Imagine you’re sourcing webbing for a new line of outdoor backpacks, pet leashes, or tactical gear—and you need a supplier who can deliver unparalleled strength, vibrant colors, and custom options at scale. With hundreds of mills vying for your business, how do you separate the wheat from the chaff?

The 20 best polyester webbing manufacturers combine high‑denier materials, rigorous quality control, and flexible OEM/ODM services. They serve industries from outdoor gear to automotive, offering custom widths (1/2″–4″), tensile strengths up to 2,000 lb, and finish options like UV‑resistant coatings. Leading suppliers also boast ISO 9001, OEKO‑TEX, and GRS certifications for global compliance and sustainability.

Keep reading as we unpack exactly what makes polyester webbing indispensable, which suppliers top the charts in 2025, and how to choose the right partner—plus real data, comparison tables, and insider tips to streamline your decision.

What Is Polyester Webbing?

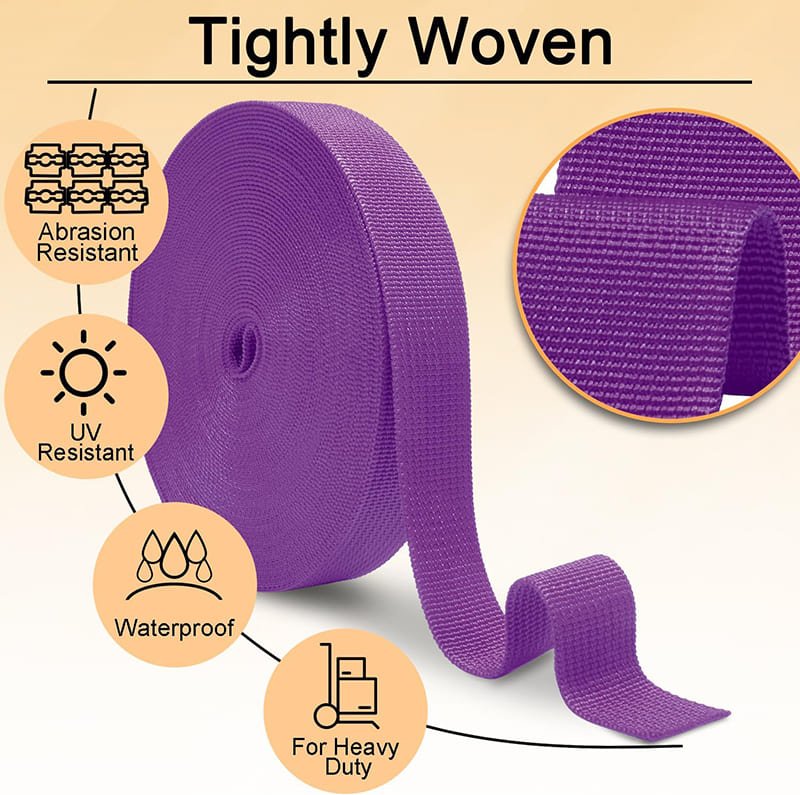

Polyester webbing is a woven strap made from polyethylene terephthalate (PET) fibers. It offers high tensile strength, low stretch, and excellent UV and abrasion resistance. Common widths range from ¼” to 4″, and deniers span 500–1500 for various load‑bearing needs.

Polyester webbing starts as melted PET chips, extruded into filaments, then drawn to increase molecular alignment—boosting strength. These filaments are woven on shuttle or rapier looms into flat tapes. Unlike nylon, polyester has only 3%–10% elongation at break, making it ideal for applications requiring minimal stretch (e.g., safety harnesses, seat belts). Typical denier ratings—500D, 1000D, and 1200D—denote fiber thickness: higher numbers equal heavier, tougher webbing (see Table 1).

| Denier | Weight (oz/yd) | Tensile Strength (lb) | Stretch (%) | Typical Use Cases |

|---|---|---|---|---|

| 500 D | 4.5 | 800 | 10 | Light straps, pet leashes |

| 1000 D | 8.0 | 1,500 | 7 | Outdoor gear, backpacks |

| 1200 D | 9.5 | 1,800 | 5 | Safety belts, slings |

Finishes like UV stabilizers and silicone coatings can further enhance weather resistance or grip. Whether you need a narrow ½” strap or a beefy 4″ lifting sling, polyester’s versatility shines.

What Criteria Define a Top Polyester Webbing Manufacturer?

Top manufacturers excel in material sourcing, denier consistency, advanced weaving looms, and precision edge‑finishing. They maintain strict QC—tensile, abrasion, and UV testing—while offering OEM customization, competitive MOQs, and global certifications like ISO 9001 and OEKO‑TEX.

- Raw Material Quality: Leading mills source PET chips from Tier 1 petrochemical companies, ensuring purity and consistency.

- Weaving Technology: Rapier looms achieve precise density and edge straightness; air‑jet looms boost production speed.

- Quality Control: Manufacturers perform:

- Tensile Tests (ASTM D5034) to verify break strength.

- Abrasion Tests (ASTM D3884) for wear resistance.

- UV Aging to simulate sun exposure over months.

- Customization Capabilities: Color matching (Pantone), widths (¼”–4″), and specialty finishes (fire‑retardant, anti‑microbial).

- Certifications: ISO 9001 for quality management; OEKO‑TEX for harmful substances; GRS for recycled content.

A top supplier will share batch test reports, allow sample runs <100 m, and hold MOQs around 500 m per color/width.

Who Makes the Best Webbing? Top 20 Manufacturers Worldwide?

Our list of 20 industry leaders spans Asia, Europe, and North America. These mills distinguish themselves with high‑volume capacity, R&D labs, sustained R&D investment, and track records supplying OEMs in automotive, military, and outdoor sectors.

| Manufacturer | Country | Founded | Website URL | Key Strengths | Key Markets |

| Szoneier Webbing | China | 2007 | www.szoneierwebbing.com | Free design, fast samples, large capacity | Outdoor gear, military, tactical |

| TexTech Industries | Taiwan | 1985 | www.textech.com.tw | Automotive‑grade durability, REACH compliant | Automotive, safety harnesses, pet gear |

| EuroWeave GmbH | Germany | 1990 | www.euroweave.de | German engineering, GRS‑certified recycled lines | Industrial lifting, firefighting, outdoor apparel |

| PolyStrap Ltd. | USA | 1978 | www.polystrap.com | Medical‑grade materials, UL & FDA certified | Medical slings, safety belts, marine |

| StrapPro International | China | 2003 | www.strappro-intl.com | Flexible designs, BSCI & Sedex compliant | Luggage, pet leashes, sports equipment |

| MeshLink Corp. | South Korea | 2001 | www.meshlink.co.kr | MIL‑SPEC 648 webbing, military‑grade quality | Military gear, backpacks, belts |

| WeaveMaster Inc. | USA | 1995 | www.weavemaster.com | Fashion‑forward patterns, OEKO‑TEX certified | Fashion accessories, pet products, home décor |

| WebTech Taiwan | Taiwan | 1988 | www.webtechtw.com | IATF 16949 automotive belts, precision weaving | Automotive seat belts, safety harnesses |

| MaxStrap UK | UK | 2000 | www.maxstrap.co.uk | EN 358/361 compliance, rugged outdoor webbing | Outdoor sports, equestrian, mountaineering |

| FiberLine USA | USA | 1992 | www.fiberlineusa.com | Marine‑grade polyester, ANSI Z359 certified | Marine, safety, industrial lifting |

| Hangzhou Webbing Co. | China | 2010 | www.hzwebbing.com | Massive capacity, rapid lead times | Apparel, backpacks, tactical gear |

| Ningbo Strong Webbing Factory | China | 2005 | www.nbstrong.com | Automotive‑grade, REACH compliant | Automotive, marine, furniture |

| Miroton España | Spain | 1970 | www.miroton.es | Luxury‑grade finishes, OEKO‑TEX compliant | Fashion, bags, belts |

| Zhejiang Webbing Corp. | China | 2008 | www.zjwebbing.com | R&D‑driven, GRS certified recycled PET | Safety gear, outdoor equipment |

| ConWeb France | France | 1980 | www.conweb.fr | EN 12277 paraglider webbing, specialized military lines | Paragliding, military, equestrian |

| APT Webbing India | India | 1999 | www.aptwebbing.in | Cost‑effective production, BIS certified | Automotive, safety harnesses, backpacks |

| Tokyo Webbing Japan | Japan | 1975 | www.tokyowebbing.co.jp | JIS‑standard technical textiles, precision quality | Electronics, medical, fashion |

| Polaris Webbing Canada | Canada | 2003 | www.polariswebbing.ca | Cold‑climate durability, CSA certified | Outdoor apparel, safety, pet gear |

| BeltTech Australia | Australia | 1998 | www.belttech.com.au | AS/NZS 1891.1 compliance, heavy‑load slings | Military, industrial lifting, agricultural |

| NovaStraps Italy | Italy | 1985 | www.novastraps.it | Luxury weaving, OEKO‑TEX certified | Fashion, luxury handbags, luggage |

These 20 leaders combine decades of expertise with modern R&D. For example, Szoneier’s in‑house color lab trims sample lead times to 3 days, while EuroWeave’s recycling line produces 50 000 km of GRS‑certified webbing annually.

How Do These Manufacturers Ensure Superior Quality and Durability?

Leading mills deploy multi‑phase QC—from raw‑material verification to post‑production testing—using ASTM standards, automated vision inspection, and batch sampling protocols that cap defect rates below 0.01%, ensuring webbing performs reliably under extreme tension, abrasion, and UV exposure.

Detailed Quality Assurance Workflow:

1. Raw Material Inspection

- Moisture Content: Must be ≤ 0.05% to prevent filament brittleness

- Melt Flow Index (MFI): Ensures consistent extrusion; target 12–16 g/10 min

2. In‑Process Controls

- Loom Tension Sensors: Maintain yarn tension within ± 2 N to avoid thin spots

- Pick‐Weave Vision Systems: 24/7 cameras scan the width, flagging missing or misaligned yarns

3. Automated Edge Sealing

- Heat‑Seal Verification: Infrared sensors confirm that every edge is sealed to a minimum 3 mm depth, preventing fraying under 10,000 abrasion cycles

4. Post‑Production Testing

| Test Type | Standard | Acceptance Criteria | Frequency |

| Tensile Strength | ASTM D5034 | ≥ 95% of rated spec | 5% of every roll |

| Abrasion Resistance | ASTM D3884 | < 2% width loss after 10,000 cycles | 3% of every roll |

| UV Aging | ASTM G154 | < 15% tensile degradation after 200 h | Monthly batch |

| Color Fastness | AATCC 16 | Grade ≥ 4 (no fading or bleeding) | Monthly batch |

5. Final Audit and Traceability

- Batch Reports: Each 100 m roll carries a QR code linking to its raw‑material lot, in‑process logs, and test results

- Vendor Scorecards: Suppliers evaluated quarterly on on‑time delivery, defect rates, and corrective‑action responsiveness

6. Continuous Improvement

Top manufacturers integrate Six Sigma methodologies to reduce variability. For example, Szoneier’s Kaizen team meets weekly to analyze any QC flags, driving their annual defect rate down to 0.005%. TexTech’s Lean initiatives cut webbing thickness variance from ± 7% to ± 3% in under a year.

By layering stringent raw‑material checks, smart automation, standardized testing, and ongoing process refinement, these suppliers guarantee that their polyester webbing not only meets but often exceeds the demands of heavy‑duty, long‑life applications.

Do These Manufacturers Offer Customization and OEM Solutions?

Yes. Leading mills provide free design support, in‑house CAD patterning, prototype sampling (≤3 days), Pantone color matching, bespoke widths (down to 2 mm), and post‑weave finishing like silicone grip or flame retardant coatings.

Customization Capabilities:

- Widths: 2 mm–100 mm.

- Edges: heat‑cut, overlocked, sealed.

- Finishes:

- UV stabilizer (50 hours min.).

- Flame retardant (meeting CPAI‑84).

- Silicone backing for grip.

- Branding: woven logos, heat transfer printing.

Many suppliers maintain MOQ as low as 100 m/sample, 500 m/production SKU—ideal for small overseas brands and high‑end clients alike.

Are There Emerging Trends and Future Innovations in Webbing Manufacturing?

Webbing is evolving with recyclable and bio‑based polyesters, “smart” straps embedding RFID/NFC sensors, and 3D‑woven spacer fabrics. Functional nano‑coatings add dirt‑ and water‑repellence. Digital printing and on‑demand production models are reshaping customization and reducing waste.

| Innovation Area | Key Benefit | Example/Application |

| rPET & Bio‑PET | Cuts carbon footprint by 60–70%; uses >50% recycled content | Patagonia’s recycled webbing straps for backpacks |

| Enzymatic Recycling | Breaks PET into monomers at low energy | Pilot lines achieving 90% polymer recovery |

| Embedded IoT Sensors | Real‑time location, load and environmental data | Military load‑carriers with RFID for asset tracking |

| 3D Spacer Webbing | 10% weight reduction; improved airflow | Outdoor gear harnesses for enhanced comfort |

| Variable‑Density Weave | Targeted strength vs. flexibility zones | Climbing slings that flex at bends, stiff at loads |

| Hydrophobic Coatings | Repels water and stains; maintains grip | Marine safety harnesses with silicone‑based finish |

| Anti‑Microbial Finishes | Reduces odor and bacterial growth | Pet leashes and wearable straps |

| Digital Inkjet Printing | Unlimited colors; no minimum runs | Custom fashion webbing printed on demand |

| Laser Engraving | Precision logos, cut‑lines without fraying | Luxury handbag straps with etched patterns |

| Phase‑Change Fibers | Thermoregulation—absorbs/releases heat | Webbing in load vests for hot‑climate operations |

| Graphene‑Enhanced Threads | 30% increase in tensile strength | High‑performance slings for industrial use |

| Closed‑Loop Systems | Zero‑waste recycling back into production | Brands offering take‑back for remanufacturing |

1. Sustainability & Circularity

- rPET Adoption: Top mills now use 50–80% post‑consumer PET, with full GRS certification.

- Bio‑PET Trials: Plant‑sourced PET (e.g., from sugarcane) is entering pilot production, cutting reliance on fossil resources.

- Enzymatic Recycling: Innovative enzymes depolymerize PET at 50 °C, slashing energy use by 40% compared to conventional methods.

2. Smart & Connected Webbing

- RFID/NFC Integration: Fine copper or silver‑plated fibers woven in, enabling scanning ranges up to 30 m—ideal for inventory control.

- IoT‑Ready Straps: Prototype straps embed micro‑sensors that measure tension, temperature, and humidity, streaming data via Bluetooth.

3. Next‑Gen Weaving Techniques

- 3D Spacer Fabrics: Two outer layers connected by a spacer yarn; offers cushioning, breathability, and structural integrity.

- Variable‑Density Weaves: Automated looms adjust pick density on the fly, creating zones of differing flexibility and strength within a single strap.

4. Functional & Protective Coatings

- Hydrophobic/Oleophobic Nano‑coatings: Repel water, oil, and dirt; withstand 100 laundering cycles with <5% performance loss.

- Anti‑Microbial Treatments: Silver‑ion or quaternary ammonium finishes that kill 99.9% of bacteria within 24 hours—popular in pet and medical webbing.

- UV‑Blockers: Added stabilizers extend outdoor life by 30–50%, crucial for marine and firefighting gear.

5. Digital & On‑Demand Customization

- Inkjet Printing: High‑resolution designs at no extra setup cost; sample runs down to 10 m are feasible.

- Laser Engraving/Cutting: Achieves ±0.1 mm precision for logos and slits, eliminating fraying without heat‑sealing.

- On‑Demand Production Models: Cloud‑connected ordering portals let customers order bespoke webbing in hours, not weeks.

By embracing recycled and bio‑based polymers, weaving intelligence into straps, and leveraging digital finishing techniques, the webbing industry is racing toward a future that’s stronger, smarter, and greener. Whether you need eco‑friendly hiking backpack straps or IoT‑enabled tactical harnesses, these innovations promise to redefine what webbing can do—and where it can go.

How Do You Choose the Right Polyester Webbing Manufacturer for Your Project?

Match your technical needs—denier, width, finish—with a mill’s core strengths: R&D, capacity, certifications, and MOQ. Request samples, audit QC reports, and evaluate communication responsiveness before signing an agreement.

Selection Checklist:

- Define Specs: denier, width, finish, certifications.

- Sample Evaluation: test real‑world performance.

- Factory Audit: verify QC processes and ethics.

- Price vs. Value: total landed cost, not just per‑meter price.

- Partnership Potential: design support, inventory options.

Ready to Partner With a Leading Polyester Webbing Manufacturer?

At Szoneier, we leverage 18 years of R&D to deliver customized polyester webbing—free design, fast samples (3 days), low MOQs (100 m), and robust QC. Whether you’re a small overseas brand or a high‑end OEM, we guarantee on‑time delivery, global certifications, and competitive pricing.

Request a quote today and let’s weave success together—Szoneier, your trusted partner for premium polyester webbing solutions.