Ever driven down a bumpy road wondering if that pallet of stuff in your trailer is going to stay put? Tie downs aren’t just straps—they’re your guarantee that everything from furniture to forklifts arrives in one piece.

Tie downs are tensioned straps, chains, or ropes rated to bear specific loads, designed to pin cargo firmly in place. They stop shifting, sliding, and spills, keeping drivers safe and avoiding costly damage.

Picture this: a furniture mover once lost a $5,000 antique chair because a worn strap snapped. Since then, they switched to high-grade 2″ polyester ratchet straps with a 10,000 lb breaking strength—and never looked back.

What Is a Tie Down and Why Is It Essential for Securing Loads?

Tie downs are more than just straps or chains—they’re critical safety devices that prevent cargo disasters. By applying controlled tension and leveraging friction, tie downs lock your load to the trailer bed, stopping forward, backward, and lateral movement.

According to the Federal Highway Administration, unsecured or poorly secured cargo causes over 500,000 crashes annually in the U.S., resulting in more than 800 deaths and 60,000 injuries each year. The average cost per accident hovers around $23,000 when you factor in vehicle damage, cargo loss, and liability claims.

| Metric | Value |

|---|---|

| Annual crashes from shifted loads (FHWA) | 500,000+ |

| Fatalities from load-related incidents (FHWA) | 800+ per year |

| Injuries from load-related incidents (FHWA) | 60,000+ per year |

| Average accident cost (property & cargo) | $23,000 |

| Recommended safety margin above cargo weight | 25–50% extra WLL |

Tie downs also ensure compliance with federal regulations—FMCSA 49 CFR §393.100 mandates that every commercial vehicle must secure cargo with devices rated for the weight and type of load. Failing to meet these standards can lead to fines up to $10,000 per violation and suspension of operating privileges.

Beyond legal requirements, proper tie down use enhances operational efficiency:

- Reduced downtime: Fewer load shifts mean less time re-adjusting cargo on long hauls.

- Lower insurance premiums: Insurers often reward companies with proven cargo-securement programs.

- Brand reputation: Delivering undamaged goods builds trust with customers and partners.

Whether you’re hauling lumber, machinery, or high-value retail pallets, quality tie downs are your first line of defense against risk.

What do Americans call ratchet straps?

Over here, we usually say “ratchet straps” or “ratchet tie downs.” Truckers might call them “cargo straps,” and movers often refer to them as “lashing straps.”

Which Materials and Constructions Are Commonly Used for Tie Downs?

Not all tie downs are created equal. Here’s a quick look at the most popular materials:

| Material | Typical WLL (lbs) | Stretch (%) | UV Resistance | Weight per 10 ft |

|---|---|---|---|---|

| Polyester Webbing | 2,500–15,000 | < 5% | High | ~ 1.2 lbs |

| Nylon Webbing | 3,000–20,000 | 15–25% | Moderate | ~ 1.3 lbs |

| Steel Chain (Grade 70) | 10,000–30,000 | 0% | Excellent | ~ 20 lbs |

| Polypropylene Rope | 1,200–5,000 | 20–30% | Low | ~ 0.8 lbs |

- Polyester webbing is the go-to: minimal stretch, excellent UV resistance, mildew-proof. Ideal for permanent outdoor fleets.

- Nylon webbing cushions sudden shocks—great for delicate machinery—but it stretches more and absorbs moisture.

- Grade 70 steel chain is fireproof and nearly indestructible, perfect for construction equipment, though it’s heavy.

- Polypropylene rope floats and is cheap, but it degrades faster in sunlight.

How Are Tie Downs Classified by Type and Strength Rating?

Tie downs come in flavors to match every job. Here’s a breakdown:

| Type | Mechanism | WLL Range (lbs) | Best For |

|---|---|---|---|

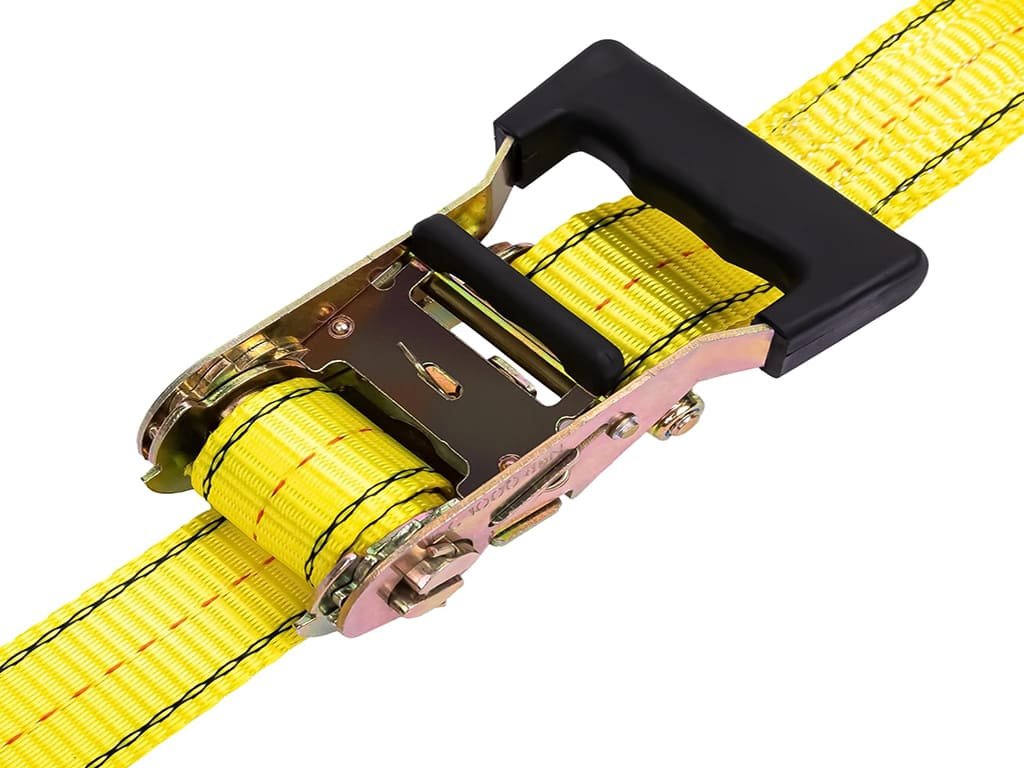

| Ratchet Straps | Gear-driven | 1,500–10,000 | Heavy pallets, equipment |

| Cam-Buckle Straps | Friction plate | 500–4,000 | Furniture, quick jobs |

| J-Hooks/S-Hooks | Hook ends | 1,000–6,000 | General hauling |

| Rope Lashings | Knots/hitches | Varies | Boats, logs |

| Chain Binders | Lever leverage | 5,000–30,000 | Construction vehicles |

- Working Load Limit (WLL) is the strap’s safe capacity; Breaking Strength is typically 3× WLL. Always choose a tie down whose WLL exceeds your cargo weight by 25–50% to account for dynamic forces.

- End fittings matter: flat hooks resist vibration slippage, snap hooks lock more securely but may rust if not stainless.

- Standards & Labels: Look for ANSI/ASME and DOT-compliant tags—these certify a strap’s tested performance.

How Do You Choose the Right Tie Down for Your Application?

Picking the perfect tie down is about matching specs to your load:

| Cargo Type | Recommended Strap | Min. WLL (lbs) | Key Feature |

|---|---|---|---|

| Machinery (2,000 lbs) | 2″ polyester ratchet strap | ≥ 2,500 | Low stretch, UV-proof |

| Furniture | 1″ cam-buckle strap | ≥ 1,000 | Fast setup |

| Logs & Lumber | ¾″ polypropylene rope | ≥ 1,200 | Cost-effective, floats |

| Heavy Construction | Grade 70 steel chain | ≥ 10,000 | Fire-resistant |

- Weight & Dimensions: Measure precisely—don’t guess.

- Safety Buffer: Add 25–50% on top of actual weight.

- Environment: Sun, salt, chemicals? Go UV- and corrosion-resistant.

- Handling & Storage: Heavier chains require lifting gear; lightweight webbing can roll tight for easy stowage.

For odd shapes—pipes, machinery with sharp edges—always use edge protectors and wider webbing to prevent cuts.

How Should Tie Downs Be Properly Installed, Tensioned and Released?

Getting it right every time takes practice:

- Route Straps Correctly: Crisscross over and under to stop lift.

- Remove Slack: Hand-tighten before ratcheting.

- Ratchet Technique: Two to three full ratchet cycles—enough to snug without crushing the load.

- Secure Loose Ends: Tie off or tuck away excess webbing to prevent wind damage.

- Safe Release: Stand clear, unlatch slowly, and guide the webbing in to avoid whipping back.

Common Pitfalls:

- Twisted Webbing: Cuts strength by up to 50%.

- Over-Ratcheting: Can damage both strap and cargo.

What Is the Difference Between a Ratchet Strap and a Tie Down Strap?

All ratchet straps are tie downs, but tie downs include a broader family:

| Feature | Ratchet Straps | Other Tie Downs |

|---|---|---|

| Tension Control | Geared, precise | Friction or manual leverage |

| Typical WLL | Up to 10,000 lbs | 500–30,000 lbs (chains) |

| Speed of Release | Slower | Fast (cam buckles/ropes) |

| Complexity | More moving parts | Simple, fewer parts |

| Cost | Higher | Varies (rope cheapest) |

Ratchets deliver maximum tension—ideal for heavy loads. Cam buckles and ropes win on simplicity and speed for lighter or frequent-change setups.

Do Tie Downs Need Regular Inspection and Maintenance?

Absolutely. A single worn strap can mean disaster:

| Component | Check For… | Frequency |

|---|---|---|

| Webbing | Cuts, tears, UV fading | Before every use |

| Hardware | Rust, bent hooks, stripped gears | Monthly |

| Labels | Legible WLL and standards info | Annually |

- Cleaning: Mild soap and water; never bleach.

- Lubrication: A drop of machine oil on ratchet gears keeps them smooth.

- Retirement: Replace straps older than 5 years or showing any damage—no patch jobs.

Ready to Secure Your Cargo with Confidence?

Whether you’re hauling lumber, equipment, or custom webbing products, Szoneier delivers tailor-made tie down solutions with guaranteed quality. Request your free design consultation and sample today—and haul smarter, safer, and simpler with Szoneier!