, size, material, or assembly. Our expert team will guide you through selection, certification, and delivery—ensuring your next lift is the safest and most efficient one yet.