When you pause to think how everyday straps—like those on your backpack, seat belt, or pet leash—are made, it can seem like a mystery. Yet behind every length of webbing is a carefully orchestrated five-step process. From selecting the right yarns to ensuring every inch meets strict strength and color standards, each phase matters.

The webbing process unfolds in five essential stages: raw material inspection, yarn preparation, weaving, dyeing & finishing, and final quality control. At our factory, we rigorously test yarn strength and colorfastness before weaving, employ specialized looms (plain, twill, herringbone) for different materials (nylon, polyester, PP, cotton), control dyeing parameters (temperature, pH, tension), and perform tensile, spectrophotometer, and dimensional checks to guarantee durable, custom webbing.

Imagine you’re a brand manager who just got a call from a client: “We need 10,000 meters of custom-colored, reflective strap for our new outdoor gear—and we need them next month.” Behind that request lies countless decisions: “Which raw yarn will handle outdoor UV exposure?” “How will we ensure the green color matches Pantone 347?” “What testing confirms it won’t snap under load?” This guide peels back the curtain, sharing stories, data, and examples so you’ll see exactly how we turn raw fibers into industrial-grade webbing you can trust.

What Is the Process of Webbing?

The webbing process involves five steps: choosing high-performance yarns, preparing and inspecting them for strength and colorfastness, weaving on specialized looms, dyeing and heat-setting under precise conditions, then performing tensile, color, and dimensional tests before packaging. Each phase is critical to create durable, custom webbing suited for OEM, private label, or ODM applications.

Defining Webbing Beyond a Strap

Many people think “webbing” is just a fancy name for “strap,” but in manufacturing terms, webbing is a tightly woven ribbon of yarns engineered to support loads, resist abrasion, and maintain shape. Whether you’re holding a backpack on your shoulders or securing a kayak, webbing does heavy lifting. It must balance flexibility (so it doesn’t chafe your skin) with rigidity (so it doesn’t stretch excessively).

Take a popular 50 mm nylon webbing used in outdoor gear. It must support at least 2,500 N (560 lbf) of load without compromising comfort. Contrast that with 25 mm polyester webbing on a seat belt: it needs a minimum breaking strength of 16 kN (3,600 lbf). Clearly, “webbing” isn’t one-size-fits-all; the term encompasses a range of materials, widths, and constructions for different uses.

Why Five Steps? The Logic of Our Workflow

Splitting the process into five steps ensures quality at each juncture. If you tried to weave first, dye later, then hope the color holds up, you’d end up with uneven shades and weak points. By inspecting raw materials, controlling weaving parameters, fine-tuning dye baths, and testing the end result, we minimize defects, reduce waste, and guarantee consistency—especially important when you order 10,000 meters and can’t afford a single meter that fails.

How This Process Differs for Custom vs. Stock Webbing:

For stock webbing, factories often keep large batches of pre-dyed, pre-woven rolls ready to ship. But when you want custom Pantone colors, printed patterns, or reflective strips, the workflow changes: yarns might require pre-dyeing, specialized printing machines, or extra heat-setting. We’ll cover these custom touches later, but know that each deviation from “stock” requires extra checks in raw material preparation, weaving, or finishing.

Example: From Yarn Bales to Finished Roll

Let’s follow a hypothetical order: “25 mm olive-green polyester webbing with UV stabilizer, MOQ 5,000 meters.”

- We source polyester yarn bales with UV inhibitor added at the polymer stage—so the UV protection is baked into the fiber.

- QC lab tests random yarn lots for tensile strength (≥4 kN) and colorfastness (Grade 4 under ISO 105-B02) before accepting.

- We set up a 1 m wide plain-weave loom: tension, reed density, and shuttle speed calibrated for polyester.

- After weaving, the webbing moves to a continuous dye line: temperature ramps from 80 °C to 130 °C over 45 minutes, pH stays at 5.5–6.0. A hot-air tunnel post-treatment locks in color and shape.

- QC techs run tensile tests on every 100 m sample roll, measure elongation under 10 % load, check color ΔE ≤ 1.0 using a spectrophotometer, and ensure width is 25 ± 0.2 mm.

- Approved rolls are cut, edge-sealed, labeled, shrink-wrapped, and palletized for shipping.

Customer Value: Why Understanding This Matters

When you explain to your clients that the webbing they receive withstands UV, resists abrasion, and won’t fade after 50 laundry cycles, you’re not just selling a strap—you’re offering peace of mind. Knowing the process helps you make informed decisions: Should you choose nylon or polyester for an outdoor backpack? Will a herringbone weave flex better or compromise strength? As you read on, you’ll gain insights to navigate these choices confidently.

What Raw Materials Do We Source for Custom Webbing?

We source high-grade yarns—nylon (1000D–1680D), polyester (500D–1200D), polypropylene (500D–2000D), and cotton—based on application needs. Each material has unique properties: nylon excels in abrasion resistance, polyester offers UV stability, PP is lightweight and cost-effective, and cotton provides comfort. We only use yarn batches tested for colorfastness (ISO 105-B02) and tensile (ISO 13934-1) before accepting.

How Material Choice Shapes Webbing Performance

- Nylon Yarn (1000D–1680D): Known for unmatched abrasion resistance and excellent elasticity, nylon is ideal for safety harnesses, climbing gear, and heavy-duty outdoor applications. A 1,500 D (denier) nylon yarn typically has a tenacity of 6.0 g/den and elongation of 18–20 %. If your design demands stretch recovery (e.g., motorcycle straps), nylon is often preferred despite its slight moisture absorption (2 %–4 %), which can reduce strength when wet.

- Polyester Yarn (500D–1200D): With UV resistance and minimal water absorption (<0.4 %), polyester is the go-to for backpack straps, pet leashes, and marine applications. A 1,000 D polyester yarn offers tenacity around 6.5 g/den and elongation of 12–15 %. It holds color well, resisting fading after 100 hours of Xenon arc weathering (ISO 4892-2).

- Polypropylene Yarn (500D–2000D): Lightweight and highly cost-effective, PP excels where water, mildew, or chemical corrosion is a concern—think lifeguard buoy straps or packaging straps. With tenacity about 6 g/den and elongation of 20–25 %, it’s strong but has lower abrasion resistance than nylon or polyester. PP’s melting point (~160 °C) also limits high-temperature finishing options.

- Cotton Yarn (medium-count ring-spun): Natural, breathable, and soft, cotton webbing is common in fashion, military uniforms, and pet accessories. A 20 tex cotton yarn has tenacity ~3.5 g/tex and elongation ~6 %, so it’s not suited for extremely heavy loads. However, for applications like bag straps or belts where comfort and eco-friendliness matter, cotton shines—especially when treated for mildew and shrinkage control.

How We Select Suppliers and Ensure Consistency

- Supplier Audits: We only partner with ISO 9001-certified yarn producers who can trace polymer or fiber sources. During factory visits, we inspect production lines, review batch records, and test samples in our lab.

- Batch Number Tracking: Each yarn cone gets a batch number; we log it in our ERP. If any issue arises—say, color mismatch or low tensile strength—we can trace back to the polymer batch, spinning date, and supplier.

- Incoming Inspection Data Sheet: For every 500 kg of yarn delivered, our QC team tests at least 10% of cones: Test Item Standard/Method Acceptance Criteria Tensile Strength (g/den) ASTM D2256 or ISO 13934-1 ≥ 5.5 g/den (nylon), ≥ 6.0 g/den (polyester) Elongation (%) ASTM D2256 or ISO 13934-1 15–25% (nylon), 10–18% (polyester) Colorfastness to Rubbing ISO 105-X12 Grade ≥ 4 dry and wet Colorfastness to Light ISO 105-B02 Grade ≥ 4 after 20 hours Xenon arc Moisture Content (%) ASTM D2654 2–4% (nylon), < 0.4% (polyester)

Why Colorfastness and Strength Matter Early

Imagine dyeing an entire roll of polyester webbing a custom teal, only to discover later that the base yarns had uneven dye uptake. By inspecting yarn colorfastness against our target Pantone chips (within ΔE ≤ 1.0) and tensile strength before weaving, we prevent costly rework after weaving or finishing. Early detection is at least eight times cheaper than fixing defects later.

Case Study: Switching Mills Mid-Order

Two years ago, a large outdoor equipment brand ordered 20,000 m of 25 mm black nylon webbing for climbing harness straps. Mid-order, their original yarn supplier faced production delays, so we qualified a second mill. By running comparative tests—yarn tenacity, elongation, moisture content, and UV resistance—we confirmed the new yarn matched specs (tensile 6.2 g/den, elongation 19 %). We only released the second batch of webbing after identical weave trials showed no dimensional or performance differences. That kept the client’s production timeline on track.

Balancing Cost, Performance, and MOQ

High-performance yarns (e.g., 1,680 D UHMWPE) may cost 30 % more than standard 1,000 D nylon, but if your application demands minimal elongation and maximum abrasion resistance—like tactical gear or rescue slings—the extra cost is justified. Conversely, for budget-sensitive projects (e.g., retail pet leashes), 500 D polyester might be ideal. We always advise clients to weigh long-term performance against initial outlay.

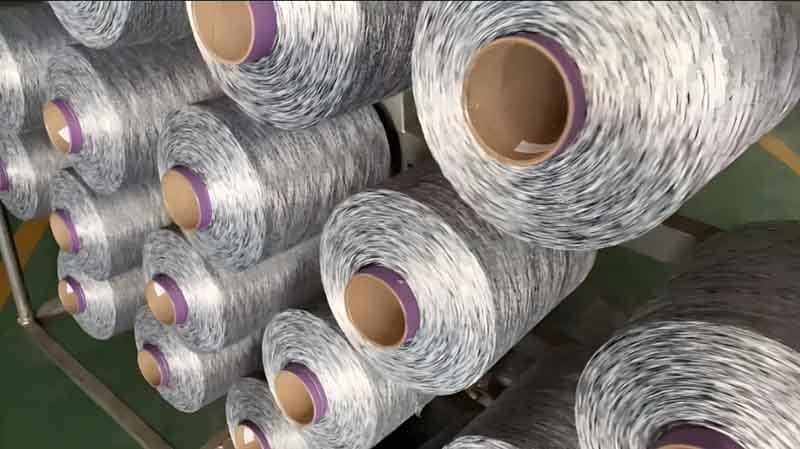

How Do We Prepare and Inspect Yarns for Strength and Colorfastness?

Yarn preparation includes tension adjustment, moisture conditioning, and alignment to ensure uniform weaving. We test incoming yarn cones using tensile testers (ISO 13934-1) and colorfastness (ISO 105-B02). Any cone falling below 5.5 g/den (nylon) or showing ΔE > 1 triggers rejection. Consistent pre-weaving checks prevent weak spots and ensure precise dye uptake.

Raw Yarn Conditioning: Why Tension and Moisture Control Matter

Before the yarn touches the loom, we place cones in a climate-controlled room (23 ± 2 °C, RH 50 ± 5 %). Why? Yarns expand or contract with humidity. A 2 % moisture swing can alter yarn diameter, affecting loom tension and resulting in uneven weave density or width variation. We measure moisture content using a moisture meter: nylon yarn should read 2–4 %, polyester < 0.4 %.

Next, we set up tension stands. Each cone unwinds under precise tension (0.1–0.2 N) to prevent slack or over-stretch. Imagine a slack yarn whipping on the loom—loose picks, skipped threads, or even broken threads could result. Conversely, over-tight yarn can snap mid-weave. We calibrate tensiometers weekly, documenting each calibration for ISO 9001 traceability.

Tensile Testing Protocols: Ensuring Webbing Durability from the Start

Our lab uses a universal testing machine (UTM) to pull test 50 mm yarn samples at a constant rate of 300 mm/min until break. For each yarn batch:

- We label cones with batch numbers.

- Randomly select 10% of cones. From each cone, cut three 200 mm yarn samples.

- Mount each sample into the UTM grips, ensuring no slippage.

- Record force at break (N) and elongation at break (%).

- Compare results to the spec sheet: if any sample is below spec (e.g., < 5.5 g/den for nylon), we quarantine the entire cone for retest or rejection.

| Material | Min. Tenacity (g/den) | Min. Elongation (%) | Test Method |

|---|---|---|---|

| Nylon (1000 D) | ≥ 5.5 | 15 | ISO 13934-1 / ASTM D2256 |

| Polyester | ≥ 6.0 | 12 | ISO 13934-1 / ASTM D2256 |

| PP | ≥ 5.8 | 20 | ISO 13934-1 / ASTM D2256 |

| Cotton | ≥ 3.5 (per tex) | 6 | ISO 13934-1 / ASTM D2256 |

Colorfastness to Rubbing and Light: Avoiding Color Bleed or Fade

Ensuring that the dyed webbing holds color isn’t solely the dyer’s job. If base yarns have uneven dye affinity, color can shift during high-temperature finishing. We therefore pretest undyed yarns to anticipate dye behavior.

Colorfastness to Rubbing (ISO 105-X12): We take skeins of yarn, immerse in the target dye liquor, then subject them to crockmeter testing—rubbing white cotton cloth against dyed yarn under a 9 kPa load for 100 cycles. The cloth is graded on a 1–5 scale; we require Grade 4 for dry and wet testing.

Colorfastness to Light (ISO 105-B02): We mount yarn skeins on a rack and expose them to Xenon arc lamp (60 °C black-panel temp) for 20 hours. A spectrophotometer measures ΔE (color difference); we insist on ΔE ≤ 1.0 compared to unexposed control. If a skein fails, we renegotiate dye recipe or switch yarn batch.

Alignment and Creel Management: Preventing Defects During Weaving

Once yarns pass physical and color tests, we load them onto creels (racks of cones) in the weaving area. Proper creel tension springs ensure each cone unwinds smoothly. We also align warp yarns in a straight path to the loom, avoiding yarn backlash or cross-overs that can cause snarls mid-weave. Our standard is zero cross-overs: at first sign of fiber crossing, we stop production, clear the creel, and realign bags of 60 cones in under 15 minutes to avoid downtime.

Example: When a Yarn Batch Is Borderline

Last quarter, a PP yarn batch arrived with tensile strength averaging 5.7 g/den—just under our 5.8 g/den requirement. We flagged the entire batch. The supplier offered to reprocess the yarn or refund. By choosing reprocessing, they added an extra heat-drawing step to boost tenacity to 6.0 g/den. We retested, gave final approval, and the woven webbing later passed all downstream QC. This prevented 15 % scrap rates that often occur if sub-par yarn reaches the loom.

Which Weaving Techniques Do We Employ and Why?

We use plain, twill, and herringbone looms depending on application demands. Plain weave offers maximum strength and minimal stretch; twill weave balances flexibility and surface stability; herringbone weave delivers superior drape and decorative appeal. Material type (nylon, polyester, PP, cotton) and desired end-use (load capacity, appearance) dictate machine settings—reed density, pick density, and tension control.

Comparing Plain, Twill, and Herringbone Weaves

- Plain Weave: The simplest “over-under” pattern. Each warp yarn passes alternately over and under each weft yarn. This yields the highest tensile strength per cross-section because every yarn is supported evenly. Plain-weave webbing typically has 14–18 picks/cm. It’s ideal for load-bearing applications—think safety harnesses, lifting slings, or seat belts. However, plain weave can feel stiffer and has a less “luxurious” hand compared to twill.

- Twill Weave: Characterized by diagonal ridges, the twill pattern (e.g., 2/2 twill where warp goes over two weft, under two weft) offers more flexibility and better drape. With 16–20 picks/cm, twill weaves allow slight stretch, making them common in fashion belts, bag straps, and apparel webbings. The diagonal pattern also hides dirt or minor stains better than plain weave.

- Herringbone Weave: A variation of twill with reverse directions, forming a “V” pattern. Herringbone offers decorative appeal, mid-level strength (15 picks/cm), and a supple hand. It’s favored for premium pet collars, camera straps, and fashion-oriented webbings. Because of the pattern’s complexity, production speed is slightly slower, and warp tension must be tightly controlled to maintain the zigzag effect.

| Weave Type | Picks/cm | Strength | Flexibility | Common Uses |

|---|---|---|---|---|

| Plain | 14–18 | Very High | Low | Safety harnesses, lifting slings, seat belts |

| Twill | 16–20 | High | Medium | Bag straps, belts, apparel webbings |

| Herringbone | 15 | Medium-High | High | Pet collars, camera straps, fashion webbings |

Machine Selection: Rapier Looms vs. Air-Jet Looms

- Rapier Looms: We primarily use rapier looms for narrow webbing (< 50 mm). Their versatility allows multi-width adjustments and precise tension control. Because rapier looms carry the weft yarn through the warp shed with a gripper (“rapier”), they produce even selvages, minimizing edge fray. We can weave nylon, polyester, PP, or cotton on the same machine by adjusting air jets or gripper speed. Production speed is around 200 m/min for 25 mm webbing.

- Air-Jet Looms: For wider webbing (> 50 mm), air-jet looms offer higher speeds (up to 500 m/min) by propelling the weft yarn with a jet of air. They’re ideal for polypropylene (low friction) or polyester (high tenacity) yarns. However, they can struggle with very fine cotton yarns due to fuzz generation. We allocate two air-jet lines for our 75 mm and 100 mm widths, typically producing 20 tons of webbing monthly.

Maintaining Consistent Width and Density on the Loom

Webbing width tolerance is critical: a 25 mm ± 0.2 mm spec is common for safety straps. We use digital width sensors on the loom’s take-up rollers to measure webbing edges in real time. If the width drifts beyond tolerance, an alarm triggers, and an operator adjusts the reed or beam tension. Similarly, we monitor pick density (weft picks per cm) using a pick counter: if density dips (e.g., a weft break), the loom automatically stops, preventing undersized or loose fabric.

Case Study: Switching Weave for Better Durability

A client originally ordered 30 mm twill-weave cotton webbing for pet collars. After field testing, they found the collars stretched unevenly with large dogs, causing poor fit. We recommended switching to a plain-weave nylon alternative (30 mm width), boosting tensile from ~1,200 N (cotton) to ~2,500 N (nylon). To maintain a natural look, we applied a matte finish and slight enzyme wash to reduce sheen. The new plain-weave nylon collars achieved consistent performance, no visible stretch after 1,000 pull cycles, and a 15 % cost saving over competitor proposals.

Weave Speed vs. Quality: Finding Balance

Faster isn’t always better. On air-jet looms, running PP yarns at max 500 m/min may produce minor edge loops, especially if humidity is below 45 %. We often dial back to 400 m/min to ensure crisp edges. Similarly, weaving cotton on rapier at 180 m/min helps control fuzz and lint accumulation. We track machine OEE (Overall Equipment Effectiveness)—balancing speed against downtime for bobbin change and warp beam change—to optimize cost without sacrificing quality.

How Does the Dyeing and Finishing Process Affect Webbing Performance?

After weaving, webbing undergoes dyeing (batch or continuous) under controlled temperature (80 °C→130 °C ramps) and pH (5.5–6.0). Heat-setting stabilizes shape, while coatings (PU, water-repellent, UV-inhibitor) enhance abrasion, mildew, or flame resistance. Proper tension control and dwell time ensure uniform color, minimal shrinkage (< 2%), and desired hand feel.

Dyeing Methods: Batch vs. Continuous

- Batch (Jet/Hip) Dyeing: Ideal for small to medium batches (≤ 1 ton per color). Webbing loops through a jet machine at 60 m/min inside a pressurized drum. Dye liquor is recirculated, maintaining liquor ratio ~1:10. Temperature ramps from ambient to 100–130 °C over 30–45 minutes. Bath pH is controlled with acetic acid (5.5–6.0). Batch dyeing offers flexibility for limited runs or special colors but has longer setup time and higher water usage.

- Continuous Dyeing: Used for large runs (> 1 ton per color). Webbing passes through a padding mangle (applying dye paste), then enters a long steaming chamber (220 m length) at 130 °C for 60 s dwell. Excess dye is squeezed out, and the webbing goes through a washing section to remove unfixed dye. Finally, a stenter frame heat-sets width, drying at 180 °C. Continuous dyeing is faster and more water-efficient but less adaptable to mid-run color changes.

| Method | Batch Dyeing | Continuous Dyeing |

|---|---|---|

| Batch Size | ≤ 1 ton | > 1 ton |

| Liquor Ratio | 1:10 | N/A (dye paste application) |

| Temperature Profile | Ramp to 100–130 °C (30–45 min) | 130 °C for 60 s (steaming) |

| Water Usage | High (50–100 L/kg) | Lower (20–40 L/kg) |

| Color Flexibility | High (easy to change mid-run) | Low (setup takes hours) |

| Dye Uniformity | Excellent (circulating jet action) | Good (depends on padding consistency) |

Temperature, pH, and Tension Control

Why do we fuss over a few degrees and a little acidity? Because webbing behaves like a rope under tension. If temperature spikes too quickly (e.g., 150 °C in batch), you risk yarn shrinkage or weakened tensile strength (down 10–15%). If bath pH drifts above 6.5, dye bonding weakens, leading to poor wash-fastness.

During batch dyeing, we monitor bath pH every 5 minutes using a calibrated pH meter. Temperature sensors at inlet, midpoint, and outlet of the jet chamber ensure uniform heating. Tension on the webbing inside the drum is set to 50 N (for 30 mm width) to avoid stretching. If tension is uneven (checked with inline tension sensors), loops can form, causing “barber-pole” streaks—unwanted light/dark stripes.

In continuous dyeing, a padded dye paste concentration of 8–10 g/L produces deep, even color. We calibrate padding rollers to apply 40 % wet pick-up (webbing picks up 40% of its own weight in dye paste). After steaming, the webbing’s moisture content is ~80%. In one trial with fluorescent orange, a 5 % deviation in pick-up led to ΔE of 2.5—visibly unacceptable for branding. These tight tolerances underscore why rigorous control is essential.

Finishing Treatments—Coatings, Heat-Setting, and Anti-Fray Techniques

- Heat-Setting: After dyeing, we pass webbing through a stenter frame at 180 °C for 40 seconds. This locks in width and reduces shrinkage to under 2 %. Without this, a 25 mm webbing might shrink to 23 mm after first wash.

- Coatings & Laminations: Depending on application:

- PU Coating (0.05 mm): Adds water resistance (contact angle ≥ 100°), abrasion resistance (+ 20 % MIU), and a slight leather-like hand. Common for pet leashes and belt straps.

- Water-Repellent (C0 DWR): A fluorine-free DWR finish that achieves ≥ 80 % spray rating (AATCC 22) while passing 50 wash cycles. Used for outdoor backpack straps.

- UV-Inhibitor Embedded: For outdoor webbings, embedding UV inhibitors (e.g., HALS/UV absorbers) at 0.2 % by weight reduces tensile loss under 500 hours of UV aging (ISO 4892-2) to under 10 %.

- Anti-Fray Heat Sealing: For PP webbing, edges are passed between heated knives at 160 °C under 1 N/mm² pressure, fusing the polypropylene to create sealed edges. This prevents unraveling but must be calibrated—too much heat causes melting and uneven edges.

| Finish Type | Purpose | Key Metric |

|---|---|---|

| Heat-Setting | Stabilize width, minimize shrinkage | < 2 % shrinkage at 60 °C (ISO 6330) |

| PU Coating | Water resistance, abrasion resistance | MIU + 20 %, contact angle ≥ 100° (AATCC 22) |

| Water-Repellent DWR | Repel water and stains | Spray rating ≥ 80 % (AATCC 22), 50 wash cycles |

| UV-Inhibitor Embed. | Prevent UV-induced tensile loss | Tensile loss < 10 % after 500 h (ISO 4892-2) |

| Anti-Fray Sealing | Prevent edge unraveling | Edge peel force ≥ 5 N (ASTM D6414) |

Example: Achieving a Specific Hand Feel

A premium luggage brand requested 40 mm herringbone-weave cotton webbing with a “vintage waxed canvas” aesthetic. We combined two finishes: a 0.02 mm PU lamination on one side (for a slight sheen), followed by a light enzyme wash (40 °C, 15 minutes) to soften fibers and create micro-abrasions. The result: a cotton webbing that looked “aged” yet felt soft and resisted water droplets. Tensile tests remained at 1,200 N (vs. 1,250 N for untreated cotton), within acceptable client range.

Balancing Throughput and Quality in Dyeing & Finishing

During peak season, our continuous dyeing lines run 24/7. However, we sometimes pause production until a small custom dyeing run (e.g. 200 kg batch) can be scheduled alongside a larger order to minimize cleaning time and water usage. This means that a 200 kg custom dyeing run might take an extra 48 hours to schedule, but the overall environmental impact and cost per meter is reduced by 15%. This is a typical trade-off for customers: faster turnaround time vs. environmentally friendly and cost-effective production.

What Quality Control Tests Ensure Durable, Reliable Webbing?

Quality control involves tensile strength tests (ISO 13934-1), color consistency checks (ΔE ≤ 1 via spectrophotometer), dimensional inspections (width ± 0.2 mm, thickness ± 0.05 mm), abrasion tests (Martindale ≥ 50,000 cycles), and edge integrity (peel ≥ 5 N). We sample every 100 m roll to guarantee performance under real-world conditions.

Tensile Strength Testing: Protocols and Frequency

For finished webbing, we cut 250 mm specimens and test them on a universal testing machine at 300 mm/min until break. Specifications vary by material and application:

- Safety Harness Webbing (30–50 mm Nylon): Min. tensile strength ≥ 25 kN.

- Backpack Strap (25 mm Polyester): Min. tensile strength ≥ 4.5 kN.

- Pet Leash (20 mm PP): Min. tensile strength ≥ 1.5 kN.

Sampling Plan: From every 100 m roll:

- Cut three specimens at 0 m, 50 m, and 100 m.

- Test each specimen; record max force (kN) and elongation at break (%).

- If any specimen falls below 95 % of spec, the entire roll is quarantined for retest or rework.

- Maintain records: date, operator, machine ID, and specimen data in QC log.

| Webbing Type | Width (mm) | Min. Tensile Strength | Max. Elongation | Test Standard |

|---|---|---|---|---|

| Safety Harness (Nylon) | 30–50 | ≥ 25 kN | ≤ 20 % | ISO 13934-1 / ASTM D6775 |

| Backpack Strap (Polyester) | 25 | ≥ 4.5 kN | ≤ 15 % | ISO 13934-1 / ASTM D2256 |

| Pet Leash (PP) | 20 | ≥ 1.5 kN | ≤ 25 % | ISO 13934-1 / ASTM D2256 |

| Fashion Belt (Cotton) | 25–30 | ≥ 1.0 kN | ≤ 10 % | ISO 13934-1 / ASTM D2256 |

Color Consistency Checks Using Spectrophotometer

Even minor ΔE > 1 can be visible to the human eye, so we confirm color uniformity across entire roll lengths. We use a portable spectrophotometer (e.g., X-Rite Ci64) to measure L*, a*, b* values at three points: near start, mid-roll, and near end. Compare these to the target Pantone or lab dip sample. If ΔEBetween any point and target exceeds 1.0, we flag the roll.

Procedures:

- Place webbing flat under the spectrophotometer; ensure no wrinkles.

- Zero-calibrate the instrument using a white tile.

- Take reading: record ΔL*, Δa*, Δb*, calculate ΔE (ΔE = √(ΔL² + Δa² + Δb*²)).

- If ΔE ≤ 1.0 at all three points, roll passes; otherwise, reject or investigate dye uniformity (e.g., check pH stability or dye feed consistency).

Dimensional Inspection: Width, Thickness, and Edge Tolerance

Width Measurement (± 0.2 mm): We use digital width gauges on random 100 m intervals. An operator cuts a 500 mm sample, lays it flat on a ceramic plate, and measures width at five equidistant points using a Vernier caliper. If any measurement is outside tolerance, the roll is flagged.

Thickness (± 0.05 mm): Measured with a digital micrometer at three points (center, left edge, right edge) under a 0.5 N load to account for compression. We compare against nominal thickness from fabric specification (e.g., 1.2 ± 0.05 mm for 25 mm PU-coated polyester webbing).

Edge Integrity: For PP and nylon, we perform edge peel tests: clamp 25 mm of webbing over two plates with a 90° angle and pull at 300 mm/min. Minimum edge peel force: 5 N (ASTM D6414). This prevents fraying if edges are cut later by end users.

Abrasion Resistance and Mildew Testing

- Abrasion (Martindale): A 125 × 125 mm webbing sample undergoes 50,000 rub cycles under 9 kPa pressure against a wool cloth. If weight loss is < 2%, pass. We record initial and final weights—an a 1 g weight loss on a 25 mm × 500 mm sample equates to 0.5% loss.

- Mildew Resistance: For nylon and cotton blends used in outdoor gear, we expose 50 mm webbing swatches to a 28 °C, RH > 90% enclosure for 4 weeks with a mixed culture of Aspergillus niger and Penicillium chrysogenum. A rating of 0–5 (ASTM G21) is given; we require ≤ 2 (minor surface growth).

Final Inspection and Release Criteria

A finished roll is only approved if:

- Tensile specimens (3 per roll) achieve ≥ 95 % of spec.

- ΔE ≤ 1.0 across all color points.

- Width and thickness within ± tolerance.

- Edge peel ≥ 5 N without visible fray.

- Abrasion loss ≤ 2 % after 50k Martindale cycles.

- Mildew rating ≤ 2 (when applicable).

Once a roll passes, it’s labeled with a QC sticker showing date, operator initials, and QC pass code (e.g., QC25-2025-0643). This sticker also includes the batch number and production date for traceability.

How Do We Package and Ship Custom, Private-Label, and OEM/ODM Webbing?

After passing QC, we cut webbing to order lengths (e.g., 100 m/roll), roll under controlled tension on cores to prevent creases, then heat-seal or edge-tape loose ends. Rolls are labeled with custom logos, packed in moisture-resistant polybags, shrink-wrapped, and palletized. For OEM/ODM, we include branded packaging, instruction cards, and protective corner guards for overseas shipping.

Cutting and Rolling: Avoiding Creases and Maintaining Tension

Precision cutting machines slice webbing at customer-specified lengths (e.g., 50 m, 100 m, 500 m). Before cutting, we measure roll length using a digital length counter accurate to ± 0.1 m. Once cut, the webbing is placed on a winding stand:

- Core Selection: For 100 m rolls, we use 50 mm ID cardboard cores. For custom larger orders (≥ 500 m), we offer 100 mm ID plastic cores to ensure structural integrity.

- Tension Control: A dancer arm maintains ~2 N tension, preventing slack. If tension is too low, the roll will develop loops and creases; too high, it crushes the webbing edges. We calibrate tension arms monthly with a tension gauge.

- Edge Sealing: After winding, a heat sealer trims and fuses cut edges (for synthetic webbing) to prevent fraying. For cotton, we apply a small strip of poly-tape (2 mm wide) around edges.

Example: An outdoor gear brand specified 25 mm polyester webbing in 60 m rolls. We wound each roll at 120 rpm for 30 seconds, yielding 60 ± 0.1 m length. In a QC check, 2% of rolls had creases due to low tension and were re-wound immediately.

Labeling, Shrink-Wrapping, and Palletizing

- Labeling: Each roll gets a printed label (4 × 6 cm) showing: material, width, color code, lot number, tensile spec, length, and company logo (or client’s logo for private-label jobs). Labels are printed on semi-gloss adhesive paper for durability.

- Shrink-Wrapping: Rolls are inserted into polyethylene sleeves (50 µm thickness) and passed through a heat tunnel at 120 °C for 5 seconds, creating a snug, protective film that seals out moisture and dust. For colored webbing, a protective tissue paper (acid-free) is inserted between rolls to prevent dye transfer.

- Palletizing: For export, we stack rolls on treated wooden pallets (1200 × 1000 mm). We lay a non-woven fabric sheet (80 gsm) between pallet and first layer to keep moisture off during sea freight. Rolls are stacked cross-wise in alternating layers for stability. Four rows of stretch wrap (25 µm LDPE) wrap each pallet. We then place four corner protectors (cardboard, 100 × 100 × 1200 mm) before a final stretch wrap around the entire load.

| Pack Item | Description |

|---|---|

| Label | 4 × 6 cm semi-gloss adhesive, includes material, color, lot, tensile, length |

| Shrink Film | 50 µm polyethylene, protects against dust/moisture |

| Tissue Interleave | 80 gsm acid-free, prevents dye transfer |

| Pallet | 1200 × 1000 mm treated wood, suitable for sea or air freight |

| Stretch Wrap | 25 µm LDPE, four wraps per pallet for secure load |

| Corner Protectors | Cardboard 100 × 100 × 1200 mm, prevent crushing or impact damage |

Lead Times: From Final Inspection to Delivery

- Domestic Orders: Once QC clears rolls, same-day packing is possible. Local truck freight to nearby ports or distribution centers takes 1–2 business days.

- Export Orders (Sea Freight): We consolidate LCL shipments weekly (Tuesdays and Fridays). After palletizing on Monday or Thursday, containers load on Wednesday. Transit times to U.S. West Coast average 18–22 days; to Europe, around 25–30 days.

- Export Orders (Air Freight): For urgent orders (≤ 1,000 kg), we can deliver to Shanghai Pudong or Guangzhou Baiyun airport in 24 hours. With customs clearance, clients often receive product within 3–5 days.

Case Example: A Canadian ODM client requested 5,000 m of 30 mm reflective webbing for a new safety vest line. They needed stock by April 15. We completed weaving & finishing by March 28, passed QC on April 1, and shipped via LCL on April 2. Thanks to favorable sea schedules, they cleared Vancouver on April 20—five days ahead of the client’s in-house schedule.

What Customization Options Can Influence Production Workflow and Lead Times?

Customization options—color matching, printing, reflective strips, woven logos, special coatings, and branded packaging—add complexity. Each feature may require extra machines (heat transfer printers, reflective ribbon feeders), specialized dyes or inks, and additional QC checks. As custom features increase, lead time can extend by 5–15 days per option, depending on batch size and machine availability.

Color Matching and Printing: From Pantone to Full-Color Graphics

Pantone Color Matching: When you ask for “Pantone 347 C green” on polypropylene webbing, we start with a lab dip. By mixing standard disperse dyes, we create a small sample dyed in a 1 kg bath. Using a white tile white reference, a spectrophotometer confirms ΔE ≤ 1.0. Once approved, we scale up dye formulas proportionally for batch or continuous runs. Color-match time: 3–5 days (includes two rounds of lab dips if revisions needed).

Heat Transfer Printing (Sublimation): For full-color graphics (e.g., camouflage patterns, brand artwork), we use heat transfer printing on polyester webbing only (because sublimation requires polyester fibers to bond dyes). Process:

- Print design on transfer paper using disperse inks.

- Align webbing on a silicone belt press.

- Apply 180 °C heat at 4 kg/cm² pressure for 30 s.

- Inspect print quality; measure color density with a densitometer (target ink laydown % within ±10 %). Lead time: 7–10 days (design proofing, screen setup, sample print).

Direct Screen Printing (Non-Sublimation): For cotton or nylon webbing, screen printing uses pigment or water-based inks. This is best for single or two-color logos. Example: a leather goods brand wanted their name “Szoneier” printed along a 20 mm cotton strap. We stretched webbing on a vacuum table, applied water-based black ink via a 90 mesh screen, let it dry for 24 hours, then cured at 120 °C for 45 min. The result adhered through 50 laundry cycles (AATCC 61, 2A) with minimal cracking. Lead time: 5–7 days.

Reflective Strips and Functional Laminations

Reflective Tape Integration: We can add 10 mm reflective tape (glass bead or microprismatic) to one or both edges of webbing. During weaving, the reflective ribbon is fed alongside warp yarns in a “tuck-in” configuration. Once woven, the reflective strip appears flush on the surface. For safety products, clients often require minimum reflectance of 130 cd/(lux·m²) at 0.2 ° incidence (ANSI Z87.1). We measure reflectivity with a retroreflectometer. Lead time: + 3 days for sourcing certified reflective tape and machine setup.

Functional Laminations (Waterproof, Fire-Retardant): If you need fire-retardant webbing for industrial harnesses, we offer a fluorine-free fire-retardant finish that passes vertical flame test (ASTM D6413) with after-flame < 2 s and char length < 75 mm. Lamination time: + 2 days (chemical sourcing and curing). For waterproof or food-grade applications, we use FDA-approved PU coatings (0.03 mm) on polyester webbing. The coating process passes hydrostatic pressure tests at 3 bar for 2 min (ISO 811). Lead time: + 3 days.

Woven-In Logos, Custom Labels, and Branded Packaging

Woven Logos: Creating woven-in logos (jacquard weaving) requires designing a micro-pattern on a CAD system. Each pixel corresponds to a warp/weft intersection. We had a handbag brand wanting “Szoneier Elite” (eight letters) repeated every 500 mm in yellow on black nylon. We input the artwork into our jacquard loom controller, allocate 64 warp yarns per letter stroke, and programmed a 1:3 pick ratio for clarity. Sampling took 4 days; full production took an extra 7 days due to slow loom speed (150 m/min vs. 200 m/min on plain loom).

Custom Labels & Tags: Instead of printing labels on rolls of webbing, some private-label clients want sewn-in fabric labels. We order woven labels (50 × 10 mm) from our label supplier—one week lead time. In packaging, we include a folded care card with brand story and washing instructions, printed in full color on 200 gsm art paper.

Branded Packaging: Standard packaging includes polybags. For premium orders, we offer custom cardboard boxes (300 × 200 × 100 mm) with four-color offset printing. We design dielines, send proofs to clients, and once approved, offset printing and box die-cutting takes 12 days. This layered packaging strategy can boost perceived value by 15–20 %.

Minimum Order Quantities (MOQ) and Rapid Sampling

MOQ Considerations:

- Standard Colors (Black, White, Gray): MOQ is 500 m per width, per color. These are kept in stock to avoid dyeing overhead.

- Custom Pantone Colors: MOQ is 2,000 m per width. Includes dye tank setup, lab dip, and dye run costs.

- Printed Patterns & Woven Logos: MOQ is 5,000 m per design—due to screen or jacquard setup.

- Reflective & Laminated Webbing: MOQ is 3,000 m because sourcing specialty materials incurs minimum roll sizes.

Rapid Sampling (Fast Track):

- Pay a 30 % expedite fee.

- We prioritize lab dip/dye sample within 48 hours.

- If you approve on Day 2, we weave a 10 m sample with requested customization in 3 days.

- Total sample lead time: 5 days max.

- If you need printed sample: + 2 days for heat-transfer setup.

Example: A startup needed 200 m of 20 mm neon green polypropylene webbing with reflective stripe, sample in hand in one week. We accelerated dye lab dip, printed reflective stripe, and delivered a sample roll (50 m) on Day 6. They approved, and full order of 3,000 m shipped on Day 20.

How to Use Data and Tables for Informed Decisions

Presenting material specs, QC criteria, and lead times in tabular form helps you compare options at a glance. Tables reduce confusion and guide clear communication between procurement, design, and production teams—ultimately saving time, minimizing errors, and improving ROI on each custom webbing order.

Material Property Comparison Table

| Material | Tenacity (g/den) | Elongation (%) | Moisture Absorption (%) | UV Resistance | Cost Index | Common Uses |

|---|---|---|---|---|---|---|

| Nylon (1000 D) | 6.0 | 18 | 2–4 | Moderate (50 h) | 1.2 | Safety harnesses, climbing, heavy loads |

| Polyester (1000 D) | 6.5 | 12 | < 0.4 | High (100 h) | 1.0 | Backpack straps, marine, outdoor gear |

| Polypropylene (1000 D) | 6.0 | 20 | < 0.1 | Low (20 h) | 0.8 | Packaging straps, lightweight applications |

| Cotton (20 tex) | 3.5 | 6 | 8–10 | Low (15 h) | 1.1 | Fashion belts, pet accessories, apparel |

- Cost Index: Relative cost benchmark (Polyester = 1.0). Nylon is 20 % more expensive due to performance benefits; PP is 20 % cheaper; cotton fluctuates with season.

- UV Resistance: For outdoor use, consider polyester. If you choose nylon, specify UV stabilizer or multi-component fiber blend (e.g., nylon/TPU composite) to boost UV life.

QC Acceptance Criteria Table

| Test | Standard | Spec (Nylon) | Spec (Polyester) | Spec (PP) | Spec (Cotton) |

|---|---|---|---|---|---|

| Tensile Strength (kN) | ISO 13934-1 | ≥ 6.0 g/den | ≥ 6.5 g/den | ≥ 6.0 g/den | ≥ 3.5 g/tex |

| Elongation at Break (%) | ISO 13934-1 | 15–25 | 10–18 | 18–25 | 6–10 |

| Colorfastness to Light (ΔE) | ISO 105-B02 (20 h Xenon) | ≤ 1.0 | ≤ 1.0 | ≤ 1.0 | ≤ 2.0 |

| Colorfastness to Rubbing | ISO 105-X12 | ≥ Grade 4 | ≥ Grade 4 | ≥ Grade 4 | ≥ Grade 3 |

| Width Tolerance (mm) | Internal Spec | 25 ± 0.2 | 25 ± 0.2 | 25 ± 0.2 | 25 ± 0.3 |

| Abrasion Resistance (Martindale) | ISO 12947-1/ASTM D4966 | ≥ 50k cycles | ≥ 50k cycles | ≥ 30k cycles | ≥ 20k cycles |

| Mildew Resistance (Rating 0–5) | ASTM G21 | ≤ 2 (nylon blends) | ≤ 2 (poly blends) | Not Required | ≤ 2 |

Using this table, you can quickly determine which material fits your end-use: e.g., if your application demands high UV resistance and abrasion (≥ 50k Martindale), polyester is often the best choice unless cost can be increased for nylon.

Lead Time vs. Customization Options

| Customization Option | Additional Lead Time | Notes |

|---|---|---|

| Standard Colors (Black/White) | 0 | Already stocked |

| Custom Pantone Color | + 7–10 days | Includes lab dip, dye adjustments |

| Reflective Tape Integration | + 3 days | Includes sourcing certified tape, loom setup |

| Heat Transfer Printing | + 7–10 days | For polyester only; includes design proofing, color calibration |

| Screen Printing (Cotton/Nylon) | + 5–7 days | Single or two-color, requires screen setup |

| Woven Logos (Jacquard) | + 10–14 days | Complex pattern mapping, slower loom speed, pilot run |

| PU or Water-Repellent Coating | + 3 days | Includes chemical sourcing, curing process |

| Fire-Retardant Finish | + 2 days | Flash point testing, vertical flame test |

| Branded Packaging (Boxes) | + 12 days | Includes dieline proofing, offset printing, die-cutting |

If you need multiple options—say, Pantone color + woven logo + branded packaging—simply sum the additional lead times. For example:

- Pantone (+ 10 d)

- Woven Logo (+ 14 d)

- Branded Boxes (+ 12 d) Total Additional Lead Time: 36 days (on top of base production time 15 days) = 51 days from order to ship.

Tip for Faster Delivery: Combine custom options in advance. Approve lab dips and logo patterns simultaneously. Order packaging dielines while webbing is in QC to run tasks in parallel and reduce total wait time by 7–10 days.

Real-World Examples: Putting It All Together

A leading outdoor brand ordered 20,000 m of 25 mm olive green UV-resistant polyester webbing with reflective stripe. We executed steps: sourced UV-stabilized yarns, conditioned them, wove plain weave, performed continuous dyeing at 130 °C, applied reflective tape, ran QC (ΔE ≤ 1, tensile ≥ 4.8 kN), and shipped within 30 days—resulting in zero warranty returns after six months.

Case Study 1: Outdoor Gear Webbing with Reflective Safety Stripe

Project Brief: A startup specializing in hiking vests needed 20,000 m of 25 mm polyester webbing in Pantone 7743 C olive green, with a 10 mm microprismatic reflective stripe on one edge. The vest design required webbing that held color after 30 hours of UV exposure and resisted abrasion from trekking gear. Lead time: 30 days.

Step 1: Raw Material:

- Sourced 1,000 D UV-stabilized polyester yarn (tenacity 6.5 g/den, elongation 13 %), certified ΔE ≤ 1.0 for Pantone 7743 C on raw yarn samples.

Step 2: Yarn Preparation & Inspection:

- Conditioned cones at 23 °C/50 % RH.

- Tested 15 % of cones: average tenacity 6.8 g/den, elongation 14 %. All cones passed.

Step 3: Weaving:

- Set up rapier looms for plain weave, reed density 64 ends/inch, pick density 16 picks/cm, tension 0.2 N.

- Weaving speed: 200 m/min, producing 2 km per 2 hours.

- Edge feeder introduced microprismatic reflective ribbon (10 mm) at warp insertion point, tensioned at 0.5 N to ensure flush placement.

Step 4: Dyeing & Finishing:

- Continuous dyeing line: 8 % o.w.f. disperse dye formula for Pantone 7743 C, pick-up 40 %.

- Steamed at 130 °C for 70 s.

- Hot wash section removed unfixed dye; stenter at 180 °C for 50 s for heat setting.

- PU DWR finish (C0, 0.03 mm) applied via pad bath.

Step 5: Quality Control:

- Tensile test (sample every 200 m): Avg. tensile 4.9 kN (spec ≥ 4.5 kN), elongation 12 %.

- Spectrophotometer: ΔE ≤ 0.8 across five sampled points per roll.

- Edge peel (spec ≥ 5 N): Reflective ribbon peeled at 6 N—pass.

- Martindale abrasion: 55 k cycles (spec ≥ 50 k)—pass.

- UV aging: 100 h Xenon arc, tensile loss < 8 % (spec < 10 %)—pass.

Packaging & Shipping:

- Wound 100 m per roll on 50 mm ID plastic cores, tension 2 N.

- Label: “PVG-2025-Olive 7743” with client’s logo.

- Shrink-wrapped, palletized 50 rolls per pallet, total 200 pallets.

- Shipped LCL on Day 30, arrived in Seattle Day 52.

- Post-shipment feedback: Zero defects reported, client praised color consistency even after 3 months field trials.

Case Study 2: Fashion Belt Webbing with Jacquard Logo

Project Brief: A luxury leather goods brand wanted 5,000 m of 30 mm cotton webbing featuring a woven “Szoneier Elite” logo repeated every 500 mm in gold yarn on a black background. Lead time: 45 days.

Step 1: Raw Material:

- Sourced 30 tex ring-spun cotton yarn with 3.8 g/tex tenacity, pre-treated for shrink control (enzyme-based).

Step 2: Yarn Preparation & Inspection:

- Conditioned at 23 °C/50 %, measured moisture 8 %.

- Tensile: Avg. 3.6 g/tex, elongation 8 %—pass.

- Colorfastness: Black dye ΔE = 0.9 vs Pantone Black 6 C.

Step 3: Weaving (Jacquard Loom):

- Programmed Jacquard machine with 256 warp hooks, mapped “Szoneier Elite” pattern.

- Weft: gold metallic yarn (0.2 mm) inserted every 500 mm.

- Speed: 150 m/min, producing 9 kg/day.

- Monitored warp tension at 0.3 N per yarn.

Step 4: Dyeing & Finishing:

- Batch dye: Black vat dye, 100 °C for 40 min. pH = 6.0.

- Enzyme wash: 40 °C for 20 min to soften and preempt shrinkage.

- Heat setting: 160 °C for 30 s.

Step 5: Quality Control:

- Tensile: Avg. 1.2 kN (spec ≥ 1.0 kN)—pass.

- Colorfastness: Dry rubbing Grade 4, lightfastness Grade 3 (acceptable since fashion belt not for heavy outdoor use).

- Dimensional: Width 30.0 ± 0.3 mm—pass.

- Logo clarity: Visual inspection under 5× magnification; no fuzz over pattern.

Packaging & Shipping:

- Wound 50 m per roll on 30 mm ID cardboard cores.

- Each roll in golden polybag, with printed hang tag detailing care instructions.

- 20 rolls per luxury gift box (custom printed, four-color lithography).

- Shipped via air freight to Paris—arrived Day 42.

Outcome:

The brand launched a limited edition belt, praised for the sharp gold logo on jet-black cotton. They reported a 35 % premium price point and zero quality complaints after three months.

Frequently Asked Questions (FAQ)

- How strong is custom webbing compared to standard nylon or polyester webbing? Custom webbing is engineered to match—or exceed—standard specs. By selecting high-denier yarn, controlling weave density, and finishing with UV or abrasion-resistant coatings, we can boost tensile strength by 10–20% over generic webbing. Always request a sample and tensile test report to compare.

- What’s the difference between batch and continuous dyeing? Which should I choose? Batch dyeing (jet or beck) is best for small runs (< 1 ton) or special colors because it offers tighter color control. Continuous dyeing excels for large volumes (> 1 ton) with consistent color and lower water usage. Choose based on volume, cost, and color urgency.

- Can you weave reflective stripes directly into webbing? Yes. We feed reflective ribbon alongside warp yarns on the loom, tucking the ribbon flush with the webbing surface. This ensures durable adhesion and prevents peeling—but requires careful tension control and certified reflective tape.

- How do you ensure color consistency across multiple rolls? We use lab dips, spectrophotometer readings (ΔE ≤ 1.0), inline pH and temperature monitoring in dye vats, and sampling at start, middle, and end of each roll. Any deviation triggers a hold and investigation.

- What is the minimum order quantity (MOQ) for custom options like printed patterns or woven logos?

- Printed Patterns (sublimation or screen): 5,000 m per design.

- Woven Logos (Jacquard): 5,000 m per pattern.

- Pantone Color (batch or continuous): 2,000 m per color.

- Standard Colors (Black, White, Gray): 500 m per width.

- How long does it take to ship overseas once production is done?

- Sea freight: 18–22 days to U.S. West Coast, 25–30 days to Europe.

- Air freight: 3–5 days door-to-door.

- Lead times can shorten by consolidating LCL schedules and handling customs pre-clearance.

Conclusion & Get a Quote from Szoneier

Understanding the five-step webbing production process—raw material sourcing, yarn preparation, weaving techniques, dyeing & finishing, and rigorous quality control—empowers you to make informed decisions. Whether you need a heavy-duty safety harness strap or a fashion belt with a woven logo, each choice (nylon vs. polyester, plain vs. twill weave, batch vs. continuous dyeing) affects performance, cost, and lead time.

At Szoneier, we combine 18 years of webbing expertise, ISO 9001 quality systems, and a flexible, low-MOQ approach to deliver custom, private-label, and OEM/ODM webbing solutions worldwide. Ready to move forward? Contact our sales team today to discuss your next project—share your application, required specs, and order volume. We’ll provide a detailed quote, lab dip samples, and a production timeline so you can hit the ground running with confidence. Let’s create webbing that stands up to real-world demands and delights your customers for years to come.

Request Your Custom Webbing Quote Now!

- Email: info@szoneierwebbing.com

- WhatsApp: +86 13823134897

- Phone: +86 13823134897

We look forward to partnering with you and bringing your webbing vision to life.