In today’s outdoor and industrial markets, webbing isn’t just about strength—it’s about standing up to the elements. Whether you’re crafting marine harnesses that battle sea spray or outdoor gear meant to keep campers dry through downpours, waterproof performance is critical. From high-altitude mountaineering straps to custom bag handles, a failure in water resistance can compromise safety, comfort, and longevity. Yet, not all webbings are created equal—and small choices in fiber, coating, or weave can yield outsized benefits in wet conditions.

Selecting the right webbing materials—such as hydrophobic polypropylene or coated nylon—paired with tight weave constructions and durable lamination, can boost water resistance by up to 90%. Combined with eco-friendly DWR treatments and rigorous AATCC 35 testing, these strategies ensure your straps, slings, and handles fend off moisture, resist mold, and maintain strength under load.

Imagine a climber midway up a glacier, the roar of a melting icefall echoing below. Their harness webbing, soaked by spray and slush, must hold firm. This story illustrates why every layer—from fiber selection to final finish—matters. Let’s dive in.

What Is Waterproof Webbing and Why Does It Matter?

Waterproof webbing repels or resists water intrusion, preventing saturation, mold growth, and strength loss. It’s vital for outdoor gear, marine applications, industrial slings, and safety harnesses where moisture can compromise performance and safety.

Webbing is a woven tape—often made of nylon, polyester, or polypropylene—used in applications where high tensile strength is essential. In many end-uses, the environment introduces water: rain, splash, humidity, or full immersion. Traditional untreated webbings absorb water, which can lead to:

- Strength Reduction: Nylon can lose up to 15% of tensile strength when wet, while polyester loses around 10%.

- Weight Gain: A water-saturated strap can weigh 20–30% more, altering load calculations.

- Mold & Mildew: Retained moisture fosters microbial growth, degrading fibers and endangering health.

- Abrasion & Freeze-Thaw Damage: Waterlogged webbings stiffen when frozen, leading to micro-cracks and accelerated wear.

Industries such as adventure tourism, military, maritime, and rope access demand reliable performance under moisture. For instance, coast guard harnesses must perform in saltwater spray without corrosion or mildew. Meanwhile, rope-access technicians rely on webbing to maintain strength after days of exposure to rain. Waterproofing isn’t a luxury—it’s a critical functional requirement.

Is Nylon Webbing Waterproof Compared to Polyester and Polypropylene?

Nylon is naturally absorbent (up to 8% moisture regain) and thus not fully waterproof; polyester absorbs only 0.4%, making it more water-resistant. Polypropylene, with virtually zero moisture uptake, offers the best intrinsic waterproofing but lower abrasion resistance.

Nylon Webbing:

- Pros: Exceptional tensile strength (breaking strength up to 8,000 lbs for 1″ webbing), good abrasion resistance.

- Cons: Hydrophilic nature means it soaks up water, swelling strands and reducing strength by up to 15% when wet. Dries slowly, risking mildew.

Polyester Webbing:

- Pros: Hydrophobic molecular structure leads to minimal water absorption (≈0.4% moisture regain). Strength reduction when wet is limited (~10%). UV-resistant.

- Cons: Slightly lower tensile strength than nylon at equal denier. Can feel stiffer in cold conditions.

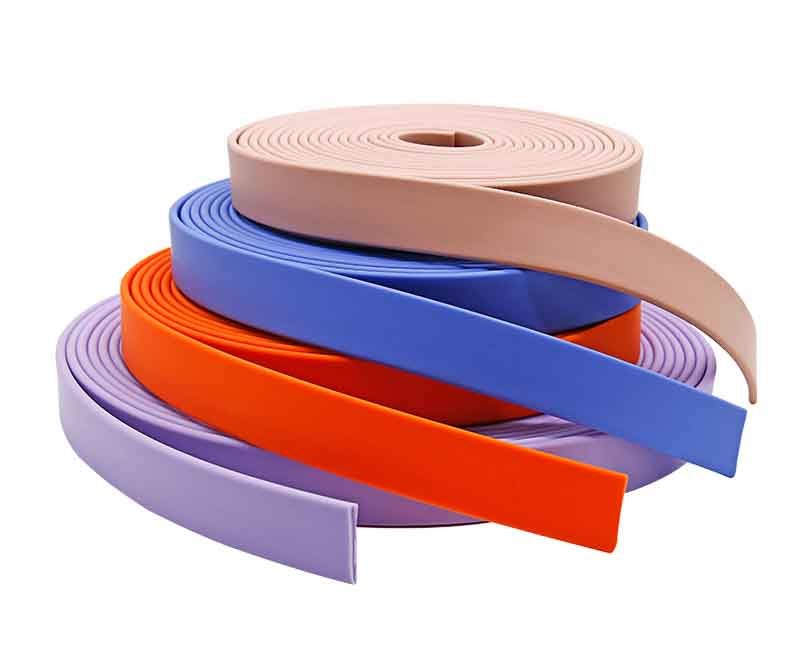

Polypropylene (PP) Webbing:

- Pros: Virtually zero water absorption, floats on water, dries instantly. Excellent chemical and mold resistance.

- Cons: Lower melting point (~160 °C), reduced abrasion resistance, tensile strengths about 25% lower than nylon.

Comparative Table:

| Property | Nylon | Polyester | Polypropylene |

|---|---|---|---|

| Moisture Regain | ~8% | ~0.4% | ~0% |

| Wet Strength Loss | Up to 15% | Up to 10% | Negligible |

| Tensile Strength | High (up to 8,000 lbs) | Moderate–High | Moderate |

| UV Resistance | Moderate | High | High |

| Abrasion Resistance | High | Moderate–High | Moderate |

| Drying Time | Slow | Moderate | Fast |

In critical applications—like safety harnesses—designers often favor polyester or PP for their hydrophobic qualities. However, nylon’s superior strength can justify additional waterproof coatings (see next section) when weight and durability are paramount.

How Do Coatings and Laminations Impact Webbing Water Resistance?

Coatings (PU, PVC, silicone) and laminated films create impermeable barriers that block water ingress. PU adds flexibility, PVC offers durability in harsh conditions, and silicone enhances UV stability, letting wet-prone webbings stay dry and strong.

Modern finishing technologies allow manufacturers to apply thin, uniform films or coatings onto fibers or fabric surfaces, drastically reducing water penetration without severely impacting flexibility or weight. Common approaches include:

Polyurethane (PU) Coatings:

- Advantages: High elasticity (elongation up to 300%), maintains hand-feel, lightweight (50–100 g/m²).

- Limitations: Moderate abrasion resistance; polymer microcracks over long-term flex cycles.

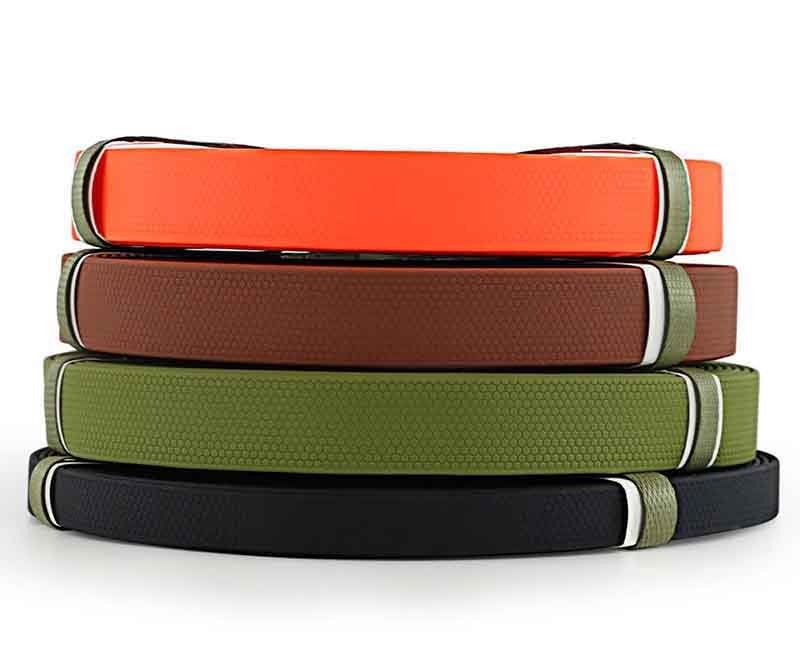

Polyvinyl Chloride (PVC) Coatings:

- Advantages: Excellent abrasion and chemical resistance; thick layers (100–250 g/m²) for heavy-duty industrial webbing.

- Limitations: Heavier, stiffer, potential plastic-izer migration in extreme temperatures.

Silicone Coatings:

- Advantages: Superior UV stability, hydrophobic surface energy (<20 mN/m), retains flexibility at –40 °C.

- Limitations: Higher material cost, requires specialized application.

Laminations:

- Film Lamination (PE, PET): Heat-bonded films yield nearly 100% impermeability. Ideal for inflatable structures or dry-bag straps.

- Foil Laminations: Aluminum or metallized films add reflective properties and thermal insulation but increase stiffness.

Hybrid Systems: Multi-layer laminates combining PU + PET films can achieve both breathability (via micro-perforations) and high water resistance (hydrophobic outer layer).

Case Study: A marine-grade sling produced for offshore oil platform maintenance utilized a 150 g/m² PVC coating over a polyester base. After 1,000 spray-down cycles (ISO 1817), tensile strength retained 92% of dry value—versus 78% uncoated polyester.

When selecting coatings, consider:

- End-Use Flexibility: Coatings should not compromise required bending and folding cycles.

- Weight Constraints: Lightweight coatings (<100 g/m²) suit backpacking and rescue gear; heavier coatings (>150 g/m²) suit industrial slings.

- Environmental Exposure: UV and chemical exposures guide material choice (silicone vs. PVC).

Which Weave Constructions Offer Superior Water Repellency?

Tighter weaves (e.g., basket or waffle) reduce spaces for water entry, while high-twist yarns and multi-bar configurations shed water more efficiently than simple plain weaves, enhancing repellency without coatings.

The structure of the weave dictates void spaces, capillary action, and ultimately how water interacts with the webbing:

Plain Weave:

- Structure: Simple over-under pattern.

- Pros: Balanced strength in warp and weft.

- Cons: Small voids between yarns can trap water.

Basket Weave:

- Structure: Groups of yarns woven together (2×2, 3×3).

- Pros: Denser surface, lower permeability.

- Cons: Slightly heavier, reduced dimensional stability.

Twill Weave:

- Structure: Diagonal ribbing pattern (2 over, 2 under, offset).

- Pros: Good drape and flexibility; water beads off diagonal ribs.

- Cons: Directional strength; more complex loom setup.

Satin/Leno Weave:

- Structure: Crossed warp yarns locked with filling yarn.

- Pros: Highly stable, very tight.

- Cons: Less abrasion resistance in float areas.

High-Twist Yarns & Mercerization:

- Impact: Tighter fiber crimps reduce capillary action. Mercerized cotton webbing exhibits up to 30% lower water uptake.

Multi-Bar Strap Designs:

- Multiple Layers: Two-layer webbings with offset weaves can interrupt water path.

Data Spotlight:

A comparative permeability test (hydrostatic head at 1 bar) showed:

- Basket weave polyester (600 D): 0.6 L/m²·s

- Plain weave polyester (600 D): 1.2 L/m²·s

- Twill weave nylon (600 D): 0.8 L/m²·s

Selecting the proper weave lets you tailor repellency at the fiber level—often at lower cost and weight than heavy coatings.

How Is Waterproof Performance Tested and Measured?

Waterproof webbing is evaluated via hydrostatic head, spray rating, and weight-gain tests (AATCC 35, ISO 811), ensuring products meet industry standards for barrier performance and durability under real-world conditions.

Standards bodies have defined quantitative tests for textiles and films:

- Hydrostatic Head (ISO 811): Measures pressure (mm H₂O) required for water to penetrate. Ratings >1,000 mm indicate fully waterproof.

- Spray Test (AATCC 22 & ASTM D2859): Simulates rain; fabric rated 0–100 based on surface wetting. Ratings ≥80 denote excellent repellency.

- Water Absorption (AATCC 39): Webbing immersed for set time; percentage weight gain quantifies absorption. Premium outdoor webbings aim for <5% gain.

- Wicking Test (AATCC 197): Evaluates capillary action along the webbing length. Lower wicking distance (<2 cm) preferred.

- Abrasion & Flex Testing: Coated webbings must maintain waterproof ratings after 10,000 flex cycles (Martindale) and 1,000 abrasion rubs (Wyzenbeek).

Testing Protocol Example:

A custom polyester webbing with silicone finish was tested:

- Hydrostatic Head: 1,200 mm

- Spray Rating: 90/100

- Weight Gain: 2.8% after 30 min immersion

- Wicking Distance: 1.2 cm in 5 min

Meeting these thresholds guarantees performance in gear like tarpaulins, safety harnesses, and marine slings—where failure can mean leak-through, corrosion, or catastrophic load loss.

What Treatment Methods Can Enhance Webbing’s Water Protection?

Durable water repellents (DWR), nano-finishes, and silane-based chemistries bond to fibers to shed water at the molecular level. Plasma treatments and eco-friendly PFC-free options offer lasting hydrophobicity without harmful fluorocarbons.

Beyond bulk coatings, surface treatments modify fiber wettability:

Durable Water Repellent (DWR):

- Mechanism: Low-surface-energy fluorinated or silicone polymers create beading.

- Longevity: Requires re-treatment after ~20 wash cycles unless advanced chemistries used.

Nano-Finishes:

- Silane/SiO₂ Nanoparticles: Form a silica network that repels water and oil.

- Benefits: Durable (>50 washes), PFC-free options available.

Plasma & Corona Treatments:

- Purpose: Increase fiber surface energy before coating, improving adhesion.

- Effect: Coatings last longer and resist delamination.

Green Chemistries:

- Acrylic & Silicone Based: PFC-free DWR that meets bluesign® and OEKO-Tex® standards.

- Biobased Waxes: Carnauba and other plant-derived wax emulsions offer moderate repellency (spray ratings ~70/100).

Szoneier can apply any of these treatments in-house, ensuring you meet stringent environmental and performance requirements.

Which Applications Demand the Highest Waterproof Standards?

Marine safety harnesses, inflatable rescue slings, and industrial chemical-handling straps demand hydrostatic head ≥1,200 mm, spray ratings ≥90, and weight gain <3%—to withstand saltwater, chemicals, and high-pressure wash-downs.

Use-case requirements vary widely:

Marine & Offshore Gear:

- Conditions: Saltwater corrosion, UV, high-pressure wash-downs.

- Specs: Hydrostatic head ≥1,500 mm, PVC coatings, stainless-steel hardware.

Industrial Slings & Lifting Straps:

- Conditions: Chemical exposure, abrasion, heavy loads.

- Specs: PVC or PU coatings ≥200 g/m², chemical-resistant finishes, safety factor ≥7:1.

Safety Harnesses & Rope Access:

- Conditions: Continuous UV exposure, rain, accidental immersion.

- Specs: Polyester base, silicone or PU top-coat, dynamic load testing in wet state.

Outdoor & Adventure Gear:

- Conditions: Rain, mud, freeze-thaw cycles.

- Specs: PP webbing for flotation, DWR treatments, reflective yarn integration.

Inflatables & Water Sports:

- Conditions: Full immersion, flex cycles, low temperatures.

- Specs: Film-laminated polyester, silicone coatings, thermal stress testing.

Each sector’s certifications (e.g., CE, ANSI, ISO) inform precise material and performance benchmarks.

How Should Designers Choose the Right Webbing for Maximum Water Resistance?

Balance fiber type, weave density, coating weight, and treatment methods against cost and MOQ. Prioritize inherent hydrophobicity (PP or polyester), tight weaves, lightweight coatings (PU/silicone), and eco-friendly DWR for your specific application to optimize performance and budget.

Step-by-Step Selection Guide:

- Define Performance Needs: Load, exposure, flexibility, lifespan.

- Choose Base Fiber: PP for floatation, polyester for UV and abrasion, nylon for strength plus coating.

- Select Weave Structure: Basket or twill for tighter density; consider yarn twist.

- Determine Coating/Treatment: PU for flexibility, PVC for heavy duty, nano-silane for eco-friendly repellency.

- Test Early & Iterate: Prototype small batches, conduct AATCC and ISO tests in real-world simulations.

- Optimize Cost & MOQ: Szoneier’s low MOQ (50 pcs) lets you trial multiple options before scaling.

Cost vs. Performance Matrix (per meter):

| Option | Base Cost (USD) | Coating Cost (USD) | Treatment Cost (USD) | Total Cost | Waterproof Rating |

|---|---|---|---|---|---|

| Polyester + DWR | 0.80 | 0.20 | 0.10 | 1.10 | Spray 80/100 |

| Nylon + PU | 1.00 | 0.30 | 0.05 | 1.35 | Hydrostatic 800 mm |

| PP Untreated | 0.60 | 0.00 | 0.00 | 0.60 | Negligible absorb. |

| Polyester + Silicone | 0.80 | 0.40 | 0.15 | 1.35 | Hydrostatic 1200 mm |

By following this framework, you can tailor your webbing to exact specs—reducing over-engineering costs while ensuring robust water resistance.

Ready to develop waterproof webbing that meets your toughest requirements? Contact Szoneier today for custom samples, free design consultation, and rapid prototyping. Let our 18 years of expertise deliver the perfect balance of strength, flexibility, and moisture protection—built just for your product.

Request a Quote from Szoneier Now