In an era when every shipment, every adventure, and every piece of precious cargo matters, ratchet straps stand as the unsung heroes of load securement. From long‑haul truckers crossing continents to weekend DIYers moving furniture, a single failure in load binding can mean damaged goods, costly delays, or even dangerous accidents. Ratchet straps combine simplicity with mechanical advantage—empowering users to generate hundreds or even thousands of pounds of tension with just a few pumps of a lever.

Ratchet straps are adjustable tie‑down tools that consist of high‑strength webbing and a ratcheting buckle mechanism. They provide controlled tensioning via a lever and gear system, lock securely under load, and feature various end fittings (S‑hooks, flat hooks, snap hooks) to anchor to points on trailers, racks, or vehicles. Ideal for transport, storage, and industrial applications, they ensure safety and stability across diverse environments.

Picture a filmmaker loading camera gear onto a van at dawn. As the ratchet clicks into place, the straps tighten snugly around the cases. In that moment, the noise of the city fades, replaced by the satisfying sound of securement. That click is peace of mind—and it’s why ratchet straps have become indispensable across industries. Let’s unravel what makes them tick.

What Components Make Up a Ratchet Strap?

A ratchet strap consists of four core components:

- Webbing: High‑strength belt made from nylon, polyester, or polypropylene.

- Ratchet Mechanism: Steel handle, drum, pawl, and gear assembly that creates and holds tension.

- End Fittings: Hooks or rings (S‑hooks, flat hooks, snap hooks) to anchor the strap.

- Free Tail & Label: Extra length of webbing for adjustment plus sewn‑in labels indicating Working Load Limit (WLL), break strength, and safety standards.

When you pick up a ratchet strap, what looks like a simple belt‑and‑lever tool is actually a carefully engineered system designed to generate massive tension safely and reliably. Let’s unpack each component in more detail.

| Component | Materials | Key Function |

|---|---|---|

| Webbing | Nylon, Polyester, Polypropylene | Bears the load—chosen based on stretch, UV resistance, and cost |

| Ratchet Mechanism | Heat‑treated carbon steel or zinc‑plated steel | Converts lever action into high tension, locks securely |

| End Fittings | Carbon steel, stainless steel, or zinc coating | Anchors the strap to fixed points |

| Free Tail & Label | Same webbing + printed/heat‑sealed label panel | Allows adjustment; provides load and compliance information |

1. Webbing (Load‑Bearing Belt):

- Nylon: Offers 10–15% elasticity, absorbing shocks during transport. It’s perfect for fragile cargo but may require retightening after long hauls or in humid conditions.

- Polyester: Stretches less than 5%, resists UV and moisture, and maintains tension over extended periods. This makes it the go‑to material for heavy‑duty, outdoor, and international shipping straps.

- Polypropylene (PP): The most cost‑effective option with low stretch. Suited for light to medium loads in indoor or controlled environments; however, UV exposure will degrade it faster than nylon or polyester.

2. Ratchet Mechanism (Tension Generator & Lock):

- Handle & Drum: Engineered to multiply user force—each pump of a 3‑inch handle can add hundreds of pounds of tension. High‑quality versions use heat‑treated steel gears for durability.

- Pawl & Spring: The pawl engages gear teeth to lock tension; a corrosion‑resistant spring keeps the pawl firmly engaged even after thousands of cycles. Robust design prevents accidental release under load.

3. End Fittings (Anchorage Points):

- S‑Hooks: Quick attachment but can rotate if not secured correctly—best used with D‑rings or fixed loops.

- Flat Hooks: Sit flush against anchor surfaces, reducing bending stress and minimizing the risk of hook failure.

- Snap Hooks: Include a spring‑loaded latch to prevent accidental unhooking in high‑vibration settings.

4. Free Tail & Label (Adjustment & Compliance):

- The free tail—typically 2–4 feet of extra webbing—allows you to thread the strap through the ratchet drum and adjust for varying load sizes.

- Labels are heat‑sealed or printed on durable material, displaying critical information: WLL (e.g., 2,000 lbs), break strength, webbing width, material type, batch number, and compliance standards (EN 12195‑2, DOT FMCSA). Keeping this label legible is essential for legal and safety reasons.

Each component is engineered with safety buffers—stitched seams often rated at 2.5× to 3× the strap’s WLL, corrosion‑resistant coatings on metal parts, and UV‑stabilizers in synthetic webbing. Together, they form a robust tie‑down solution trusted by truckers, equipment haulers, and DIY enthusiasts alike.

How Do Ratchet Straps Work?

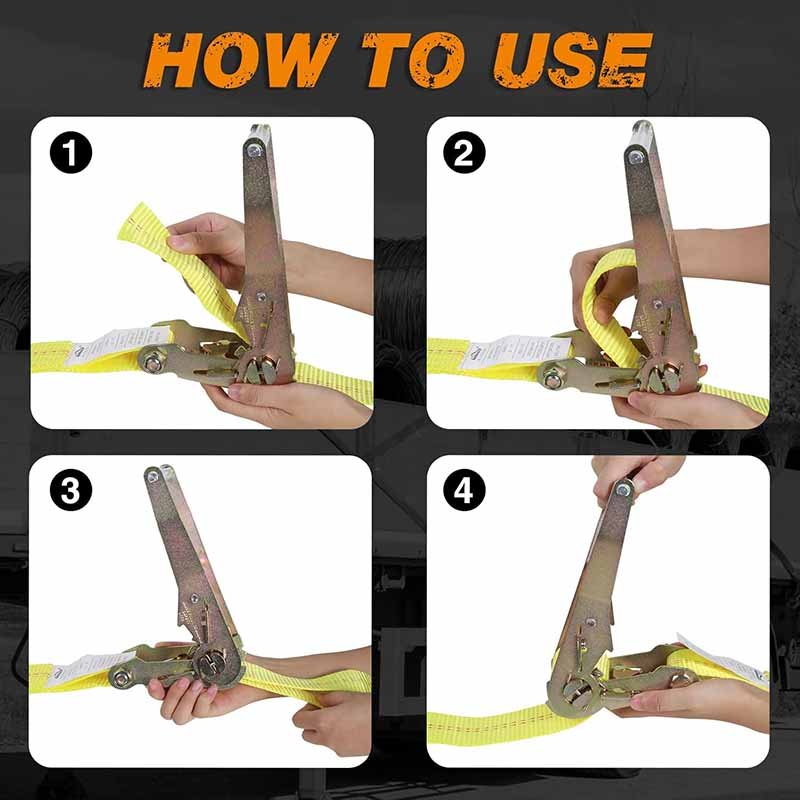

Ratchet straps operate by threading the free tail through the ratchet spool, then pumping the ratchet handle. Each pump winds webbing onto the drum, increasing tension. A pawl locks into gear teeth automatically, preventing back‑slip. To release, the user flips a release lever, disengaging the pawl, and unwinds the drum.

Initial Setup & Threading:

- Anchoring: Secure one end fitting to a fixed point (e.g., trailer D‑ring).

- Webbing Feed: Insert the strap’s free tail up through the bottom of the ratchet spool, then out through the top. Pull until taut—no twists or folds, which compromise strength.

Pre‑Tensioning:

- Pinch Method: Before full ratcheting, pinch the webbing and pull the free tail to remove slack. This step ensures smoother ratcheting and quicker tension buildup.

Full Tensioning Cycle:

- Lever Action: Each lever stroke wraps additional webbing onto the drum—typically 1–2 inches per stroke.

- Mechanical Advantage: The lever and gear ratio multiply the applied force. A 3‑inch handle stroke can generate hundreds of pounds of tension with minimal user effort.

- Automatic Locking: The pawl engages the gear teeth at each stroke, locking tension in place and eliminating the need to hold the handle.

Shock Load Management:

- Elastic vs. Inelastic Webbing: Elastic nylon can absorb sudden shocks (e.g., potholes), reducing stress on cargo. Polyester’s rigidity keeps heavy machinery immobile.

- Retightening: For long hauls, periodic checks and slight re‑tensioning keep the strap within safe limits.

Safe Release:

- Personal Protection: Wear gloves; stand clear of the strap’s recoil path.

- Release Lever: Fully depress the ratchet’s release lever to disengage the pawl. Slowly open the handle to let the drum unwind. Rapid or partial releases can cause uncontrolled recoil, risking injury.

Best Practices:

- Avoid Over‑Ratcheting: Excessive tension can stretch webbing beyond its elastic limit, reducing strength or permanently deforming the strap. Follow manufacturer recommendations for handle‑stroke count per load rating.

- Use Multiple Straps: For heavy or irregular loads, distribute force with parallel or crisscross configurations to prevent strap failure or load shift.

Which Materials and Webbing Types Are Best for Ratchet Straps?

Select polyester webbing for minimal stretch and UV resistance—ideal for long‑haul and outdoor use. Choose nylon webbing when shock absorption matters (e.g., motorcycles, delicate cargo). Use PP webbing for lightweight, cost‑sensitive applications indoors. Consider end‑use environment (UV, moisture, chemicals) and required WLL when selecting material.

The right webbing material balances strength, stretch, durability, and cost. Below is a comparative overview:

| Property | Nylon Webbing | Polyester Webbing | Polypropylene (PP) Webbing |

|---|---|---|---|

| Typical WLL (per 2″) | 1,000–3,000 lbs | 800–2,500 lbs | 500–1,500 lbs |

| Stretch Under Load | 10–15% | <5% | <5% |

| UV Resistance | Moderate (rated 500–1,000 hrs) | High (1,500–2,000 hrs) | Low (300–500 hrs) |

| Abrasion Resistance | High | High | Moderate |

| Moisture Absorption | Up to 5% weight increase | <0.5% weight increase | Negligible |

| Chemical Resistance | Good to acids & alkalis | Excellent | Good |

| Cost | $$$ | $$ | $ |

Nylon’s Shock‑Absorbing Role:

- When applied to cargo like motorcycles or delicate equipment, nylon’s elasticity reduces peak forces transmitted to tie‑down points.

- Downsides include moisture absorption—wet nylon is weaker and can stretch more, so periodic tension checks are needed.

Polyester’s Long‑Haul Reliability:

- With minimal stretch, imported machinery and shipping containers remain locked in position over extended journeys.

- Its UV stability prevents webbing degradation when straps remain exposed on open trailers.

PP’s Budget‑Friendly Trade‑Off:

- Best for non‑critical or infrequent use—warehouse bundling or indoor storage.

- Lower UV and abrasion resistance means limited outdoor lifespan.

Advanced Coatings & Treatments:

- UV‑Stabilizers: Extend service life by 20–50%.

- Anti‑Microbial Agents: Prevent mildew in marine or humid settings.

- Fire‑Retardant Finishes: Required for specialized applications (e.g., tunnel work).

Width & Thickness Considerations:

- Wider webbing increases contact area, reducing stress on cargo corners.

- Thicker weave enhances abrasion resistance but increases weight—find the balance based on application.

What Load Capacities and Strength Ratings Should You Look For?

Verify the Working Load Limit (WLL) and Break Strength on each strap’s label. WLL is typically 1/3 of break strength (safety factor of 3). For heavy industrial loads, choose straps with WLL ≥ 2,000 lbs. Always match total WLL (sum of parallel straps) to or above your cargo weight, and comply with relevant standards (EN 12195‑2, DOT FMCSA).

Understanding WLL vs. Break Strength:

- Break Strength: Maximum load before catastrophic failure—e.g., 6,000 lbs on a 2″ strap.

- Working Load Limit (WLL): Safe operational limit—usually one‑third or one‑fourth of break strength. A 6,000 lb break strength strap will have a WLL of about 2,000 lbs.

Safety Factors & Standards:

- EN 12195‑2 (Europe): Mandates a minimum safety factor of 3 for transport straps—Break Strength ≥ 3× WLL.

- DOT FMCSA (USA): Requires WLL labels and user instructions; safety factor typically 3:1.

- ASTM & ISO: Provide additional testing protocols for webbing abrasion, UV aging, and component fatigue.

Calculating Required Strap Count:

- Total Cargo Weight: Divide by strap WLL. Example: 4,000 lb load ÷ 2,000 lb WLL = 2 straps minimum.

- Dynamic Loads: Add 25–50% more capacity for shock or wind loads—round up strap count accordingly.

Labeling Clarity:

- Ensure labels remain legible—faded or missing WLL info invalidates the strap for legal transport.

- Szoneier’s custom labels include QR codes linking to test certificates, streamlining audits and compliance checks.

Real‑World Application Examples:

- Motorcycle Transport: 2 straps (2″ × 10 ft, WLL 2,000 lb) on front wheel uplift points, plus 2 on rear—total WLL 8,000 lb for a 700 lb bike.

- Palletized Goods: 4 straps crisscrossed over a 1,500 lb pallet, each WLL 1,500 lb—total WLL 6,000 lb.

How Do You Choose the Right Ratchet Strap for Your Application?

Match strap WLL to load weight, select webbing material based on environmental exposure, pick end fittings compatible with your anchor points, and choose strap width for stability. Consider length, color‑coding, and any custom branding or safety label requirements. Always prioritize compliance with relevant transport standards.

Load Characteristics:

- Weight: Heavier cargo demands higher WLL or multiple straps.

- Shape & Dimensions: Irregular loads benefit from wider webbing and multiple anchor angles to distribute tension evenly.

Environmental Factors:

- UV Exposure: Polyester with UV stabilizers for open‑air trailers.

- Moisture & Chemicals: Marine‑grade coatings and stainless‑steel fittings for saltwater or chemical transport.

- Temperature Extremes: High‑temperature nylon formulations vs. standard polyester for cold‑weather shrink resistance.

Anchor Point Compatibility:

- D‑rings & E‑track: Flat hooks or snap hooks that sit flush for E‑track rails.

- Fixed Loops & Bars: S‑hooks or J‑hooks for quick hooking/unhooking.

Length & Adjustment Range:

- Standard lengths range 6–30 ft. Longer straps allow versatile cargo arrangements but add weight and bulk.

- Custom lengths from Szoneier start at just 4 ft for small loads up to 50 ft for specialized applications.

Color‑Coding & Branding:

- Color Codes: Rapid visual identification of WLL—green for 1,000 lb, yellow for 1,500 lb, red for 2,000 lb.

- Private‑Labeling: Custom webbing print, logos, and safety instructions increase brand visibility and compliance.

Special Features:

- Anti‑Slip Coatings: Silicone or rubberized webbing surfaces prevent shifting on smooth cargo.

- Fire‑Retardant Webbing: Required for certain industrial or mining applications.

- Integrated Load Indicators: Visual markers that alert when tension drops below a set threshold.

What Safety Standards and Compliance Requirements Apply?

Key standards include EN 12195‑2 (European load‑securing), DOT FMCSA (U.S. transport safety), and ASTM D4869 (webbing abrasion). Compliant straps carry visible labels with WLL, break strength, batch numbers, and user instructions. For cross‑border shipments, ensure adherence to both origin and destination regulations.

EN 12195‑2 (Europe):

- Specifies test methods, safety factors, labeling, and user guides for lashing straps.

- Requires a minimum 3:1 ratio between break strength and WLL.

- Mandates durability tests: cyclic tension, UV exposure (up to 500 hrs), and abrasion.

DOT FMCSA (USA):

- Defines load‑tie‑down performance requirements for property‑carrying vehicles.

- Requires placards or labels with WLL, manufacturer name, and webbing material.

- Recommends periodic strap inspection and replacement intervals based on condition.

ASTM & ISO Standards:

- ASTM D4869: Abrasion resistance test for webbing materials.

- ISO 9001: Quality management system certification—ensures consistent manufacturing processes.

- ISO 4602: Specifies tie‑down fittings testing procedures.

Industry‑Specific Regulations:

- Mining & Heavy Industry: Mine Safety and Health Administration (MSHA) guidelines for flame resistance.

- Aviation: Federal Aviation Regulations (FAR) for tie‑down of ground equipment—often stricter WLL requirements.

- Marine: IMO (International Maritime Organization) standards for sea‑fastening equipment.

Label Integrity & Traceability:

- Szoneier’s straps feature heat‑sealed, tamper‑proof labels with QR codes linking to test certificates and batch records—streamlining compliance audits.

- Training materials and user manuals accompany each shipment to ensure end‑users understand proper inspection and use.

How Should You Inspect, Maintain, and Store Ratchet Straps?

Inspect straps before each use—look for cuts, abrasions, UV fading, and hardware corrosion. Clean with mild detergent and water; air‑dry away from direct sunlight. Store in a cool, dry place, hung or coiled loosely. Replace any strap showing damage or label unreadability.

Pre‑Use Inspection:

- Webbing: Check for frayed edges, snags, burns, chemical stains, or excessive UV bleaching. A 10% reduction in width can equate to a 20% strength loss.

- Hardware: Examine ratchet gears for smooth operation, spring tension, and pawl engagement. Look for rust or bent hooks.

- Labels: Ensure WLL and instructions remain legible—faded labels invalidate the strap’s certified rating.

Cleaning Protocols:

- Gentle Wash: Submerge in warm water with mild soap. Avoid harsh chemicals or bleach, which degrade fibers.

- Rinse & Air‑Dry: Thoroughly rinse to remove soap residue; hang in shade. Direct sunlight accelerates UV damage.

Storage Best Practices:

- Temperature: 40–80 °F (4–27 °C) ideal; avoid freezing or extreme heat (above 140 °F).

- Humidity: <60% relative humidity to prevent mildew and hardware corrosion.

- Organization: Hang straps on racks or coils loosely to prevent kinks. Avoid storing under heavy objects that can deform ratchet handles.

Periodic Load Testing:

- For critical applications, perform bench tests at 1.25× WLL annually—monitor elongation and spring tension.

- Maintain a log of tests linked to batch numbers (via QR code) for traceability.

End‑of‑Life Criteria:

- Immediate Retirement: Visible cuts exceeding 10% of webbing width, broken stitches, cracked hardware, or missing labels.

- Conditional Retirement: UV chalking, minor abrasion—subject to additional testing before re‑use.

- Document all retirements to ensure no uncertified strap re‑enters service.

What Are Common Mistakes and How Can You Avoid Them?

Avoid twists, over‑tensioning, using mismatched WLL straps, and ignoring label instructions. Always pre‑tension, use multiple straps for heavy loads, select the correct webbing material, and store/inspect straps properly. Training and adherence to standards prevent most ratchet strap failures.

Twisted Webbing:

- Impact: Twists concentrate stress at a single point, reducing WLL by up to 50%.

- Prevention: Always lay webbing flat before tensioning; visually confirm no twists.

Over‑Tensioning:

- Impact: Stretch beyond the elastic limit leads to permanent deformation and loss of strength.

- Prevention: Count handle strokes; refer to manufacturer’s ratchet‑stroke chart per load.

Using Incorrect WLL:

- Impact: Under‑rated straps can snap; over‑rated straps may damage fragile cargo.

- Prevention: Calculate cargo weight + dynamic forces; ensure total strap WLL ≥ that value.

Mismatched Straps:

- Impact: Different materials or WLL straps in one system can shift load unevenly.

- Prevention: Use identical straps in parallel; color‑coding helps ensure uniformity.

Ignoring Maintenance:

- Impact: UV damage, abrasion, or rusted hardware can develop unnoticed—leading to sudden failure.

- Prevention: Implement regular inspection and cleaning schedules; retire per end‑of‑life criteria.

Storage Errors:

- Impact: Coiled tightly or stored under weight can deform ratchet mechanisms or crease webbing.

- Prevention: Hang or loosely coil; keep in climate‑controlled storage.

Lack of Training:

- Impact: Improper use is the leading cause of strap failure.

- Prevention: Provide hands‑on training, clear manuals, and regular competency checks—tools Szoneier offers as part of its OEM service.

Ready to Customize Your Ratchet Straps?

At Szoneier, with 18+ years of expertise in webbing R&D and manufacturing, we deliver personalized ratchet strap solutions that exceed industry standards:

- Low MOQ & Free Samples

- Rapid Prototyping & Fast Sampling

- Custom Webbing & End Fittings

- Branded Labels & Compliance Documentation

- Global Logistics & Ongoing Support

Whether you need high‑strength polyester straps for international freight or shock‑absorbing nylon ties for sensitive equipment, we’ve got you covered. Reach out now to receive your free quote and sample kit—experience Szoneier’s commitment to quality, innovation, and customer satisfaction.