Ever tried hauling a load only to have it shift, bang, or even fall off mid-journey? Ratchet straps are the unsung heroes that keep your cargo locked down tight.

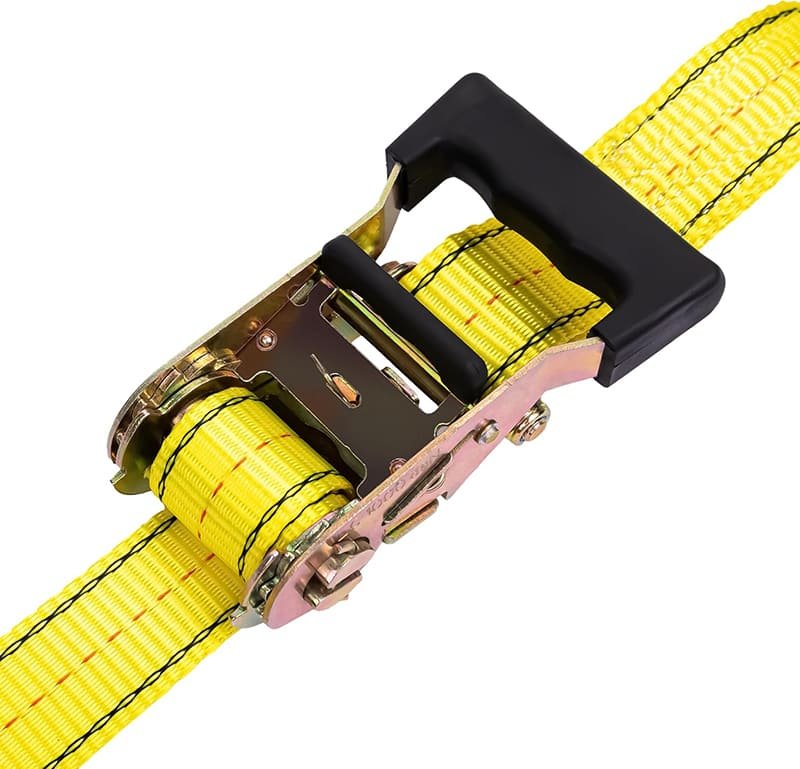

A ratchet strap combines rugged polyester webbing and a gear‑and‑pawl ratchet mechanism to deliver up to 3,000 lbs of clamping force. Simply feed the strap, crank the ratchet handle, and lock it in place. It’s that easy to turn wobbling loads into rock‑solid security, whether you’re moving a motorcycle, piling on lumber, or shipping heavy machinery.

Let me tell you about my buddy Joe, who once loaded his vintage Ducati onto a trailer with nothing but bungee cords—big mistake. That baby slid forward on the highway, nearly sending him off the road. After switching to ratchet straps, he’s a believer: no fuss, no drama, just peace of mind. Ready to dive deep? Let’s go!

What are Ratchet Straps and How do They Work?

Ratchet straps use durable polyester webbing wrapped around a toothed drum. Cranking the ratchet handle pulls the webbing tight, and a pawl locks the teeth—giving you mechanical advantage and vibration‑proof tension.

Mechanical Advantage & Gear Ratios

- Gear Ratio: Most ratchets use a 4:1 or 5:1 ratio. That means one full handle crank multiplies your hand force by 4–5 times.

- Force Calculation: If you apply 50 lbs of hand force, a 5:1 ratchet generates ~250 lbs of tension per crank.

- Wind‑Up Efficiency: Typical ratchets pull in 1 ft of webbing per 3–5 handle strokes.

Webbing Stretch & Load Stability

- Polyester Elongation: Under load, polyester stretches only ~5–7%, whereas nylon can stretch 20–30%. Lower stretch = less “bounce” on bumpy roads.

- Vibration Lock‑In: The pawl design prevents any backward movement, crucial for long hauls.

Real‑World Example: Moving a Motorcycle

- Initial Wrap: Loop the strap around the fork tubes and frame crossbar.

- Hand‑Pull Tight: Remove slack manually.

- Crank the Ratchet: 8–10 strokes until the bike is immobile.

- Lock & Tuck: Close the ratchet, tie off excess webbing.

When Over‑Tightening Backfires

- Frame Stress: Too much tension can bend handlebars or fork tubes.

- Cargo Damage: Wooden pallets or fragile crates might crack under extreme force.

- Tip: Aim for firm but not bone‑crushing tension—about 20–30 lbs of residual hand‑pulling force.

Who Needs Ratchet Straps?

From DIY movers to commercial fleets, anyone transporting gear outdoors—motorcycles, furniture, landscaping supplies, or heavy machinery—relies on ratchet straps for safe, worry‑free hauling.

DIY Home Movers

- Furniture & Appliances: 2″ × 15 ft straps with 3,333 lbs WLL (Working Load Limit) are common.

- Common Mistake: Using too‑short straps → insufficient wrap → load shift.

Construction & Landscaping

- Lumber Bundles: 3″ × 20 ft straps with 5,000 lbs WLL.

- Equipment: Compact loaders, generators—often need 4″ × 30 ft straps (8,000 lbs WLL).

- Weatherproofing: UV‑coated webbing lasts 2–3× longer in sun exposure.

Commercial Trucking Fleets

- Regulations: FMCSA mandates securement for all flatbed loads, with a minimum of two straps per 10 ft of cargo length.

Adventure Enthusiasts

- Roof Racks & Trailers: Kayaks, canoes—1″ × 10 ft straps (WLL 800 lbs).

- Off‑Road Vibration: Spring‑loaded rewind straps reduce flapping webbing noise.

| User Type | Strap Size | Typical WLL | Use Case |

|---|---|---|---|

| Home Movers | 2″ × 15 ft | 3,333 lbs | Sofa, fridge |

| Construction | 3″ × 20 ft | 5,000 lbs | Lumber, pipes |

| Heavy Equipment | 4″ × 30 ft | 8,000 lbs | Generators, skid loaders |

| Outdoor Enthusiasts | 1″ × 10 ft | 800 lbs | Kayaks, bikes |

Which Materials and Components Make up a Ratchet Strap?

Ratchet straps pair UV‑stable polyester webbing (breaking strength up to 15,000 lbs) with zinc‑plated or powder‑coated steel ratchets and forged steel hooks—designed to resist abrasion, corrosion, and weather.

Webbing Material Comparison

| Material | Tensile Strength | Elongation | UV Resistance | Typical WLL Range |

|---|---|---|---|---|

| Polyester | 6,000–15,000 lbs | 5–7% | Excellent | 1,000–8,333 lbs |

| Nylon | 8,000–16,000 lbs | 20–30% | Good | 1,333–5,000 lbs |

| Polypropylene | 4,000–10,000 lbs | 10–15% | Fair | 800–3,333 lbs |

- Why Polyester? Low stretch + high UV/abrasion resistance = stable loads.

- Polypropylene Trade‑Offs: Cheaper, lighter, but weaker in sun.

Ratchet Mechanism Specs

| Component | Material | Key Spec |

|---|---|---|

| Frame & Handle | High‑carbon steel | 3:1, 4:1, 5:1 gear ratios |

| Pawl | Heat‑treated steel | 0.18″ thickness |

| Spring | Stainless steel | Corrosion‑proof coil |

| Finish | Zinc or powder coat | 25–35 µm thickness |

Hook & Fitting Varieties

- S‑Hooks: Quick‑attach, open style.

- Snap Hooks: Spring‑loaded latch for secure fit.

- Flat J‑Hooks: Sit flush on flat anchor points.

- E‑Track Fittings: Slide into standard E‑track rails.

Tip: Match hook type to your anchor points to prevent slippage and webbing wear.

What is the Difference Between Ratchet Straps and Tie‑down Straps?

Ratchet straps deliver higher tension (>3,000 lbs) via gear mechanisms, while cam‑buckle tie‑downs offer quick, tool‑free tensioning up to ~1,500 lbs—ideal for lighter loads or frequent loading/unloading.

| Feature | Ratchet Straps | Cam‑Buckle Straps |

|---|---|---|

| Maximum WLL | 1,000–8,333 lbs | 500–1,500 lbs |

| Tension Method | Gear‑and‑pawl ratchet | Lever cam buckle |

| Tension Speed | 5–10 crank strokes/ft | 1–2 lever squeezes/ft |

| Lock‑in Security | Excellent (no back‑drift) | Moderate (slight slip) |

| Ideal Use Case | Heavy machinery, pallets | Kayaks, lawnmowers |

| Typical Price Range | $12–$25 per strap | $5–$12 per strap |

- Why Choose Cam‑Buckle? Fast, fuss‑free for light gear.

- When Ratchets Win: Long‑haul trucking, construction, motorcycle transport.

What is the Nickname for a Ratchet Strap?

In the field, people call them “ratchet tie‑downs,” “ratch straps,” or just “ratchets.”

- U.S. Usage: “Ratchet straps” or “ratchet tie‑downs.”

- U.K./Australia: “Load binders” or “ratchet load straps.”

- Industry Slang:

- “Ratch straps” on loading docks.

- “Handle straps” among rental gear techs.

- Marketing Spin: Brand‑specific names like “CargoGrip™” or “LockDown™.”

Who do Americans Call Ratchet Straps?

Most Americans simply say “ratchet straps” or “ratchet tie‑downs.” Some truckers abbreviate to “ratchets,” while gearheads might call them “ratch straps.”

What is the Purpose of a Ratchet?

The ratchet lever multiplies your hand force via a gear‑and‑pawl system, pulling webbing tight and locking it securely—essential for clamping heavy loads with minimal effort.

- Gear Ratio Impact:

- A 5:1 ratio means 5 lbs hand force = 25 lbs tension.

- More teeth on the drum = smaller incremental tension gains per stroke.

- Spring‑Loaded Pawl:

- Prevents reverse rotation, keeping tension locked under vibration.

- Regular lubrication (light oil) extends life.

- Modern Innovations:

- Battery‑powered tensioners in industrial settings.

- Pneumatic binders for ultra‑heavy lifting.

How do You Choose the Right Ratchet Strap for Your Load?

Pick straps with WLL ≥ 50% of your cargo weight, webbing width suited to your load type, strap length matching anchor spacing, and hook style compatible with your anchor points.

Calculating WLL & BS

- Industry Rule: Breaking Strength (BS) = WLL × 3.

- Example: 3,000 lbs WLL → BS = 9,000 lbs.

Strap Size Recommendations

| Load Type | Strap Size | WLL | BS |

|---|---|---|---|

| Light patio set | 1″ × 10 ft | 800 lbs | 2,400 lbs |

| Mid‑weight motorcycle | 2″ × 15 ft | 3,333 lbs | 10,000 lbs |

| Heavy equip. trailer | 4″ × 30 ft | 8,000 lbs | 24,000 lbs |

| Lumber bundles | 3″ × 20 ft | 5,000 lbs | 15,000 lbs |

Length & Wrap Factor

- Anchor Distance + 2 ft: Ensures you can wrap around bars or frames for extra security.

- Wrap‑Around Method: Webbing looped around one side of object → anchor point → back around → ratchet.

Hook Compatibility

- Flat vs. Curved Hooks: Flat reduce roll, curved fit round bars.

- E‑Track Fittings: Slide‑in for standardized racks.

How do You Properly Use and Tension a Ratchet Strap?

Thread webbing through the mandrel, remove slack by hand, crank the ratchet handle until the load is snug, lock the lever, and tie off excess. Release by pulling the release tab, opening the handle fully, and rewinding the strap.

- Inspection First

- Webbing: No cuts, UV brittleness, or frays.

- Ratchet: Gear teeth intact, pawl spring intact.

- Threading

- Feed strap straight through the mandrel.

- Avoid twists to ensure even tension.

- Hand‑Tighten

- Pull webbing by hand to remove major slack (about 10 – 20 lbs force).

- Ratchet Cranks

- 6–10 full strokes for light loads; 12–20 for heavy.

- Stop when webbing stops expanding under pressure.

- Lock Position

- Close handle fully; snap into lock position.

- Tie off loose strap tail with a half‑hitch knot.

- Safe Release

- Wear gloves to protect from pinch points.

- Pull release tab, open handle all the way, let webbing unwind.

- Storage & Care

- Hang straps in dry area, away from direct sunlight.

- Lubricate pivot and spring annually.

Conclusion & Call to Action

Ratchet straps turn transport chaos into confidence. Whether you’re a DIY mover, construction pro, fleet manager, or weekend adventurer, these simple tools fasten your gear securely—every time.

Ready to upgrade? At Szoneier, we customize ratchet straps with your logo, offer free design mockups, and provide samples at no charge. Let’s make your next shipment the smoothest yet—contact us today for a personalized quote!