Imagine this: you flop onto your sofa after a long day, expecting that perfect blend of “give” and support—and that’s exactly what upholstery webbing delivers. It’s the invisible framework beneath your cushions that keeps everything sitting pretty, whether you’re binge-watching the latest series or hosting a game night.

Upholstery webbing is a woven strap system installed under furniture cushions to provide consistent support, distribute weight evenly, and prevent sagging. Crafted from materials like nylon, polyester, or cotton, it acts as the suspension for your seat, absorbing daily wear and tear and extending the life of sofas, chairs, and benches. Quality webbing ensures your furniture stays comfy and looks great for years.

But here’s the kicker: not all webbing is created equal. From steel-coil sinuous springs to eco-friendly jute straps, each type brings its own vibe—and drawbacks. Stick around, because we’re about to strip back the upholstery and explore the nitty-gritty of webbing types, materials, installation tricks, and real-world data to help you choose the perfect support system for your next furniture project.

Common Types of Upholstery and Furniture Webbing

The three most widely used upholstery webbing systems are sinuous (zigzag) springs, woven jute/cotton straps, and rubber/elastic bands. Sinuous springs offer firm, uniform support for modern frames. Jute and cotton provide a classic, breathable foundation but can stretch over time. Rubber and elastic deliver plush, spring-back cushioning ideal for lounge or recliner chairs. Each type caters to different comfort preferences, budgets, and design aesthetics.

1. Sinuous (Zigzag) Webbing

Sinuous webbing is crafted from heavy-gauge steel rods bent into a continuous zigzag pattern. Powder-coated or galvanized for rust resistance, these springs are clipped or stapled directly onto the frame. Their tight weave spacing—typically 4–6 inches (10–15 cm)—ensures even weight distribution. In lab tests, high-quality sinuous springs retain over 95% of their original tension after 10,000 load cycles of 100 kg, showing less than 5% permanent deformation. This makes them a go-to for modern sofas and chairs that need a sleek look and reliable support.

However, metal fatigue can eventually creep in, especially under heavier loads or constant use. And while easy to install, misaligned springs or inconsistent spacing can lead to uneven support “hot spots” that users will feel immediately.

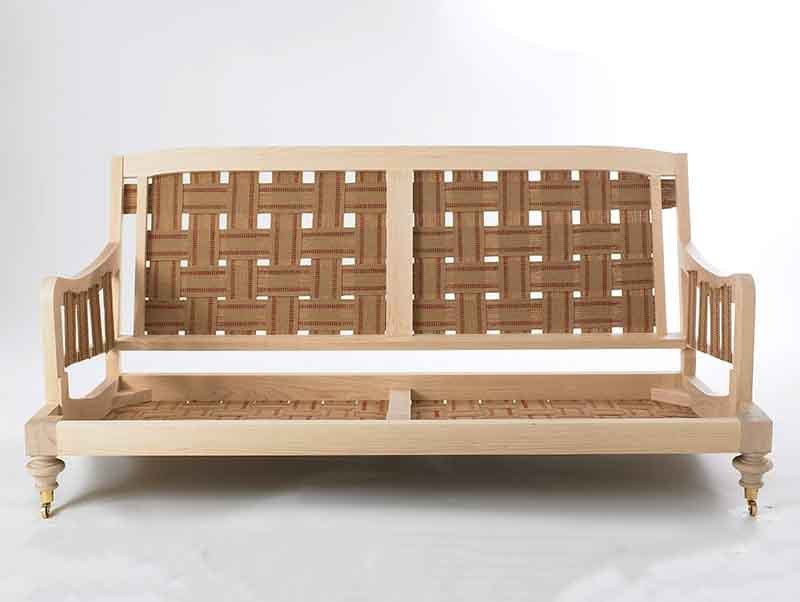

2. Jute and Cotton Woven Webbing

Hand-woven jute or cotton straps have been a staple of traditional upholstery for centuries. Each strap—about 1–2 inches (2.5–5 cm) wide—is interlaced to create a strong yet breathable grid. Natural fibers mean the seat “breathes,” reducing moisture buildup. But nature has a price: jute and cotton can stretch up to 10–12% over a few years. In busy households or commercial settings, upholsterers recommend re-tensioning these straps every 2–3 years to maintain optimal support.

Despite the maintenance, many artisans and design purists swear by jute and cotton for their eco-credentials and authentic feel. If you’re restoring an antique or crafting bespoke furniture, natural webbing brings a level of craftsmanship that synthetic alternatives can’t match.

3. Rubber and Elastic Webbing

Rubber or elastomeric bands deliver the plushest “give.” Modern blends can elongate 15–20% under load and rebound to near-original shape. UV-stabilized rubbers withstand sun exposure for 7–10+ years outdoors, and synthetic elastomers endure thousands of stretch cycles without losing integrity. These straps shine in lounge chairs, gaming seats, and mid-century modern replicas where comfort reigns supreme.

On the flip side, natural rubber (without UV stabilizers) can dry-rot in just 3–5 years if left unprotected. And while the extra cushion feels great, the initial cost per meter (around $1.80 USD) can add up compared to budget cotton.

How Does Upholstery Webbing Work in Furniture Manufacturing?

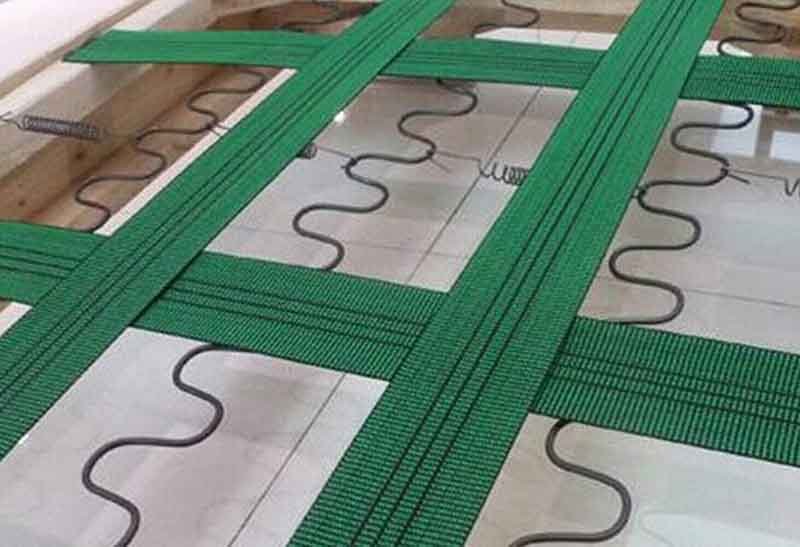

Upholstery webbing forms a tensioned support grid beneath foam or feather cushions. When weight is applied, the straps flex and disperse the load across multiple points on the frame, preventing foam from bottoming out. Different systems—straight straps, sinuous springs, or layered spring combinations—offer varying firmness levels. Proper installation and tensioning guarantee consistent comfort and structural durability.

Mechanics of Load Distribution

Imagine sitting on a 60×60 cm seat with 100 kg of weight: that’s roughly 2.8 kg/cm² of pressure. Well-tensioned webbing can lower peak pressures by up to 40%, spreading your weight so your seat doesn’t feel like a trampoline—or worse, a saggy hammock. By adjusting each strap to a target tension (typically 60–80 N per strap), manufacturers can fine-tune seating firmness. Tightening increases support, while a looser tension delivers a softer, more enveloping feel.

Common Webbing Systems

- Straight Straps: The simplest form—parallel runs of webbing secured across the frame. Best for lower-profile, lightweight chairs or benches.

- Sprung (Helical) Webbing: Incorporates a metal coil spring inside the strap for added resilience. Often found in mid-range sofas to combine ease of installation with extra “pop.”

- Layered Support: A base layer of straight webbing topped with sinuous springs or coil units creates a premium support system used in luxury furniture.

Manufacturing Workflow & Quality Control

| Step | Description | Typical Time |

|---|---|---|

| Frame Preparation | Cutting routing slots or attaching metal anchor plates | 5–10 minutes |

| Webbing Installation | Stretching & securing straps every 4–6 inches (10–15 cm) | 15–20 minutes |

| Tension Check | Using digital tension meters or “pinch tests” | 3–5 minutes |

| Final Inspection | Visual alignment & load testing | 5–8 minutes |

- Digital Tension Meters: Precision devices measure strap tension in newtons, ensuring each is within ±5 N of the target.

- Pinch Test: A quick manual check—pinch the center of a strap; it should snap back within 1–2 seconds, signaling proper tension.

- Load Testing: Random seats undergo a simulated 5,000-cycle loading to catch early failures before products ship.

This meticulous process isn’t just busywork; it means better longevity, fewer customer complaints, and a stronger reputation for quality.

Which Material Is Best for Upholstery Webbing?

Nylon offers top-tier strength (5,000–7,000 N) and excellent moisture resistance, but at a higher cost ($3.20 USD/m). Polyester balances durability (4,000–6,000 N) and affordability ($2.20 USD/m). Cotton provides natural aesthetics (1,500–2,500 N) and biodegradability at a budget price (~$1.10 USD/m), yet stretches more. Choose nylon for heavy use or outdoors, polyester for general residential/commercial seating, and cotton for light-use or eco-focused applications.

In-Depth Exploration

| Material | Tensile Strength (N) | Water Resistance | Cost (USD/m) | Stretch (%) | Biodegradable? |

|---|---|---|---|---|---|

| Nylon | 5,000–7,000 | Excellent | 3.20 | 2–4 | No |

| Polyester | 4,000–6,000 | Good | 2.20 | 5–8 | No |

| Cotton | 1,500–2,500 | Poor | 1.10 | 8–12 | Yes |

Why Nylon Might Be Your Go-To

- Heavy-Use & Outdoor: Nylon retains >90% tensile strength after 20,000 abrasion cycles and resists mildew.

- Low Maintenance: Minimal stretch means fewer re-tensioning visits.

- Trade-Off: Higher upfront cost, but lower lifecycle expense when you factor decades-long durability.

Why Polyester Is a Solid All-Rounder

- Versatility: Good strength and moisture resistance at a mid-range price.

- Moderate Maintenance: Expect to check tension every 4–5 years in heavy-use scenarios.

- Eco Note: Lower microplastic shedding compared to nylon under normal wear.

Why Cotton Still Has a Place

- Aesthetic & Eco Appeal: Soft, natural texture and fully biodegradable.

- Stretch Factor: Up to 12% elongation over time—plan for re-tensioning every 2–3 years under daily use.

- Cost Efficiency: Lowest upfront price, but potentially higher long-term maintenance costs.

Critically, the “best” material depends on your project’s priorities: maximum lifespan, budget constraints, environmental impact, or comfort profile.

How to Choose the Right Upholstery Webbing for Your Project?

Base your choice on usage frequency, maximum expected load, environmental conditions, and budget. Always select webbing with a working load limit at least 20% above your heaviest user. Opt for UV-stabilized synthetics for outdoor settings and factor in planned maintenance intervals for natural fibers.

Decision Checklist

| Factor | Key Question | Guideline |

|---|---|---|

| Usage Frequency | Daily, occasional, or rare? | Daily → nylon; Occasional → polyester |

| Max Load | Heaviest user weight + 20% safety margin? | 100 kg user → choose straps rated ≥120 kg |

| Environment | Indoor, outdoor, humid, or dry? | Outdoor → UV-treated nylon or polyester |

| Comfort Preference | Firm support or plush feel? | Firm → higher tension; Plush → elastic webbing |

| Budget & Lifecycle | Upfront vs. replacement cost over 10 years? | Compare total cost of initial + maintenance |

Pitfalls to Avoid

- Under-Rating Load: Using straps below your safety margin leads to sag and unhappy clients.

- Over-Tightening: Excessive tension can warp frames, snap straps, or crack wood.

- Frame Compatibility: Always measure frame channels—some don’t fit wider or thicker webbing.

- Skipping Prototype Tests: Testing samples on actual frames reveals fit and feel issues early.

Real-World Scenario

A trendy café in Miami initially chose cotton webbing for its outdoor lounge chairs. Six months later, the straps had stretched, sagged, and started to mildew. After switching to UV-stabilized nylon, they reported zero replacements over three years—saving over $2,000 USD in maintenance and downtime.

This example drives home the importance of aligning material choice with real-world conditions, not just cost per meter.

Are There Different Webbing Options for Various Furniture Types?

Yes! Sofas and chairs often use sinuous springs or layered spring systems for balanced support. Outdoor furniture demands UV-stable synthetics tested for 500+ hours of sun exposure and mildew resistance. Specialty seating like recliners rely on elastic webbing for smooth motion and rebound. Commercial/contract furniture must meet flame-retardant and ISO quality standards.

Sofas & Chairs

- Zigzag Spring Systems: Provide uniform support and a clean underside—ideal for slim frames.

- Layered Hybrids: Combine straight webbing with coil springs or sinuous layers to deliver luxury comfort without bulky profiles.

Outdoor & Patio Seating

- Marine-Grade Nylon: Treated for UV resistance (500+ hr test) and mildew protection—perfect for poolside loungers.

- High-Density Polyester: Flame-retardant and mildew-treated for covered patios in commercial spaces.

Recliners & Motion Chairs

- Elastic Rubber Webbing: Built to flex with moving parts, eliminating metal-on-metal noise.

- Cycle Testing: Top-quality elastics survive 20,000+ recline cycles without perceptible loss in tension.

Commercial & Contract Applications

- Regulatory Compliance: Must pass CAL117 (U.S.) or EN1021 (EU) flame tests and ISO 9001 quality audits.

- Durability Standards: Expect 5–7 years of daily use with no strap breakage or excessive sag.

By matching webbing specs to your furniture type, you ensure the right balance of comfort, safety, and longevity.

How Do You Secure Upholstery Webbing?

Secure webbing using spring-steel clips, corrosion-resistant staples, or webbing screws with serrated washers, spaced every 3–6 inches (8–15 cm). Even tension and protective backing (felt or rubber pads) prevent slippage and fiber wear. Regular inspections and re-tensioning keep your support system in top shape.

Fastening Methods

| Method | Hardware & Tools | Spacing | Pros | Cons |

|---|---|---|---|---|

| Spring-Steel Clips | Clips + clip insertion tool | 4–5 in (10–13 cm) | No frame damage, reusable | Higher clip cost |

| Corrosion-Resistant Staples | Pneumatic stapler + stainless staples | 3–4 in (8–10 cm) | Fast, low hardware cost | Can pinch fibers if overdriven |

| Webbing Screws | Screws + serrated washers, pilot drill | 5–6 in (13–15 cm) | Extremely secure, no slippage | Requires precise drilling, time-consuming |

Best Practices

- Measure & Mark: Pre-mark anchor points every 4–5 inches to ensure uniform support.

- Protective Backing: Place felt or rubber pads behind staples or clips to minimize fiber abrasion.

- Avoid Over-Tightening: Aim for target tension ±5 N to balance support and strap longevity.

- Routine Maintenance: Inspect and re-tension straps every 6–12 months in commercial settings; every 2–3 years for residential.

Tools of the Trade

- Digital Tension Meter (±2 N accuracy)

- Pneumatic Staple Gun (consistent staple depth)

- Clip Inserter (for easy clip seating)

- Pilot Drill (for screw mounts)

These simple steps and tools ensure your webbing stays put, giving you years of worry-free comfort.

What Are the Advantages of Using High-Quality Upholstery Webbing?

Premium webbing translates to better durability, consistent comfort, and lower lifecycle costs. High-tenacity fibers withstand millions of load cycles, maintain original tension, and resist moisture and UV damage. While upfront costs are higher, total expense over 10 years is often 20–40% lower than budget alternatives due to fewer replacements and labor savings.

In-Depth Exploration

| Quality Tier | Cost (USD/m) | Lifespan | Replacements/10 yrs | Total 10-Year Cost |

|---|---|---|---|---|

| Budget | 1.10 | 2 yrs | 5 | 5.50 |

| Mid-Range | 2.20 | 5 yrs | 2 | 4.40 |

| Premium | 3.20 | 10 yrs | 1 | 3.20 |

- Durability Gains: Premium nylon retains >90% tensile strength after 20,000 abrasion cycles; budget cotton may lose 30% in half that time.

- Comfort Consistency: High-end webbing holds original “bounce,” avoiding that depressing, bottom-out feeling cheaper straps deliver over time.

- Reduced Downtime & Costs: Fewer re-webbing jobs mean your furniture (or hospitality venue) stays in service, translating to 60% labor savings and fewer customer complaints.

Beyond the numbers, using top-tier webbing reflects well on your brand—whether you’re a bespoke furniture maker or a large-scale manufacturer. Customers notice comfort quality, and word-of-mouth travels fast.

How Can Szoneier’s Upholstery Webbing Meet Your Custom Needs?

Szoneier delivers fully customizable upholstery webbing in nylon, polyester, cotton, and unique blends. Choose your tensile strength (1,500–7,000 N), colors, prints, and pre-installed hardware. With low MOQs (100 m), 3–5-day prototypes, ISO9001 & OEKO-TEX™ certifications, and global shipping, Szoneier’s 18+ years of expertise guarantee fast, reliable solutions for every project.

Material & Strength Options

- Nylon: 5,000–7,000 N, mildew & UV resistant.

- Polyester: 4,000–6,000 N, cost-effective, moderate stretch.

- Cotton Blends: 1,500–2,500 N, eco-friendly, natural feel.

Custom Design & Hardware

- Colors & Patterns: Solid hues, stripes, cultural motifs, or your branded artwork printed directly on webbing.

- Pre-Installed Hardware: Clips, grommets, bonded ends, or screws—shipped ready to install.

Sampling, MOQ & Lead Times

- Low MOQ: 100 m minimum order.

- Rapid Prototyping: 3–5 days for samples to test fit, color, and tension.

- Lead Times: Standard production in 15–20 days; rush orders in 7–10 days.

Quality Assurance & Certifications

- ISO 9001: Strict quality management system.

- OEKO-TEX™ Standard 100: Tested free of harmful substances.

- In-House Testing: UV exposure, abrasion cycles, and tensile strength checks ensure consistency.

Global Support & Logistics

- Shipping Terms: CIF or FOB to North America, Europe, Australia, and beyond.

- Technical Help: Multilingual support teams advise on material selection, tension specs, and installation best practices.

Partnering with Szoneier means tapping into nearly two decades of R&D and manufacturing excellence—saving you time, headaches, and guesswork.

Ready to Transform Your Furniture with Rock-Solid Support?

Whether you’re crafting a luxury sofa, revamping antiques, or outfitting a busy hotel lobby, let Szoneier’s custom upholstery webbing be the backbone of your seating. Reach out today for a personalized quote and experience unmatched quality and service.