Outdoor chair webbing may sound like a small detail, but it’s actually the backbone of your favorite patio lounger or poolside chaise. It’s the flexible fabric strap that holds you up, keeps your seat taut, and resists sun, rain—and yes, the occasional spill.

Outdoor chair webbing is a woven or extruded fabric strap—usually polypropylene, polyester, or nylon—designed to provide both support and comfort for outdoor seating. It boasts high tensile strength, UV protection, and quick‑dry properties, making it essential for durable, weather‑resistant chairs that stay comfy season after season.

Think about that last time you sank into a saggy lawn chair—no fun, right? Stick around, and I’ll show you how to pick, install, and care for webbing that keeps seats snug and smiles wide.

What Is Outdoor Chair Webbing And Why Does It Matter?

It’s the strong, weather‑proof strap under your seat cushion or between your chair rails. Without it, outdoor chairs would collapse, sag, or wear out fast. Good webbing is the secret to both comfort and a long‑lasting patio setup.

- Why give up comfort? How webbing tension impacts your back

- Beyond support: the role webbing plays in overall chair design

- Frame love: matching webbing to metal, wood, or synthetic frames

Durability vs. Comfort

Choosing webbing involves a trade‑off between tensile strength and flexibility. For example, 1.5″ polypropylene straps offer exceptional load capacity (up to 450 lbs) but can feel firmer than 1″ polyester. Knowing how you’ll use the chair—lounging lightly versus supporting taller, heavier users—helps you find the sweet spot.

Aesthetics and Design

Webbing comes in a rainbow of hues and weaves, from solid blacks and earth tones to eye‑catching stripes. Outdoor brands often use woven patterns (herringbone, basket) not just for looks but also to enhance grip and comfort under bare skin.

Ergonomics and Load Distribution

Wider webbing spreads weight more evenly, reducing localized pressure on both the user and the chair frame. In high‑use commercial settings, 2″ webbing is common; for residential patio sets, 1″–1.25″ balances comfort with minimalist design.

What Is Lawn Chair Webbing Made Of?

Lawn chair webbing is woven from synthetic fibers—polypropylene for water‑fast, budget builds; polyester for UV‑resistance and colorfastness; nylon for top‑tier strength and flexibility. Each brings its own perks to the seat.

| Property | Polypropylene (PP) | Polyester (PET) | Nylon (PA66) |

|---|---|---|---|

| Water Absorption | < 0.01% | < 0.1% | ~ 4% |

| Tensile Strength (psi) | 6,000 | 8,000 | 10,500 |

| UV Stability (hours) | ~ 500 | ~ 1,000 | ~ 800 |

| Abrasion Cycles | 10,000 | 15,000 | 20,000 |

| Dry‑time after rain | < 5 min | < 10 min | < 15 min |

| Typical Cost/ft | $0.30–0.45 | $0.50–0.75 | $1.00–1.50 |

- PP dries in under 5 minutes and costs the least, but will fade fastest in full sun.

- PET holds dye for bright, fade‑resistant straps with mid‑range cost.

- Nylon offers top strength—ideal for heavy loads or marine use, at a higher price.

Which Materials Are Best Suited For Outdoor Chair Webbing?

Match your use: PP for casual yard chairs, PET for sunny decks, and nylon for commercial or marine settings. Each balances price against UV‑lifespan, tensile strength, and mildew resistance.

What Is The Best Webbing For Chairs?

For most homeowners, UV‑stabilized polyester (1″–1.25″ wide) nails the sweet spot: affordable, long‑lasting color, and dries fast. It’s the go‑to for pools, patios, and porches alike.

| Use Case | Material | UV Warranty | Load Cycles | Typical MOQ |

|---|---|---|---|---|

| Backyard Patio | PET | 2–3 years | 15,000 | 10 yd increments |

| Poolside Seating | PET + UV Inhibitor | 3–5 years | 18,000 | 5 yd increments |

| Café & Resort | Nylon (PA66) | 5+ years | 25,000 | 20 yd+ |

| Marine Deck Chairs | Marine Nylon + Biocide | 5+ years | 20,000 | 10 yd increments |

| Budget Folding Chairs | PP | 1–2 years | 8,000 | 25 yd+ |

- Residential: 2–3 year UV warranties suffice; choose colorfast PET.

- Resort/Commercial: look for 5+ year UV guarantees, 20,000+ abrasion cycles.

- Eco‑Friendly: rPET saves plastic bottles from landfill, with only a small cost premium (~$0.10/ft).

How Are Different Types Of Outdoor Chair Webbing Manufactured?

Outdoor chair webbing is produced via weaving, extrusion, or knitting processes. Weaving yields flat, strong straps; extrusion makes tubular webbing for cushions; warp‑knitting creates breathable meshes—each technique tailored to material and end‑use requirements.

| Process | Profile Type | Materials Used | Key Benefit |

|---|---|---|---|

| Flat Weaving | Flat Straps | PP, PET, PA66 | Precise width, heavy load support |

| Extrusion | Tubular Webbing | HDPE, LDPE blends | Soft cushion backing |

| Warp Knitting | Mesh Webbing | PET, PVC‑coated PET | Maximum breathability |

- Flat weaving: tight, reliable, cost‑effective straps.

- Extruded tubular: adds a comfy “give” under upholstery.

- Warp‑knitting: ideal for sling‑style chairs—lets air flow and water drain.

What Factors Determine The Durability And Weather Resistance Of Webbing?

Look at tensile strength, UV‑stability, abrasion cycles, water absorption, and mildew resistance. These specs tell you how long webbing holds up under sun, rain, salt spray, and heavy use.

| Property | PP | PET | PA66 |

|---|---|---|---|

| Tensile Strength (psi) | 6,000 | 8,000 | 10,500 |

| UV Stability (hours) | 500 | 1,000 | 800 |

| Abrasion Cycles | 10,000 | 15,000 | 20,000 |

| Water Absorption (%) | < 0.01 | < 0.1 | ~ 4 |

| Mildew Resistance | Low | High (with treatment) | High (with treatment) |

- High use: choose PA66 for 20,000+ abrasion cycles.

- Pure sun: PET’s 1,000 hour UV rating beats PP.

- Rainy climates: PP’s ultra‑low absorption is key—dries almost instantly.

How Do You Install And Replace Outdoor Chair Webbing Safely?

Installing outdoor chair webbing involves measuring strip lengths, securing ends with staples or screws, and tensioning evenly. Replacement follows the same steps in reverse: remove old webbing, prepare frame, and attach new straps using the correct knots or hardware.

Can you replace lawn chair webbing?

Yes—you can replace lawn chair webbing yourself. With basic tools (staple gun, scissors, measuring tape) and replacement straps, homeowners can restore chair support in under an hour per seat, extending furniture life and comfort.

Dive Deeper:

- Tools & Materials Needed: staples vs. screws vs. clips

- Step‑by‑Step Process: from removal to tensioning

- Safety Tips & Best Practices: avoiding tears and misalignments

Tools & Materials Needed

- Staple Gun or Upholstery Tacks: for wood frames

- Self‑Tapping Screws & Washers: for metal frames

- Measuring Tape & Chalk: ensure uniform lengths

- Webbing Straps & Tensioning Tools: manual or ratchet tensioners

Step‑by‑Step Process

- Remove Old Webbing: cut staples or screws, preserve pattern.

- Clean & Inspect Frame: remove rust, smooth edges.

- Measure & Cut New Straps: add 2-4″ extra for fastening.

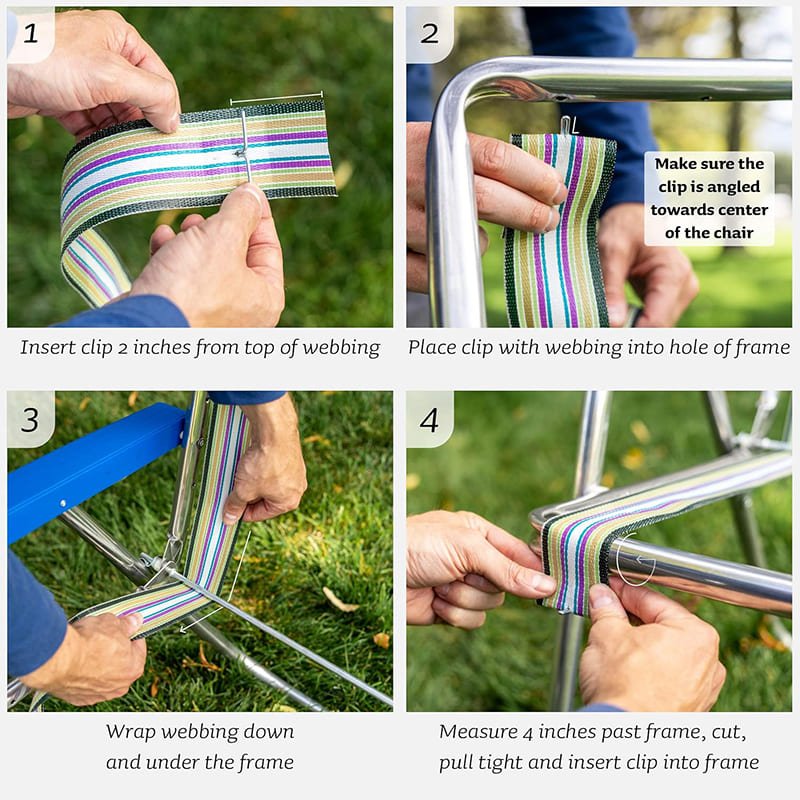

- Insert clip 2 inches from top of webbing.

- Place clip with webbing into hole of frame(Make sure the clip is angled towards center of the chair).

- Wrap webbing down and under the frame .

- Measure 4 inches past frame, cut, pull tight and insert clip into frame.

Safety Tips & Best Practices

- Wear gloves to avoid cuts from staples.

- Check frame integrity before reinstalling webbing.

- Test tension with weight to avoid overtightening and frame stress.

How Should You Clean And Maintain Outdoor Chair Webbing?

Clean webbing with mild detergent and a soft brush, rinse thoroughly, and air‑dry. For mildew, use a 1:10 bleach solution. Store chairs indoors or covered during harsh winters to prolong webbing life and color vibrancy.

| Task | Frequency | Method |

|---|---|---|

| Light Wipe‑Down | Monthly | Warm soapy water + soft cloth |

| Deep Scrub | Quarterly | Soft brush + mild detergent; rinse thoroughly |

| Mildew Treatment | As needed | 1:10 bleach solution; test small area first |

| UV Re‑application | Annually | Spray‑on UV protectant |

| Winter Storage | Seasonal | Keep chairs covered or indoors |

How Do You Choose The Right Outdoor Chair Webbing For Your Project?

Consider climate (UV, rain), load (light vs. heavy), usage (residential vs. commercial), aesthetic (colors, widths), and budget. Order samples, test left in sun for a week, and then pick the winner.

| Factor | Consideration | Example |

|---|---|---|

| Climate | UV hours, rainfall, salt air | Coastal home → marine nylon |

| Usage | Weight cycles, frequency of use | Café chairs → heavy nylon |

| Aesthetic | Color, weave pattern, width | Modern porch → 1″ black PET with white stripe |

| Budget | $0.30–$1.50 per foot | Tight budget → PP at $0.35/ft |

| Lead Time & MOQ | 7–10 days sample, 10 yd MOQ | Small batch → Szoneier’s low MOQ |

Conclusion:

Outdoor chair webbing is the key to sturdy, weather‑resistant seating—choosing between polypropylene, polyester, or nylon lets you balance strength, UV protection, and quick‑dry performance.

Ready to transform your outdoor seating into a durable, stylish haven? Partner with the Szoneier team for tailored webbing solutions—whether you need vibrant patio straps or heavy-duty, marine-grade designs. Enjoy complimentary design consultations, no‑cost sample swatches, and expert guidance from project start to finish. Let’s bring lasting comfort and eye‑catching style to your outdoor spaces!